Direct-injection sprue type passive needle valve

A passive, needle valve technology, applied to the needle valve field in the injection molding field, can solve the problems of long maintenance time, poor color changeability of the needle valve, and clean flushing, shortening maintenance time, simplifying loading and unloading, and reducing flow resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

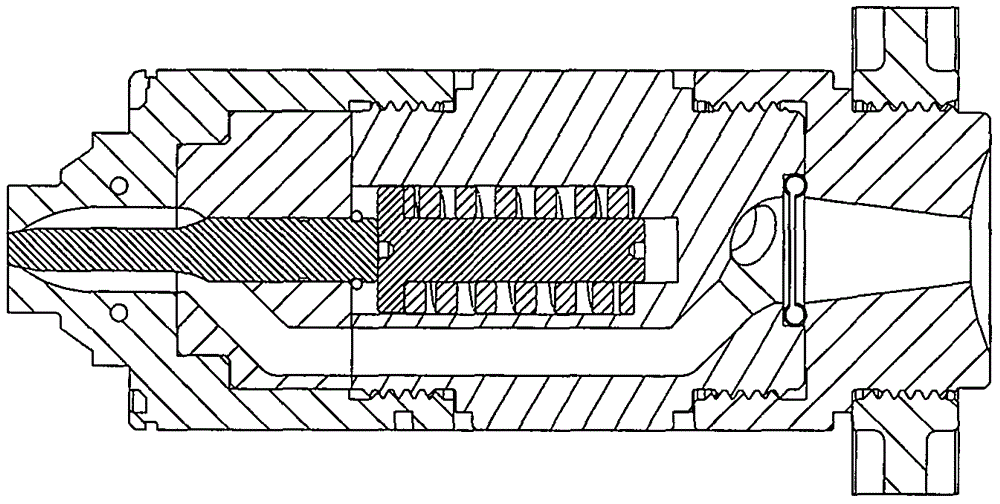

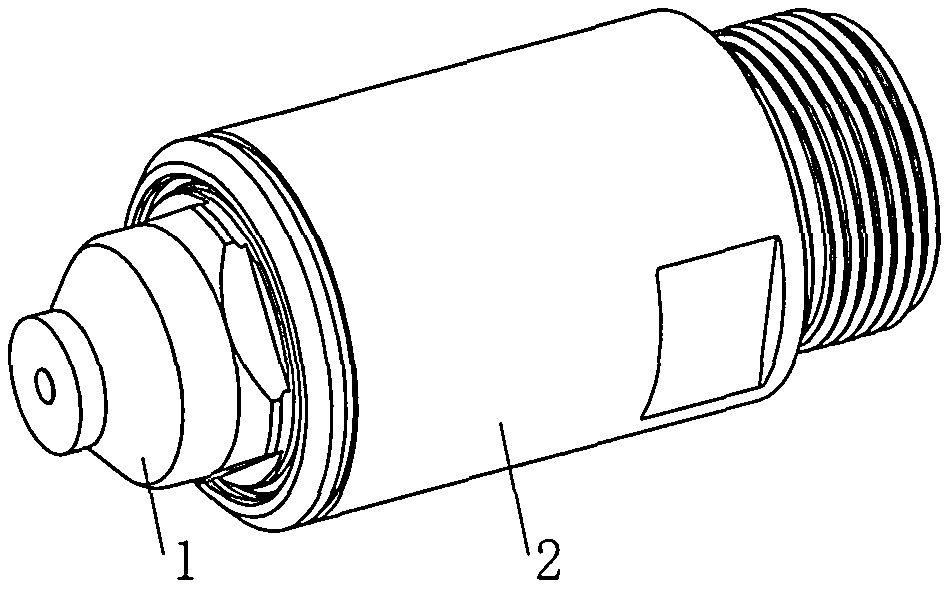

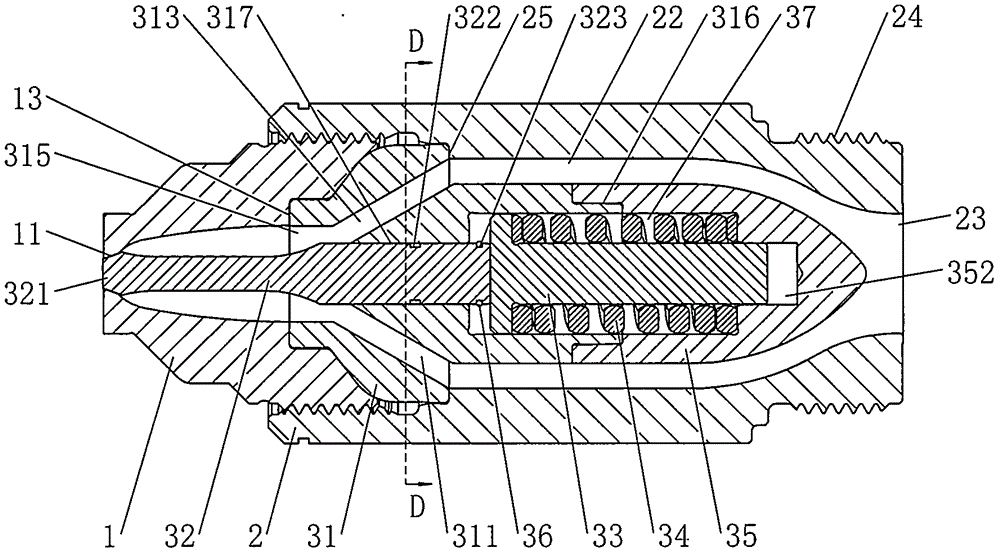

[0030] see Figure 2 ~ Figure 11 , the direct shot gate passive needle valve of the present invention includes a valve nozzle 1 , a valve body 2 and a valve core 3 . The small end of the valve nozzle 1 is provided with a tapered central injection port 11 . The center of the valve body 2 is provided with a through hole that smoothly transitions from the large hole 22 to the small hole 23, and one end of the valve body 2 is also provided with a cavity structure 21 with an internal thread and communicates with the large hole 22 of the through hole. , The outer wall of the other end of the valve body 2 is provided with an external thread 24, which can be connected to a flange or a sleeve so as to increase the length of the needle valve. The valve core 3 is composed of a valve core body 31, a valve needle 32, a push rod 33, a spring 34, a valve cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com