Construction method for movable mold frame for lock chamber wall of ship lock

A technology of mobile formwork and construction methods, which is applied to ship locks, ship lifting devices, climate change adaptation, etc., can solve the problems of large ship lock chamber walls, difficult construction, and large pouring volume, so as to improve the appearance quality, High construction efficiency and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

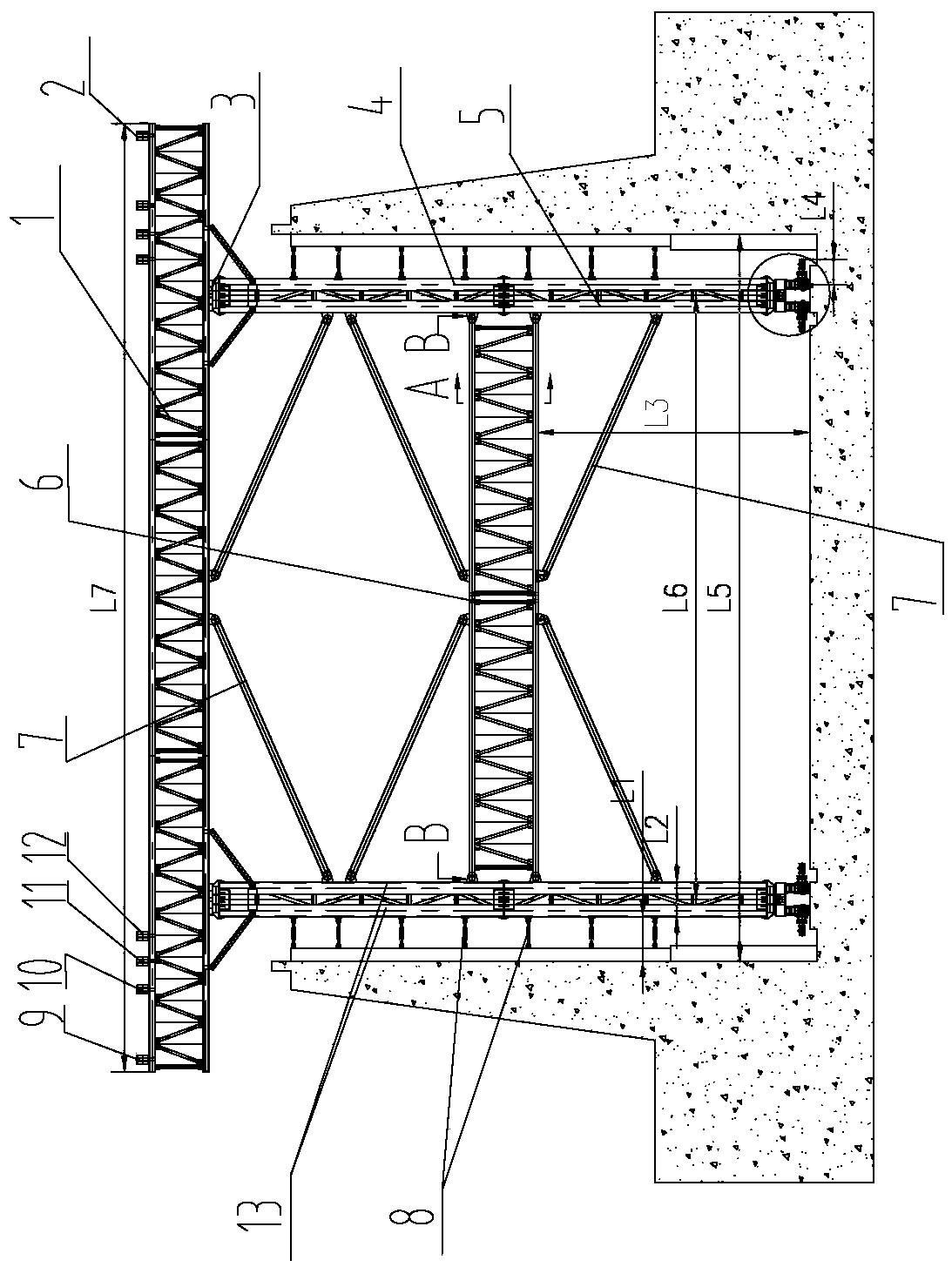

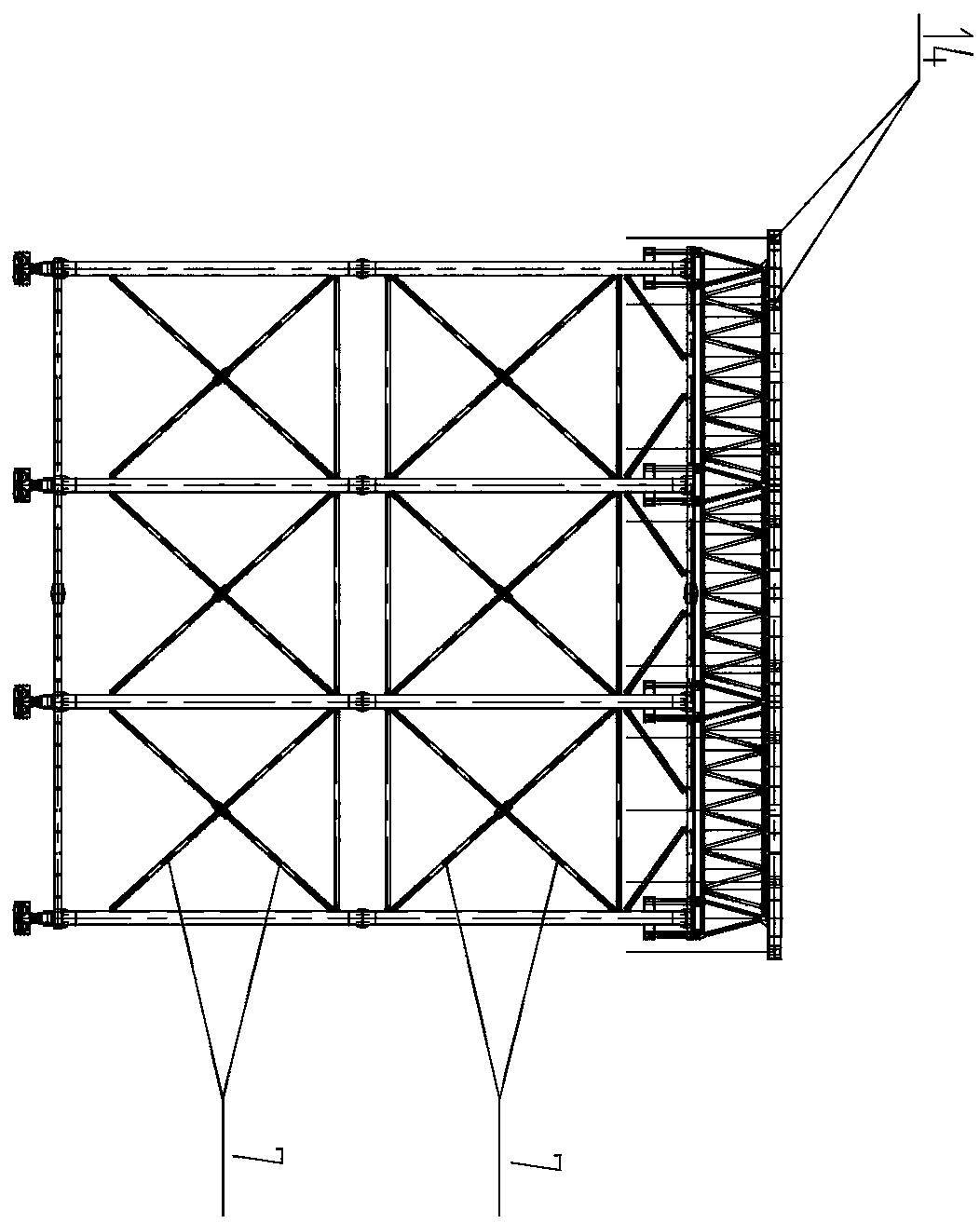

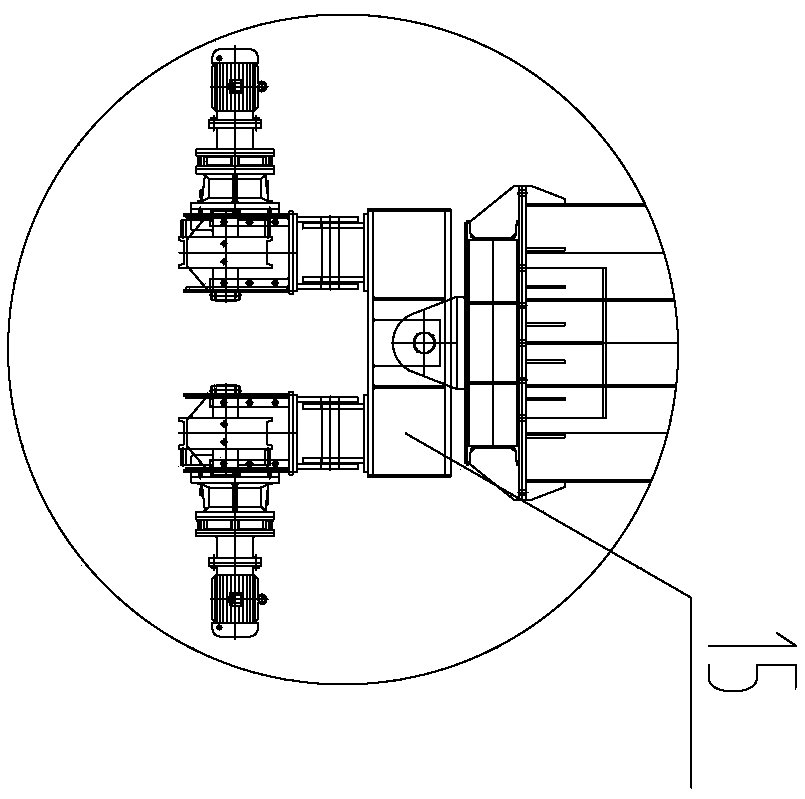

[0037] figure 1 Front view of the mobile formwork for the lock chamber wall; figure 2 Left view of the mobile formwork for the lock chamber wall; image 3 is the structural schematic diagram of the ground beam; Figure 4 for along figure 1 B-B line sectional view of ; Figure 5 for along figure 1 The A-A line sectional view shows:

[0038] The main dimensions involved in the figure are as follows: L1: 1411.5, L2: 1077.0, L3: 8594.5, L4: 980, L5: 23000.0, L6: 19100.0, L7: 30000.0;

[0039] The Yingshang double-track ship lock is located on the channel of the Shaying River. The ship lock level is IV, and the designed maximum ship tonnage is 500 tons, taking into account 1,000 tons. The double track lock is Class navigable building, the size of the lock chamber is 23×200×4(m) (clear width of the lock chamber×effective length×depth above the sill), the ship lock operates with one-way water head, and the designed maximum water head is 7.96m, and the water delivery system a...

Embodiment 2

[0079] The concrete described in step ⑤ in Example 1 is composed of the following raw materials in parts by weight: 40 parts of cement, 40 parts of stone, 60 parts of water, 5 parts of fly ash, 2 parts of water reducing agent, polyarylether ether 5 parts of nitrile modified phenolic resin, 8 parts of steel fiber, 2 parts of sodium hydroxymethyl cellulose and 1 part of sodium bentonite; the water reducer is composed of calcium lignosulfonate and 2,6 - Composition of sodium di-tert-butylnaphthalene sulfonate;

[0080] The polyarylether ether nitrile modified phenolic resin is prepared according to the following steps: in parts by weight, mix 100 parts of phenol and 45 parts of solid paraformaldehyde, heat to 40°C, stir and dissolve, add polyarylether ether 10 parts of nitrile, stirred for 15 minutes, added 1.0 part of maleic acid, heated to 100°C, kept warm for 3 hours, cooled to 50°C, dehydrated by distillation under reduced pressure, cooled to 20°C to obtain polyarylether ethe...

Embodiment 3

[0082] The concrete described in step ⑤ in Example 1 is composed of the following raw materials in parts by weight: 50 parts of cement, 50 parts of stone, 70 parts of water, 10 parts of fly ash, 5 parts of water reducing agent, polyarylether ether 10 parts of nitrile modified phenolic resin, 12 parts of steel fiber, 5 parts of sodium hydroxymethyl cellulose and 3 parts of sodium bentonite; the water reducer is composed of calcium lignosulfonate and 2,6 - Composition of sodium di-tert-butylnaphthalene sulfonate;

[0083] The polyarylether ether nitrile modified phenolic resin is prepared according to the following steps: in parts by weight, mix 100 parts of phenol and 45 parts of solid paraformaldehyde, heat to 40°C, stir and dissolve, add polyarylether ether 10 parts of nitrile, stirred for 15 minutes, added 1.0 part of maleic acid, heated to 100°C, kept warm for 3 hours, cooled to 50°C, dehydrated by distillation under reduced pressure, cooled to 20°C to obtain polyarylether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com