Dam bag of rubber dam and processing technology thereof

A dam bag and rubber technology, applied in the field of rubber dam dam bag and its processing technology, can solve the problems of high fluidity, easy aging of flat pads, hidden safety hazards, etc., achieve single-width increase, improve appearance quality, and improve safety The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

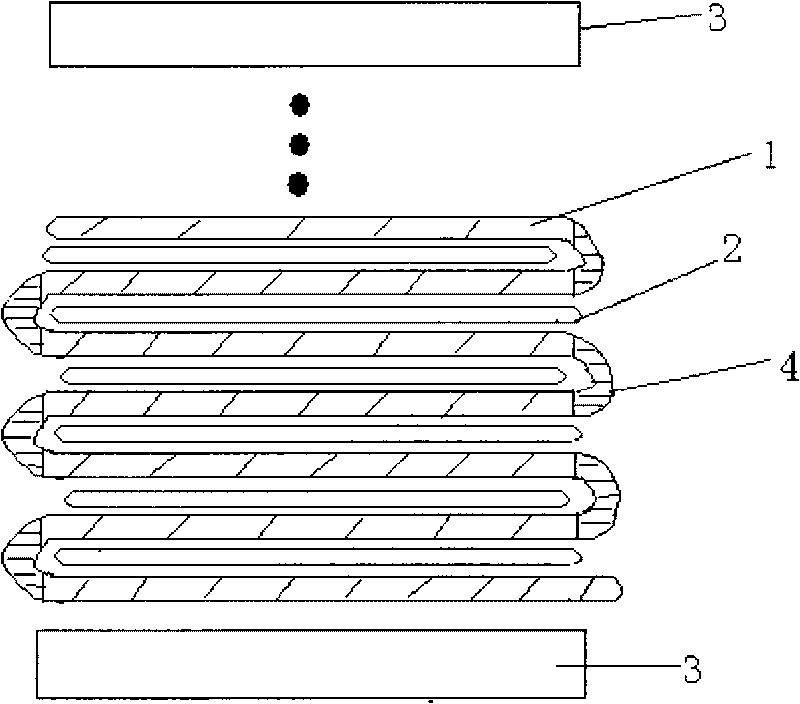

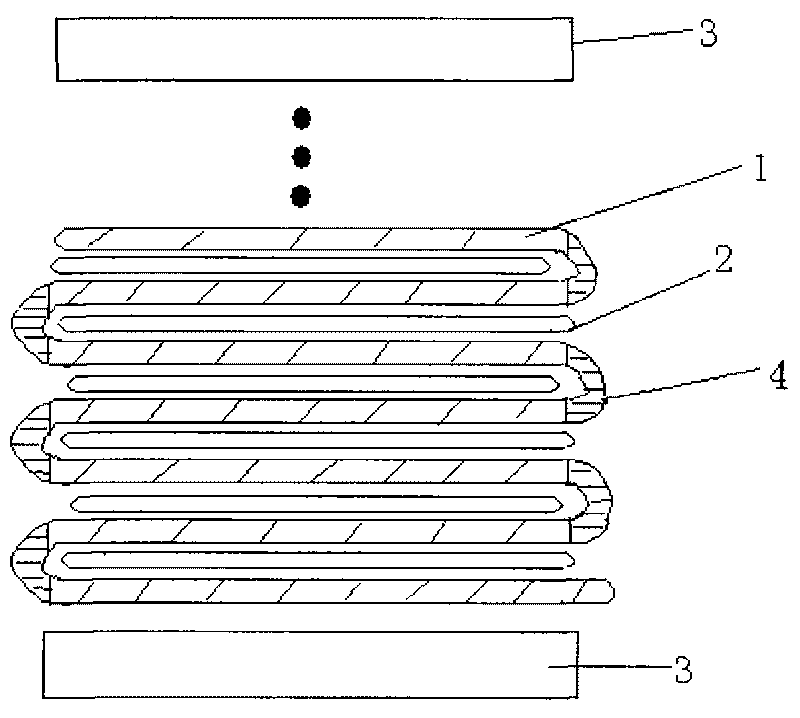

[0027] A kind of rubber dam bag and its processing technology reference attachment figure 2 A rubber dam dam bag includes dam bodies 1 connected in sequence, two adjacent dam bodies 1 are connected by a section of unvulcanized soft body section 4, the dam body 1 and the soft body section 4 are of an integral structure, the dam body The number of bodies 1 is equal to 2, and the soft body segment 4 is rubber soft body.

[0028] A kind of processing technology of rubber dam dam bag of the present embodiment comprises following processing steps:

[0029] 1. Fold

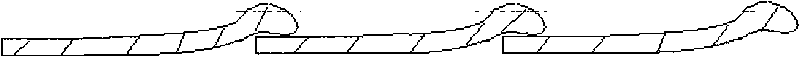

[0030] Measure a section of length from the starting end of the dam bag and place it outside the width of the single-width vulcanizing machine, then lay the dam body 1 of the dam bag on the table of the single-width vulcanizing machine with the width of the single-width vulcanizing machine, and fold it up once to form a fold The interlayer, the folding route is S-shaped.

[0031] 2. Isolation

[0032] A non-woven fa...

Embodiment 2

[0039] A kind of rubber dam dam bag of the present embodiment and production method thereof refer to attached figure 2 , the difference from Example 1 is that the number of dams 1 is five.

[0040] A kind of production method of rubber dam dam bag of the present embodiment comprises the following processing steps:

[0041] 1. Fold

[0042] Measure a section of length from the starting end of the dam bag and place it outside the width of the single-width vulcanizing machine, and then lay the dam body 1 of the dam bag on the table of the single-width vulcanizing machine with the width of the single-width vulcanizing machine, and fold upwards sequentially to form a folded interlayer. Fold up 4 times, and the folding line is 2-shaped.

[0043] 2. Isolation

[0044] A non-woven fabric layer 2 whose size matches the area of the folded surface and contains a release agent is laid in the folded interlayer, so that the adjacent folded surfaces do not stick together during vulcani...

Embodiment 3

[0051] A kind of rubber dam bag of present embodiment and production method thereof refer to appendix figure 2 , and the difference with embodiment 1 is that the quantity of dam body 1 is 10.

[0052] A kind of production method of rubber dam dam bag of the present embodiment comprises the following processing steps:

[0053] 1. Fold

[0054] Measure a section of length from the starting end of the dam bag and place it outside the width of the single-width vulcanizing machine, and then lay the dam body 1 of the dam bag on the table of the single-width vulcanizing machine with the width of the single-width vulcanizing machine, and fold upwards sequentially to form a folded interlayer. Fold up 9 times, and the folding route is S-shaped.

[0055] 2. Isolation

[0056] A non-woven fabric layer 2 whose size matches the area of the folded surface and contains a release agent is laid in the folded interlayer, so that the adjacent folded surfaces do not stick together during vul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com