Wood formwork fixture for building concrete construction and operation method of wood formwork fixture

A wood formwork and concrete technology, which is applied in formwork/formwork/work frame, construction, building structure, etc., can solve the problems of small market prospect, low secondary use rate, and many procedures, and achieve broad market prospect and promotion Application value, high secondary usage rate, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

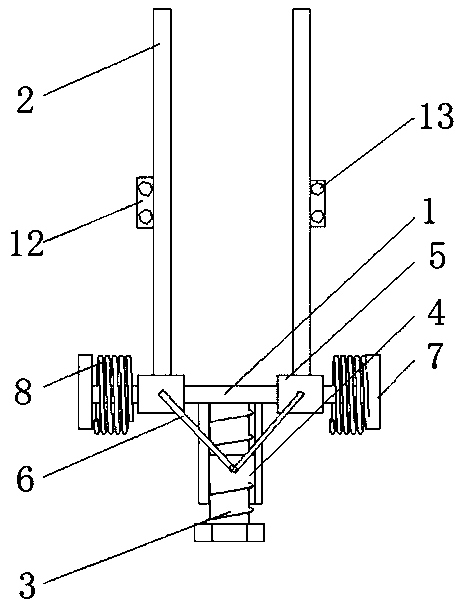

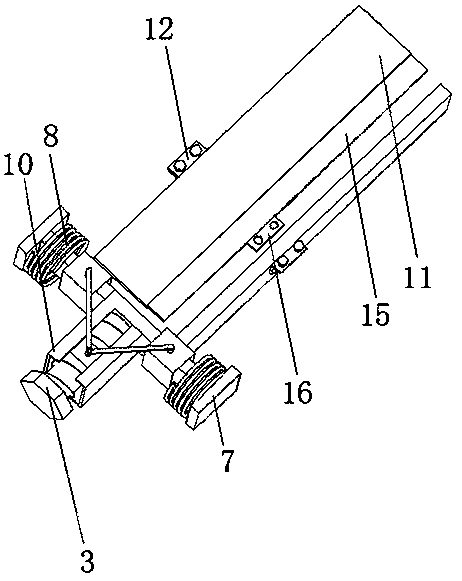

[0028] refer to Figure 1-2 , a wooden formwork fixture for building concrete construction, comprising a side plate 1 and a splint 2, the side plate 1 and the splint 2 are placed at right angles, the outer wall of the side plate 1 is connected with a bolt 3, the outer wall of the bolt 3 is threaded with a threaded sleeve 4, and the splint 2 is A casing 5 connected to the side plate 1 is connected, the outer wall of the threaded sleeve 4 is hinged with a connecting rod 6, and the end of the connecting rod 6 away from the threaded sleeve 4 is hinged with the sleeve 5, and the outer wall of the side plate 1 is sleeved with a spring 8, The spring 8 is connected between the limit block 7 and the casing 5; when it is necessary to pour concrete or change the size of the formwork, the bolt 3 is rotated to make the threaded sleeve 4 move away from the side plate 1 and move in the direction of the bolt 3, so that the threaded sleeve 4 Drive the connecting rod 6, so that the connecting r...

Embodiment 2

[0030] refer to Figure 1-3 , a wooden formwork fixture for building concrete construction, which is basically the same as Embodiment 1, furthermore, the outer wall of the side plate 1 is excavated with a first threaded hole 9 that matches the bolt 3; to prevent shaking when the bolt 3 is rotated, there is It is beneficial to the stability of the wooden formwork fixture.

[0031] The outer wall of the side plate 1 is connected with a groove 10, and the threaded sleeve 4 is slidably connected to the inner wall of the groove 10; the threaded sleeve 4 is slidably connected in the groove 10, so as to prevent the threaded sleeve 4 from twisting when the bolt 3 is rotated, so as to improve the service life of the fixture.

Embodiment 3

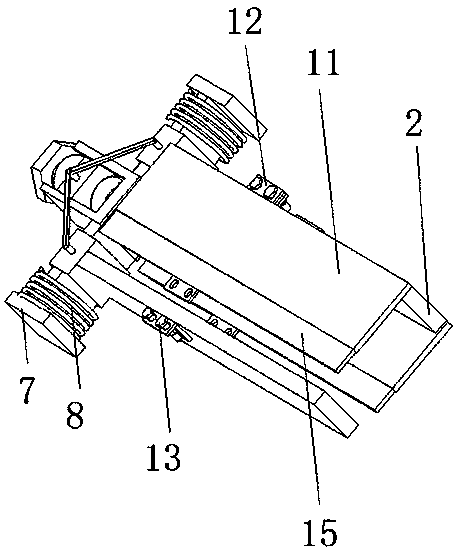

[0033] refer to Figure 1-4 , a wooden formwork fixture for building concrete construction, which is basically the same as that of Embodiment 1, and furthermore, the outer wall of the splint 2 is connected with a cover plate 11, and the cover plate 11 and the outer wall of the splint 2 are connected with a fixed plate 12 that wants to be matched. The outer wall of the plate 12 is dug with a second threaded hole 13, and the second threaded hole 13 is connected with a screw 14; the fixture can be sealed and the concrete can be poured conveniently, and the screws 14 are used to pass through the second threaded hole through the cooperation between the fixed plates 12 13. Fix the wooden formwork, which is beneficial to building construction and easy to remove the formwork.

[0034] A cavity is excavated inside the cover plate 11, and a pumping plate 15 is slidingly connected in the cavity, and the outer wall of the pumping plate 15 is connected with a positioning plate 16 that matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com