Rotating arm crane pipe for loading hydrochloric acid

A technology of a swivel arm and a crane tube, which is applied in the field of hydrochloric acid loading jib crane tube, can solve the problems of troublesome construction of trestle bridges at loading and unloading places, rubber tube rupture and acid leakage, and rubber tube bending difficulty, etc. The degree of construction and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

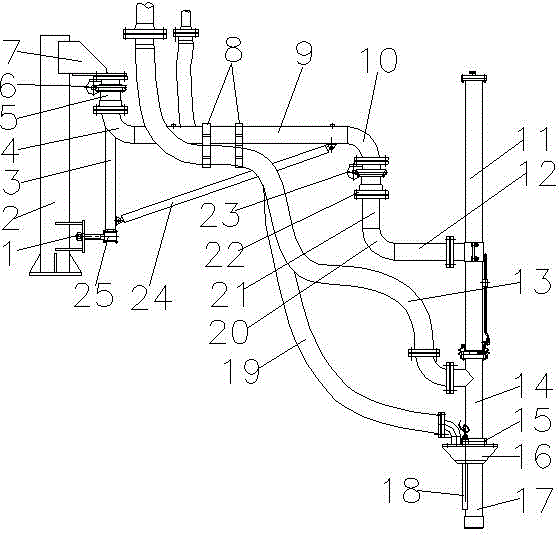

[0017] like figure 1 Shown, a kind of hydrochloric acid loading arm crane tube, it comprises support frame assembly, arm assembly, hydraulic cylinder 11, vertical pipe 14, sealing cap 16, telescopic tube 17, liquid level gauge 18, gas phase hose 19 and liquid With respect to the hose 13, the support frame assembly includes a column 2, a bracket 7 fixed to the upper and lower ends of the column 2, a seat frame 1, a support 3, a rotating support seat 25, a first rotary joint 5, and a first air motor 6 , the bracket 7 and the seat frame 1 are fixed along the direction of the same vertical line, and the rotary support seat 25 is provided on the seat frame 1, the first rotary joint 5 is provided at the lower end of the support frame 7, and the The first rotary joint 5 is driven by the first air motor 6, and a support 3 is provided between the rotary support base 25 and the first rotary joint 5; The first elbow 4 below, the inner arm 9 connected to the other end of the first elbow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com