Fabric hot-pressing separation type calendaring processing technology

A processing and separate technology, applied in the field of textile fabrics, to save dye consumption, improve reliability and safety, and improve hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

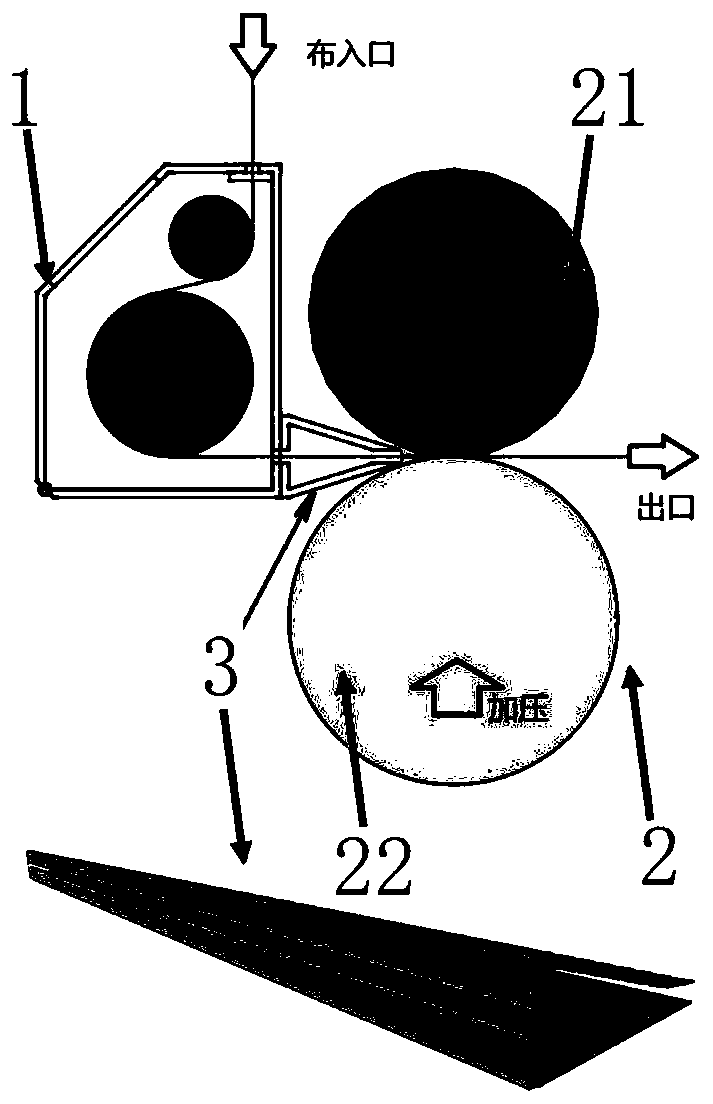

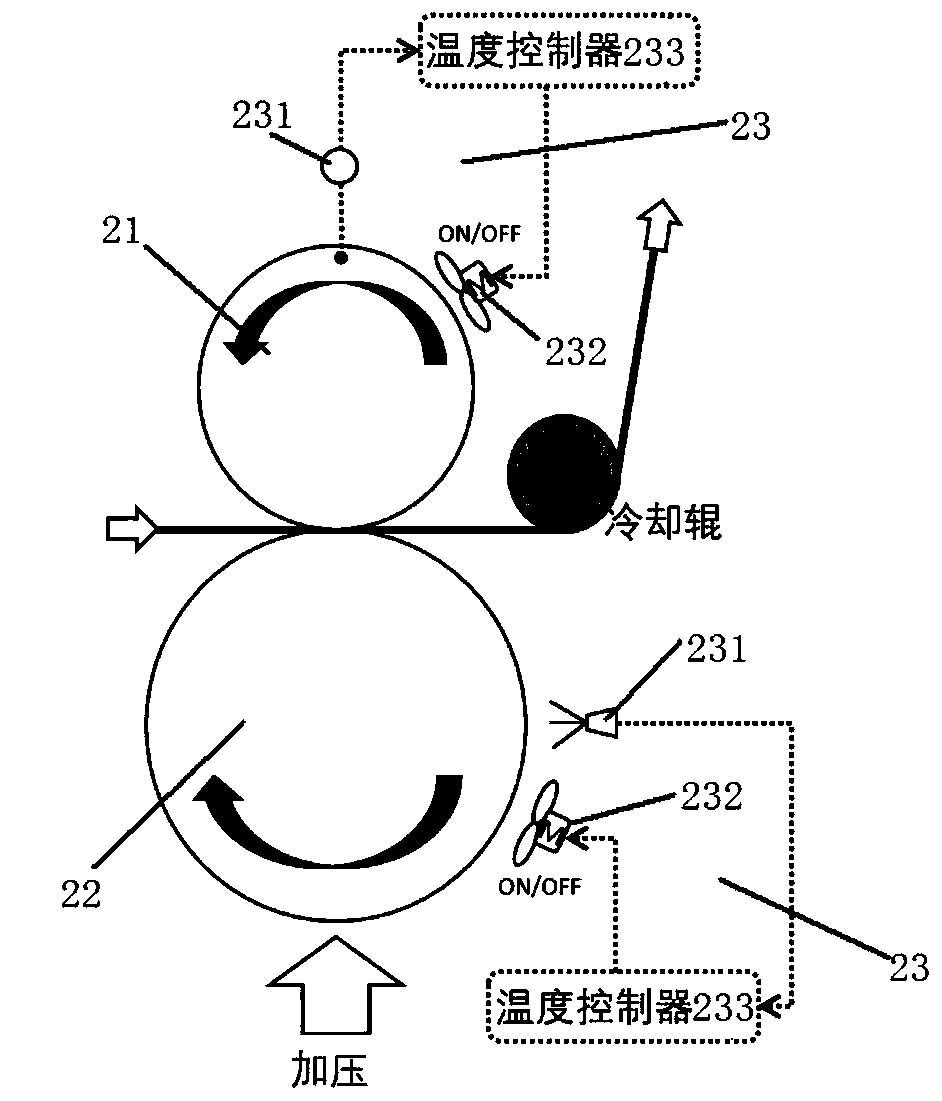

[0041] A heat-pressing separated calendering process for fabrics, comprising a heating system 1 and a nip system 2, the fabric passes through the heating system 1 and the nip system 2 in sequence for calendering, the heating speed of the heating system 1 is Synchronized with the nip speed of nip system 2, the fabric is heated before entering the nip.

[0042] A cloth surface temperature maintaining device 3 is also provided between the heating system 1 and the nip system 2, and the temperature of the fabric surface is maintained by the cloth surface temperature maintaining device 3; specifically, between the heating system 1 and the nip system 2, a cloth surface temperature maintaining device 3 is provided between 5cm-50cm to ensure that the heat loss is within 5°C.

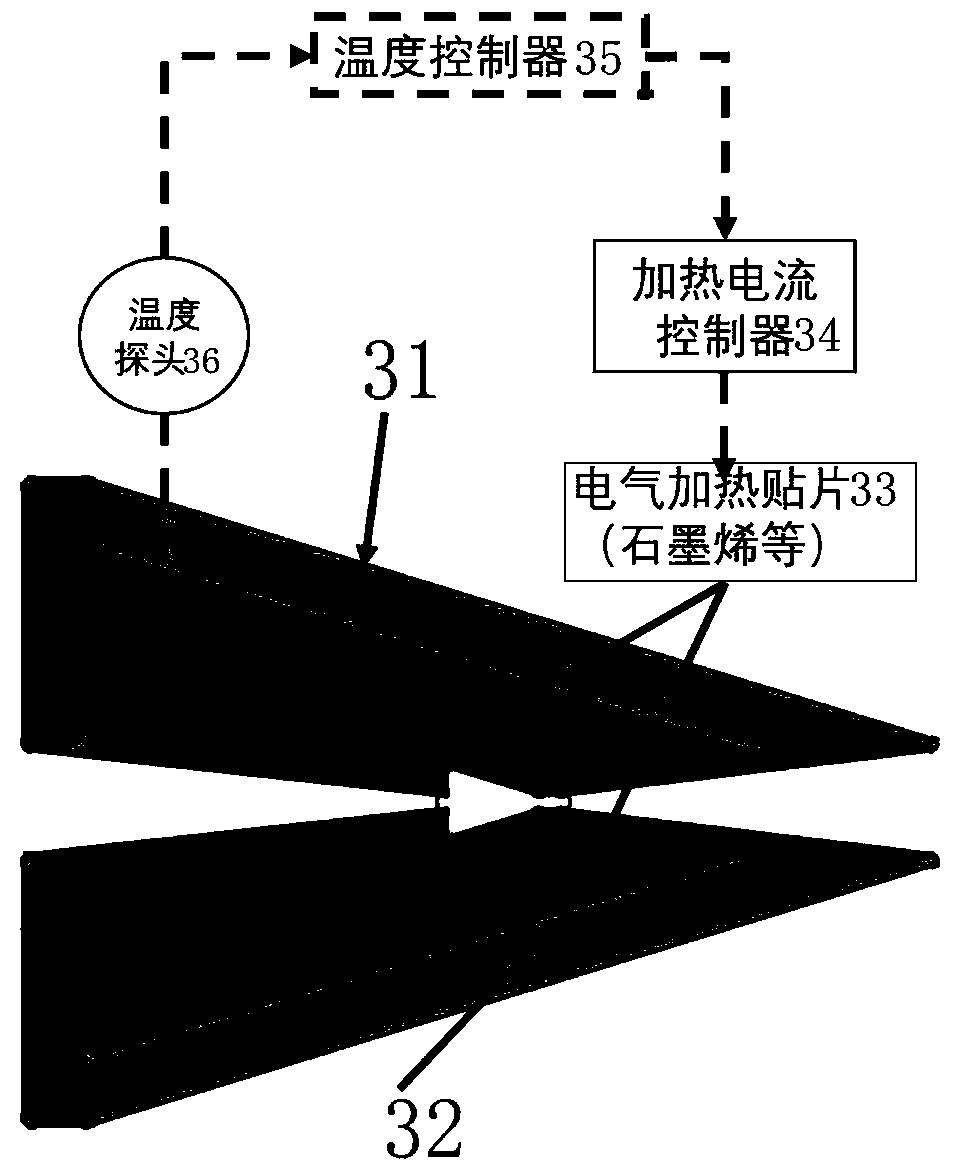

[0043] like Figure 1-2 As shown, the cloth surface temperature maintaining device 3 includes upper and lower two symmetrical metal shells 31 that can be spliced into a triangular shape, and the fabric passes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com