Adaptive waterproofing structure for T-joint part of mechanical method contact passage

A communication channel and waterproof structure technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of difficult to ensure the safety of tunnel construction, numerous construction steps, low construction efficiency, etc., and achieve good waterproof effect and long-term strength Steady rise, the effect of ensuring construction safety and project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

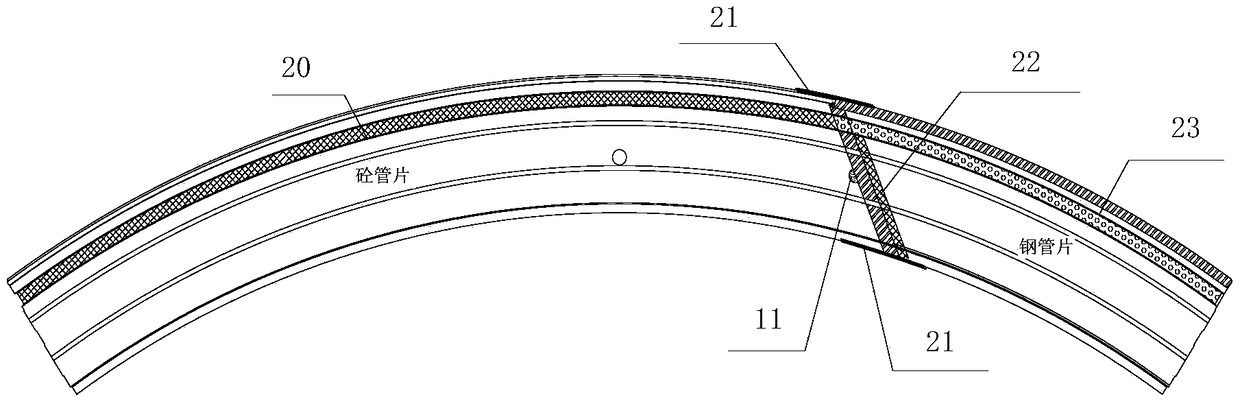

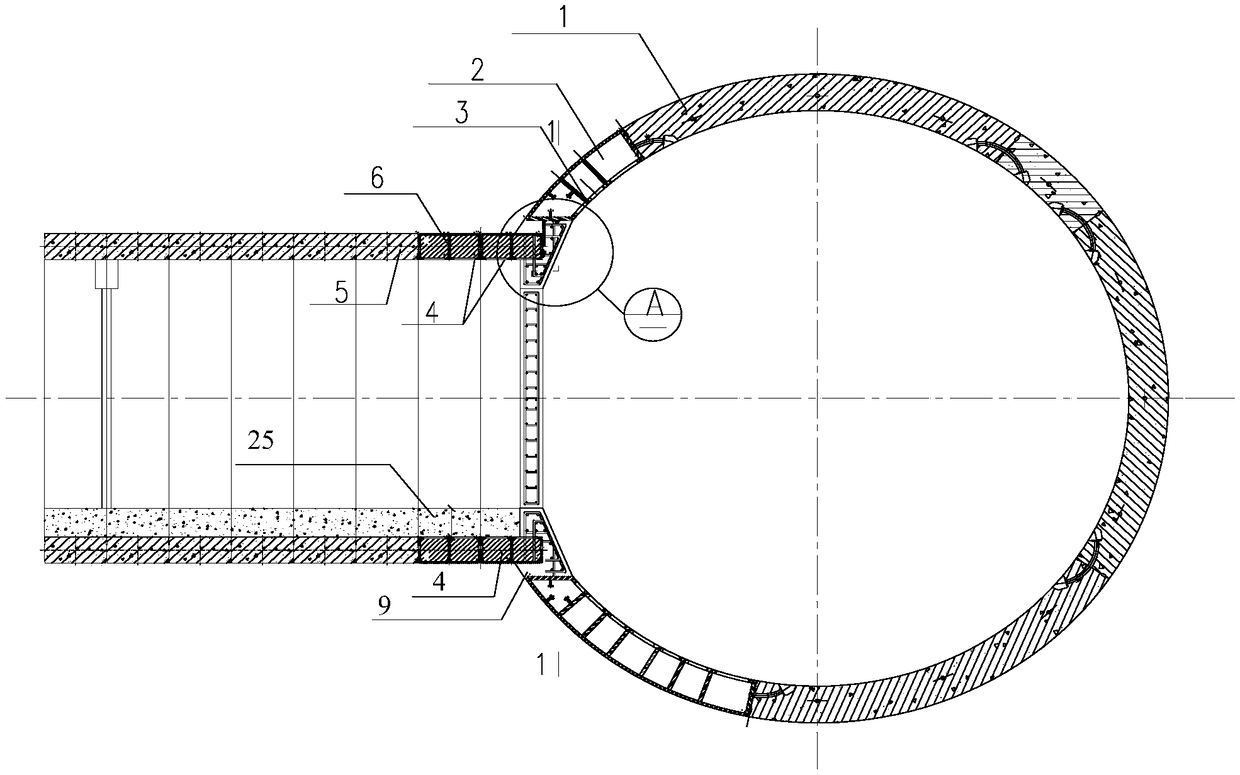

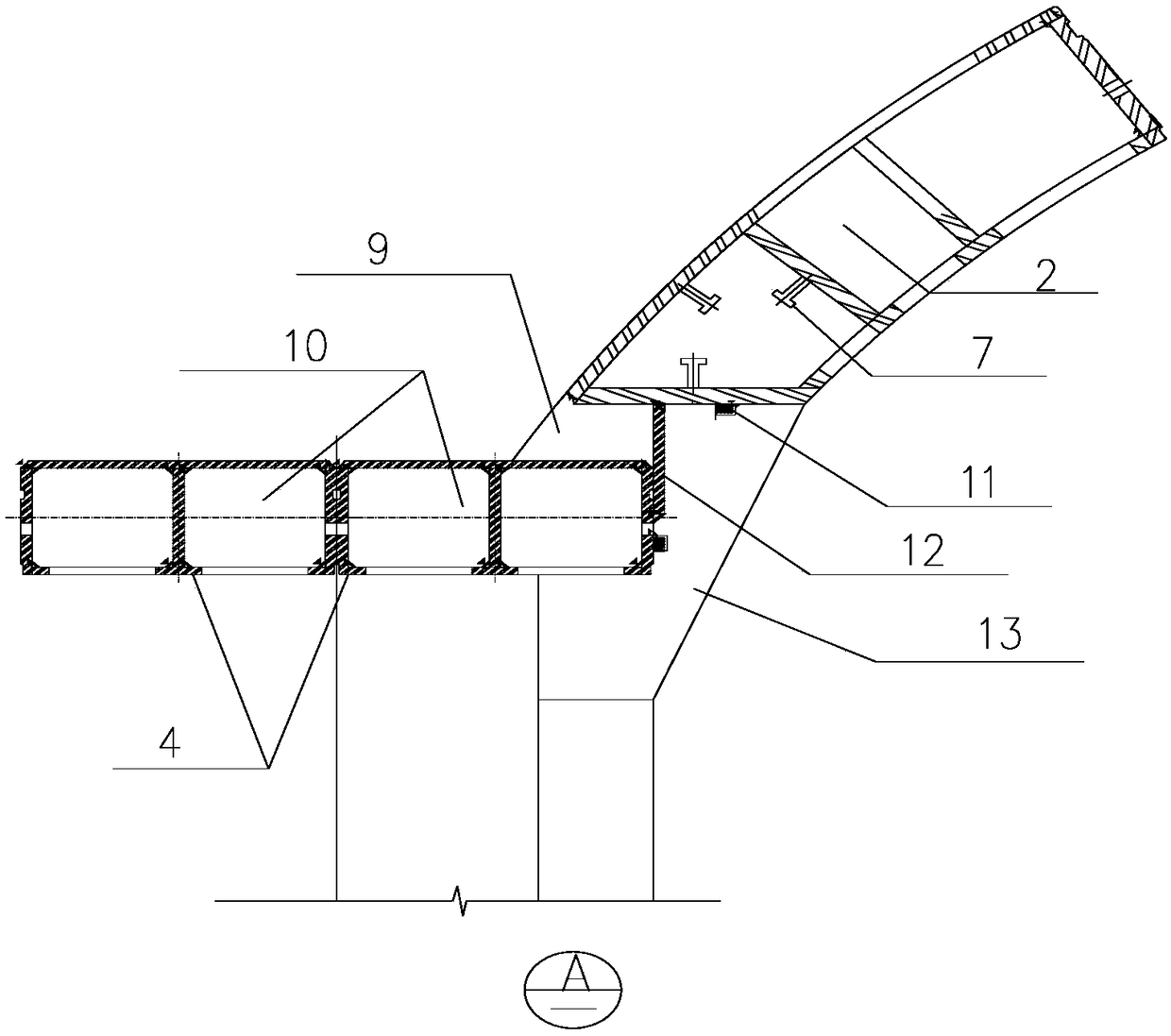

[0031] Such as Figure 1 to Figure 5 As shown, the self-adaptive waterproof structure of the T-joint part of the mechanical method communication channel is mainly provided with an outsourcing waterproof system at the T-joint part of the shield tunnel and the communication channel, and the waterproofing of the 7-ring steel-concrete composite segment structure of the shield tunnel and the back wall Waterproofing of grouting body, waterproofing of the segment structure of the communication channel, water sealing of the grouting body behind the wall, and sealing of the gap between the steel plate 12, the steel tube segment of the communication channel 4, and the composite segment 2 of the shield tunnel. Form a set of waterproof system for the T-junction between the communication channel and the shield tunnel. Water-expandable rubber strips 11, water-expandable gaskets 20, cement-based permeable crystalline coatings 21, and water-expandable Expanded rubber sheet 22, EPDM rubber el...

Embodiment 2

[0051] The first phase of Ningbo Rail Transit Line 3 is the connecting channel between the southern business district station and the Yinzhou District Government Station. The starting mileage from the southern business district station to Yinzhou District Government Station is ZDK7+794.800, and the terminal mileage is ZDK8+754.100. The tunnel length is about 959.3m. The mileage of the communication channel is ZDK8+214.377, the buried depth is 16.94m, and the line spacing is 17m. The communication channel is constructed by mechanical method. The diameter of the shield tunnel is 6200mm, the thickness of the segment is 350mm, and 8 grouting holes are arranged around the opening of the communication channel. The excavation diameter of the communication channel is 3290mm, the diameter of the small segment is 3150mm, and the ring width is 550mm. Five grouting holes are arranged in each ring of the small segment of the communication channel.

[0052] 1. Waterproofing of longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com