Patents

Literature

50results about How to "Improve color change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

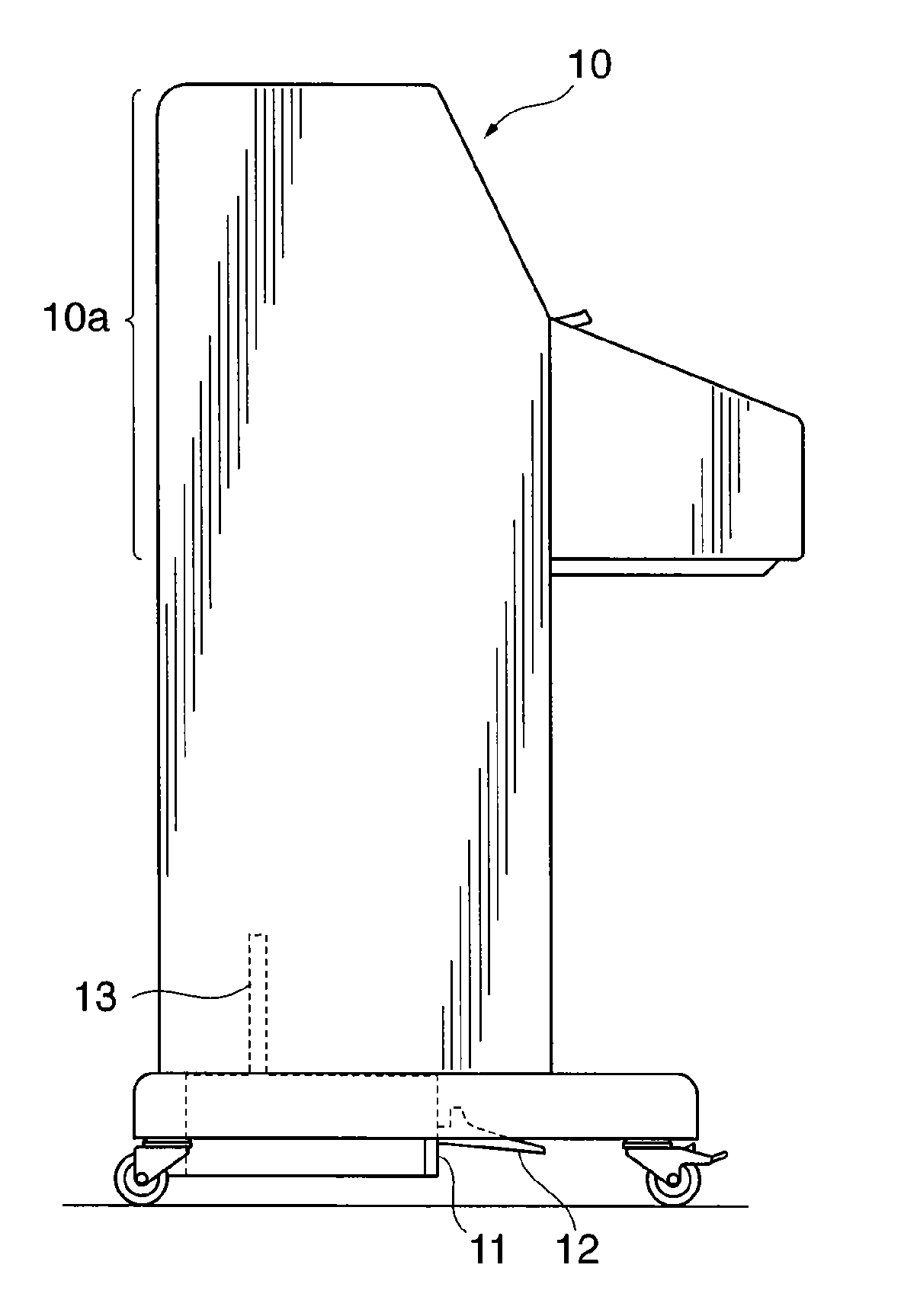

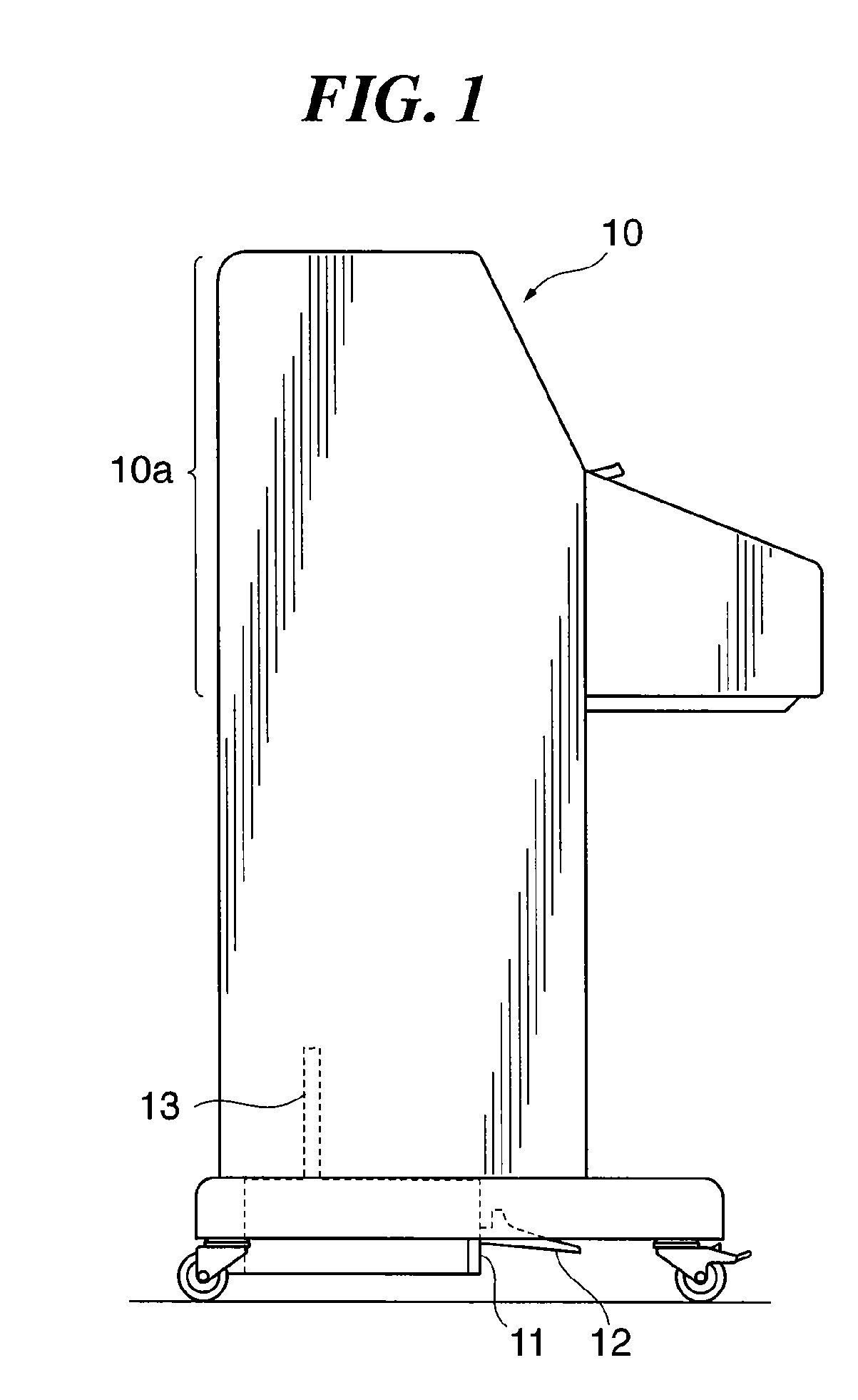

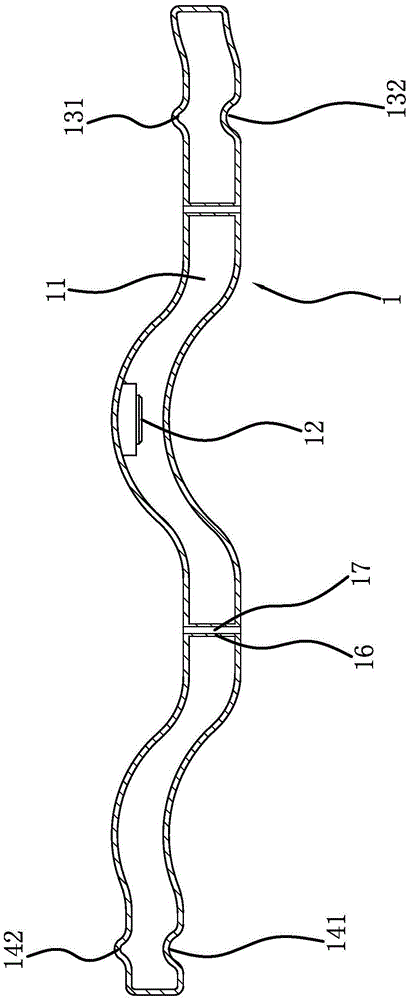

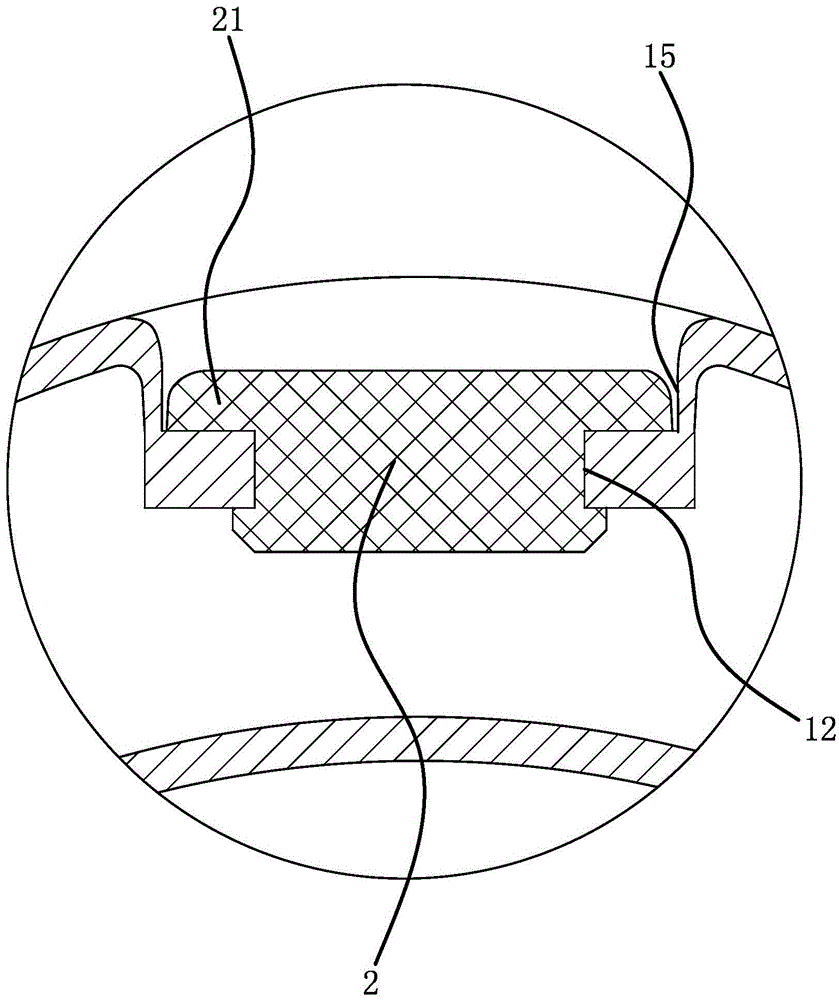

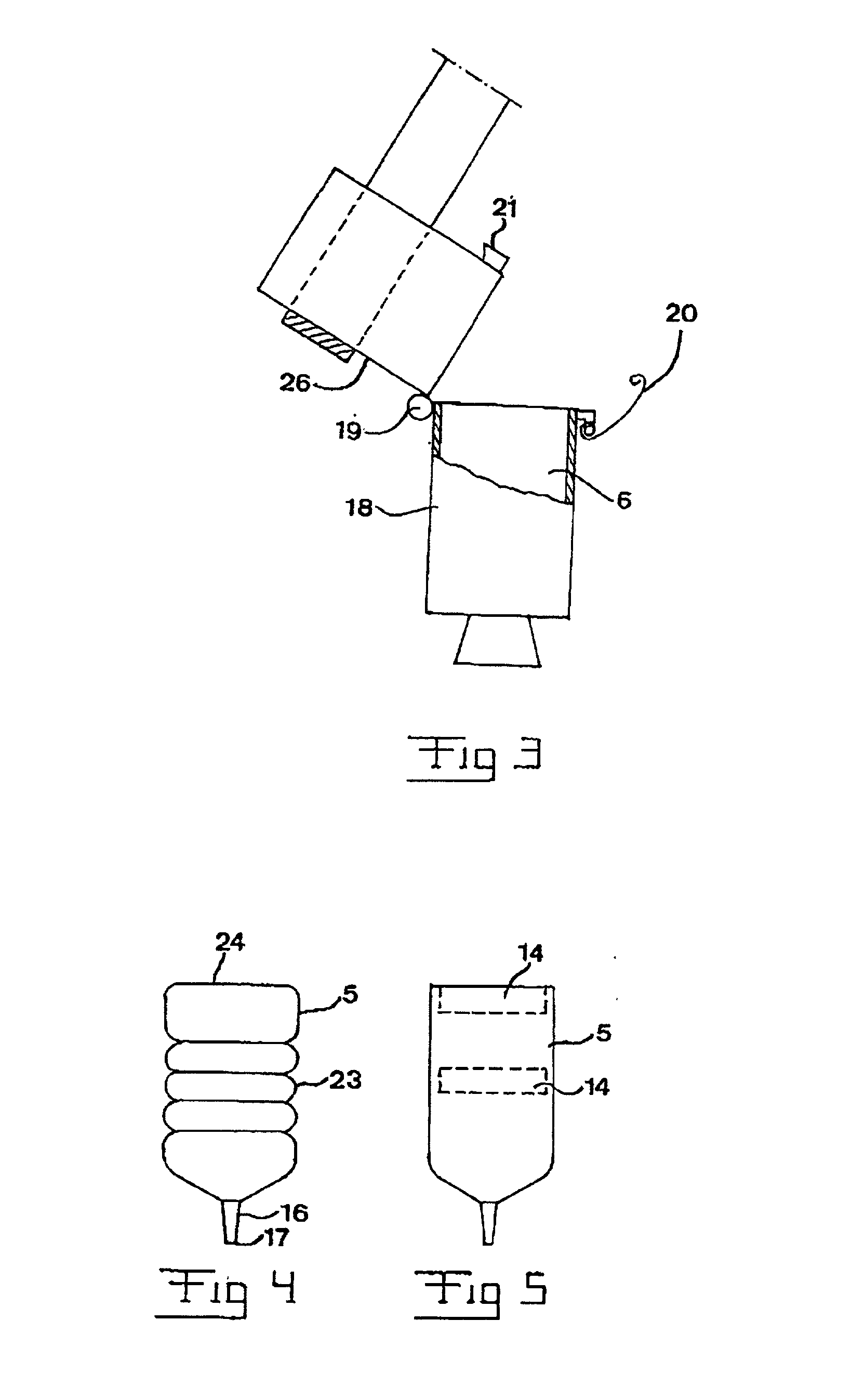

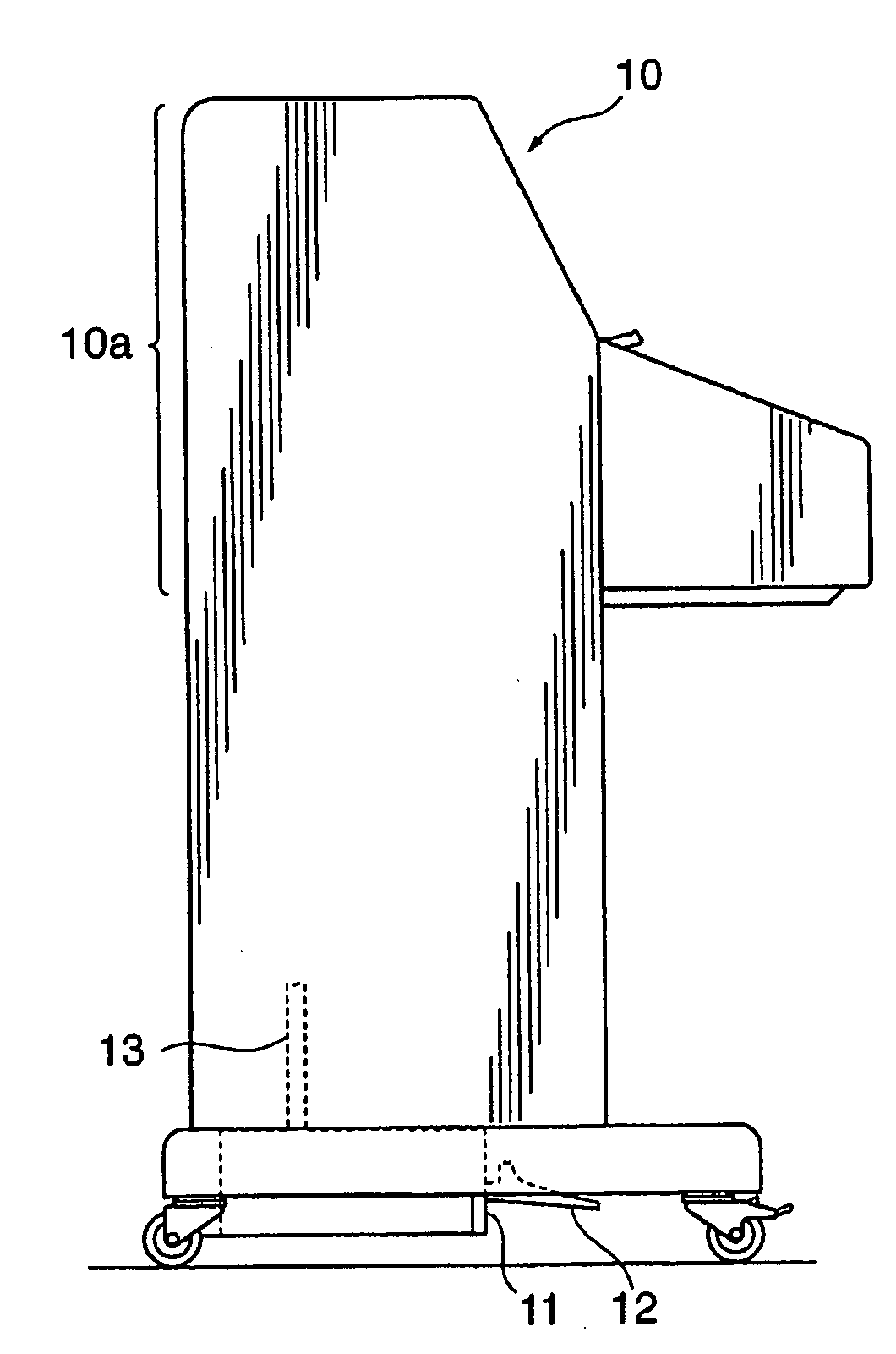

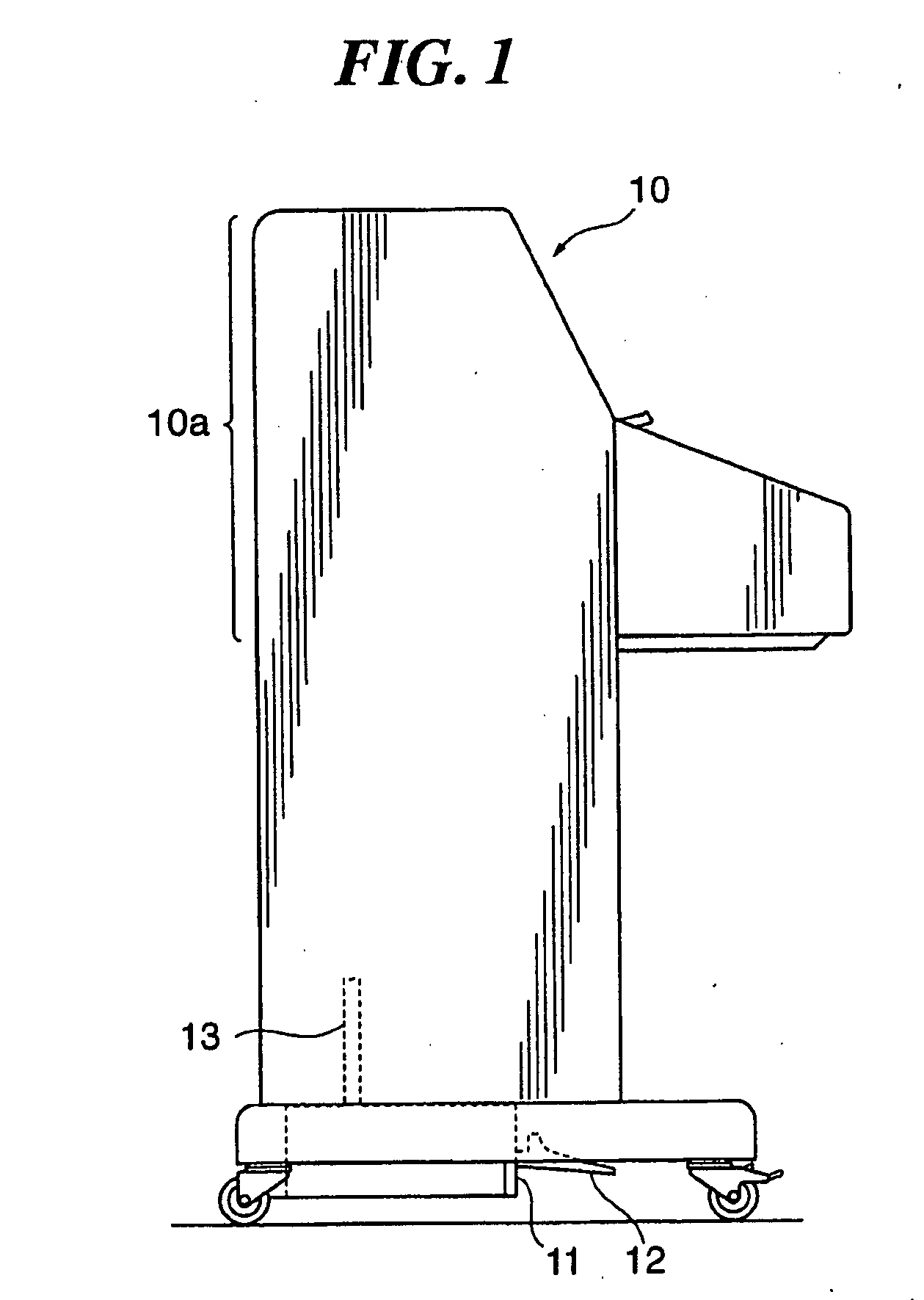

Tone plate for keyboard-type tone plate percussion instrument, tone plate fabricating method, tone generator unit of tone plate percussion instrument, and keyboard-type percussion instrument

ActiveUS7541530B2Increase freedomShorten the lengthStringed musical instrumentsPercussion musical instrumentsDegrees of freedomEngineering

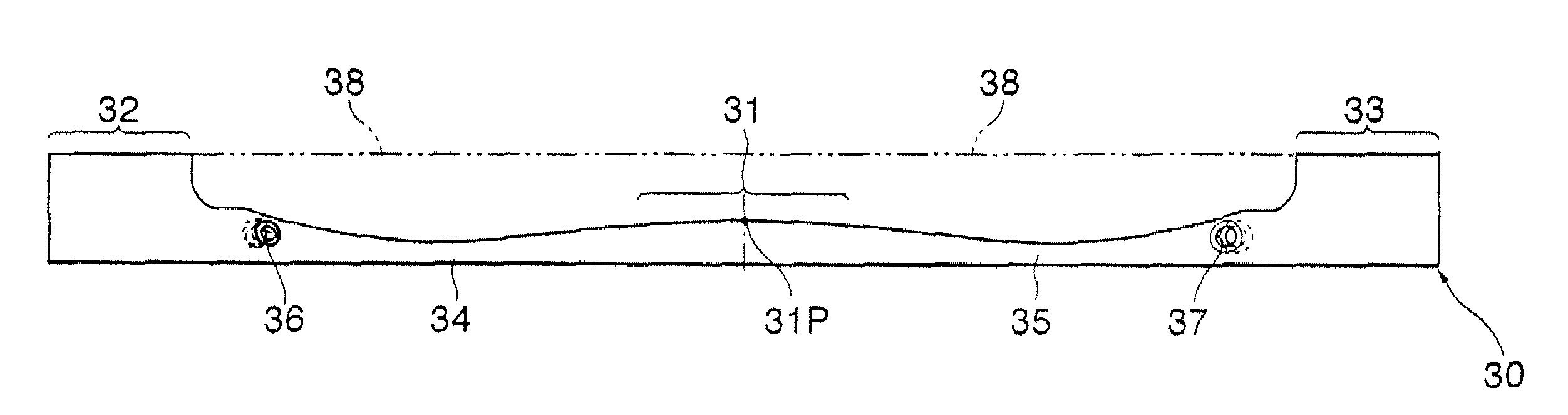

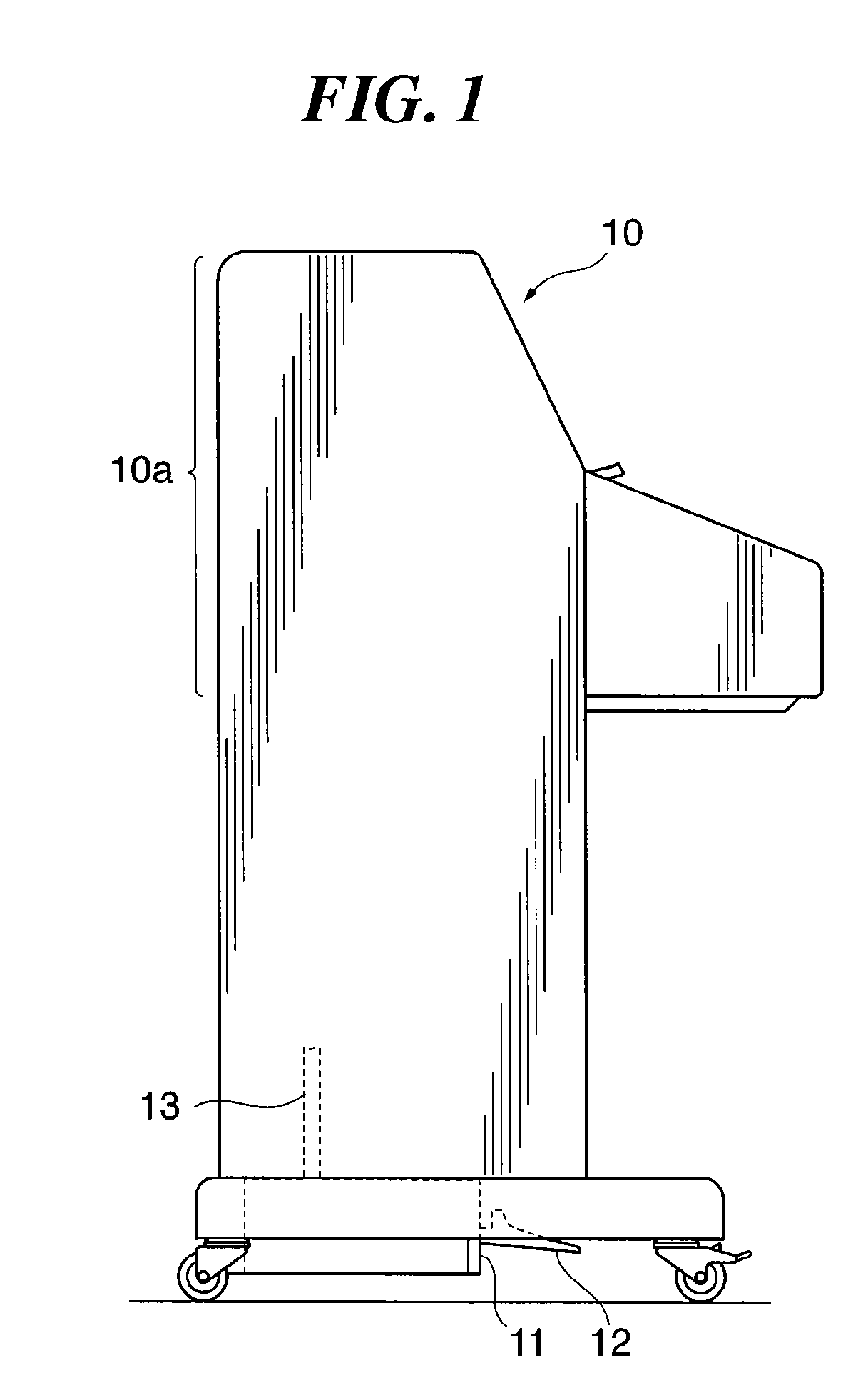

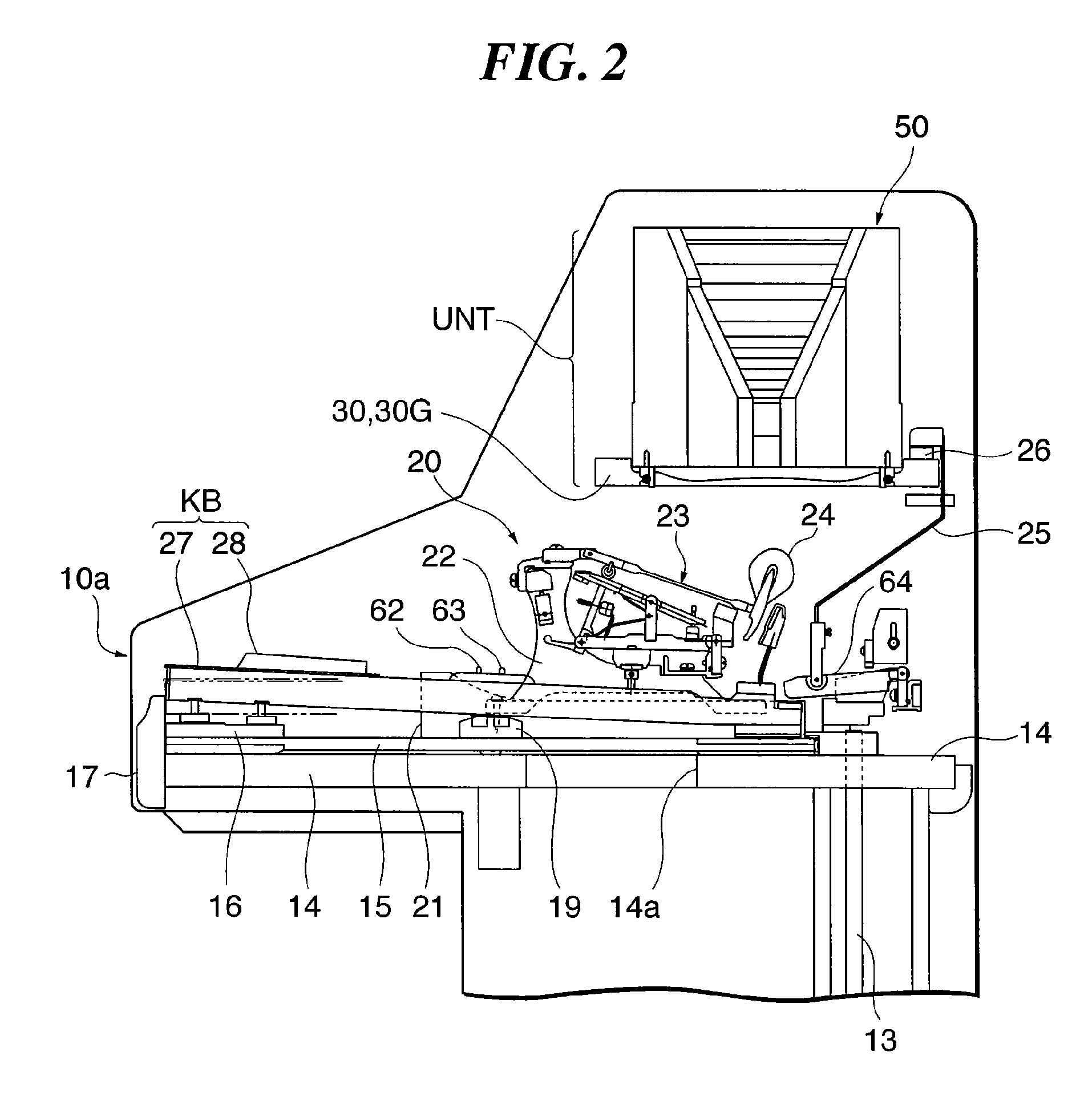

A tone plate which makes it easy to reduce the entire length and width thereof, thus increasing the degree of freedom in design. The tone plate includes an antinode portion, front and rear ends, and first and second supporting holes which are located closer to the front and rear ends than to the antinode portion and at which a vibration node can be formed. There are provided first and second mass concentrating portions extending toward the front and rear ends from locations on a side close to the first and rear ends with respect to the supporting holes. First and second thinner portions are respectively provided between the antinode portion and the supporting holes. The tone plate vibrates to generate a musical tone of a specific tone pitch when struck with being supported at the supporting holes.

Owner:YAMAHA CORP

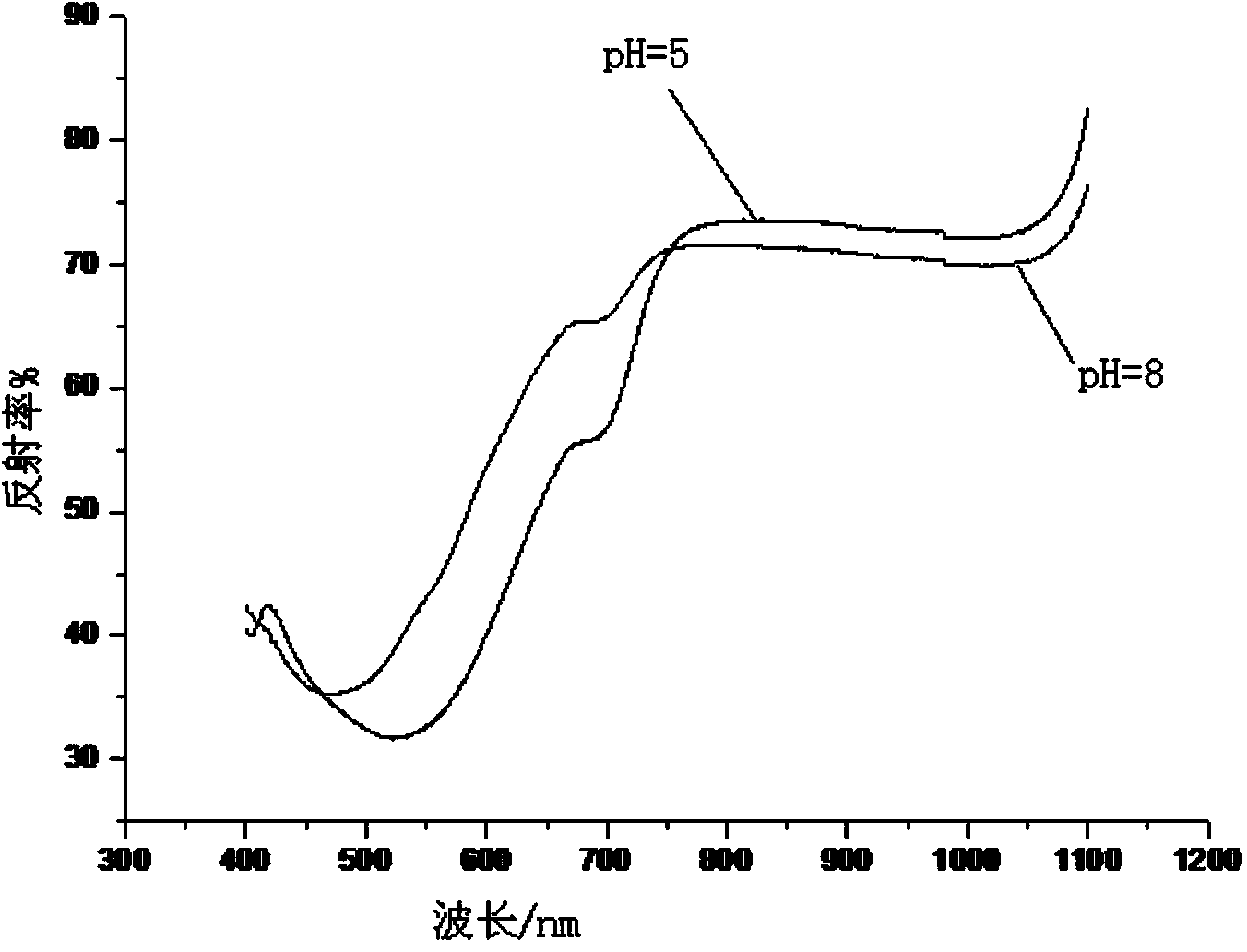

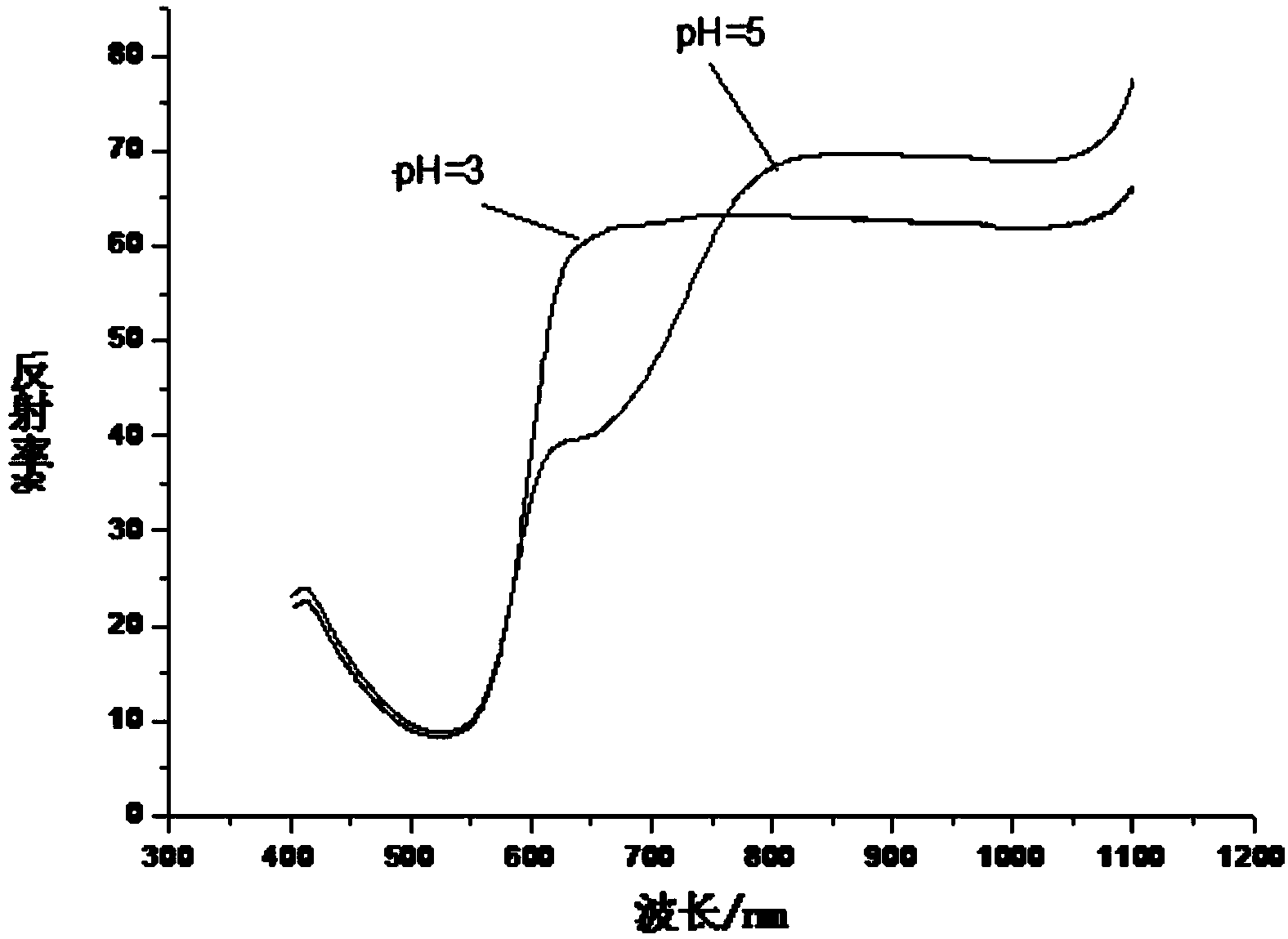

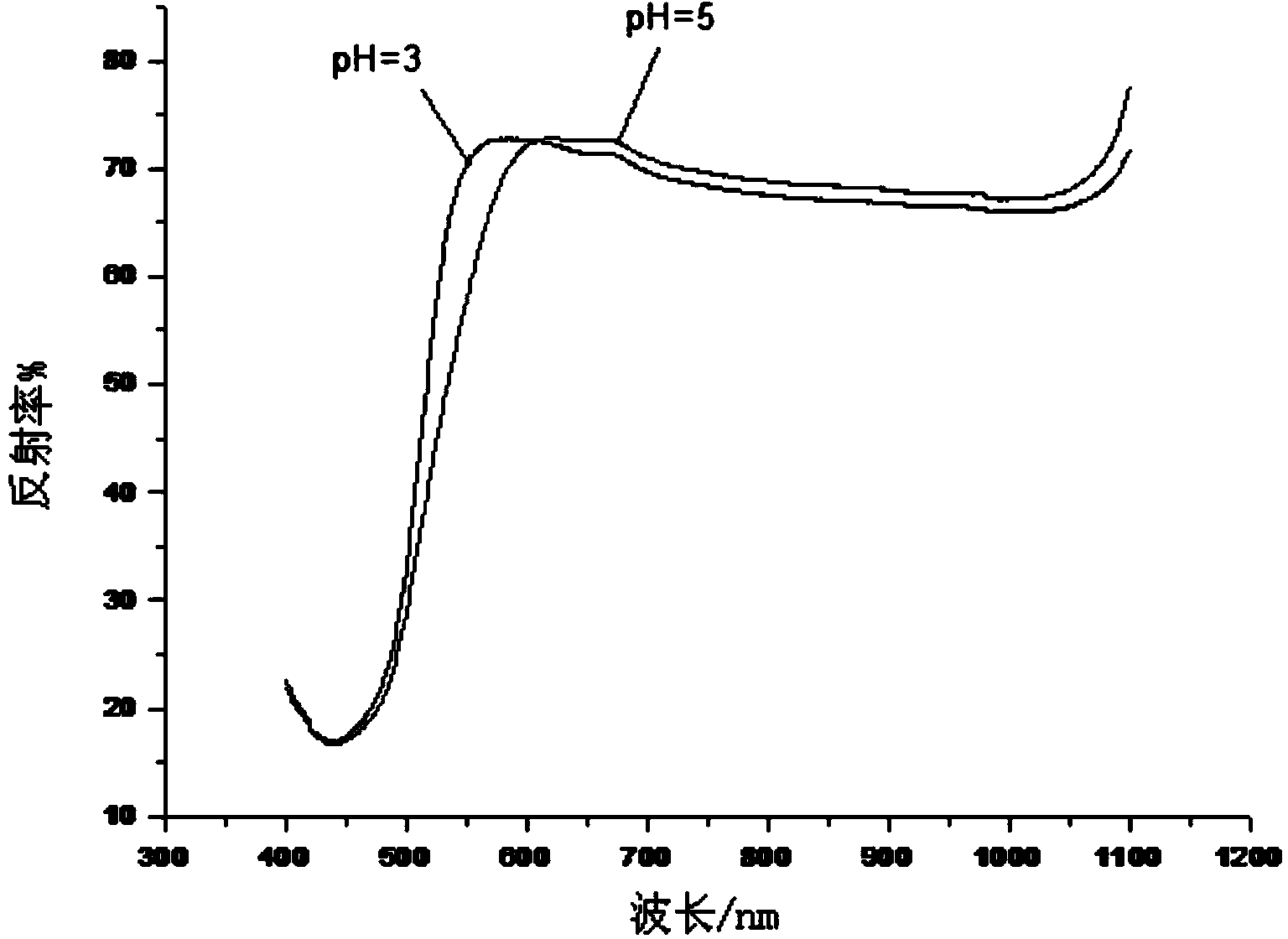

Preparation method of pH color-changing fabric

The invention relates to a preparation method of a pH color-changing fabric. The preparation method comprises steps as follows: (1), a dye solution is prepared by pH indicator dye and distilled water, then, a required amount of the dye solution is accurately measured and diluted, and a dye bath is obtained; (2), a bleached cotton fabric wetted in water is drained and then immersed in the dye bath for dyeing, a water bath constant-temperature oscillator is used for dyeing the dyeing cotton fabric, the fabric is dyed at 40 DEG C, the fabric is kept warm for 30 minutes after the temperature reaches 90 DEG C, then the cotton fabric is cooled to the normal temperature, the cotton fabric is washed in water, washed with soap and then dried after dyeing is finished, and the dyed cotton fabric is obtained; (3), the dyed cotton fabric is immersed into a pH buffer solution, and the pH color-changing fabric is obtained. According to the preparation method, the preparation process is simple and convenient, the cost is low, the wet color fastness and the crockfastness are good, the obtained pH color-changing fabric can be used for preparing a fabric pH sensor and the like, and the preparation method has a broad prospect.

Owner:DONGHUA UNIV

Colour development methyl aldehyde adsorption material and preparation method thereof

ActiveCN101468304AResponsivenessRapid pollutionMaterial analysis by observing effect on chemical indicatorOther chemical processesFormaldehyde productMethyl aldehyde

The invention discloses a chromogenic formaldehyde adsorbing material and a preparation method thereof. The adsorbing material consists of a carrier, a high molecular organic amine polymer, a polylol polymer and a formaldehyde reaction indicator, wherein the high molecular organic amine polymer and the polylol polymer account for 1 to 50 percent of formaldehyde adsorbent, the formaldehyde reaction indicator is little, and the balance being the carrier. The preparation method thereof comprises the following steps: mixing the high molecular organic amine polymer and the polylol polymer according to mass, adding deionized water to dilute the mixture so as to prepare formaldehyde reagent; mixing the formaldehyde reagent and the formaldehyde reaction indicator; and spraying or dipping the mixed solution onto the surface of the carrier, and drying the carrier and so on. The adsorbing material and the preparation method can quickly, thoroughly and continuously remove formaldehyde pollution in indoor air until the content of the formaldehyde is reduced to safe concentration, are nontoxic, pollution-free, safe and environment-friendly to use, and can intuitively show the reaction degree of the formaldehyde.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

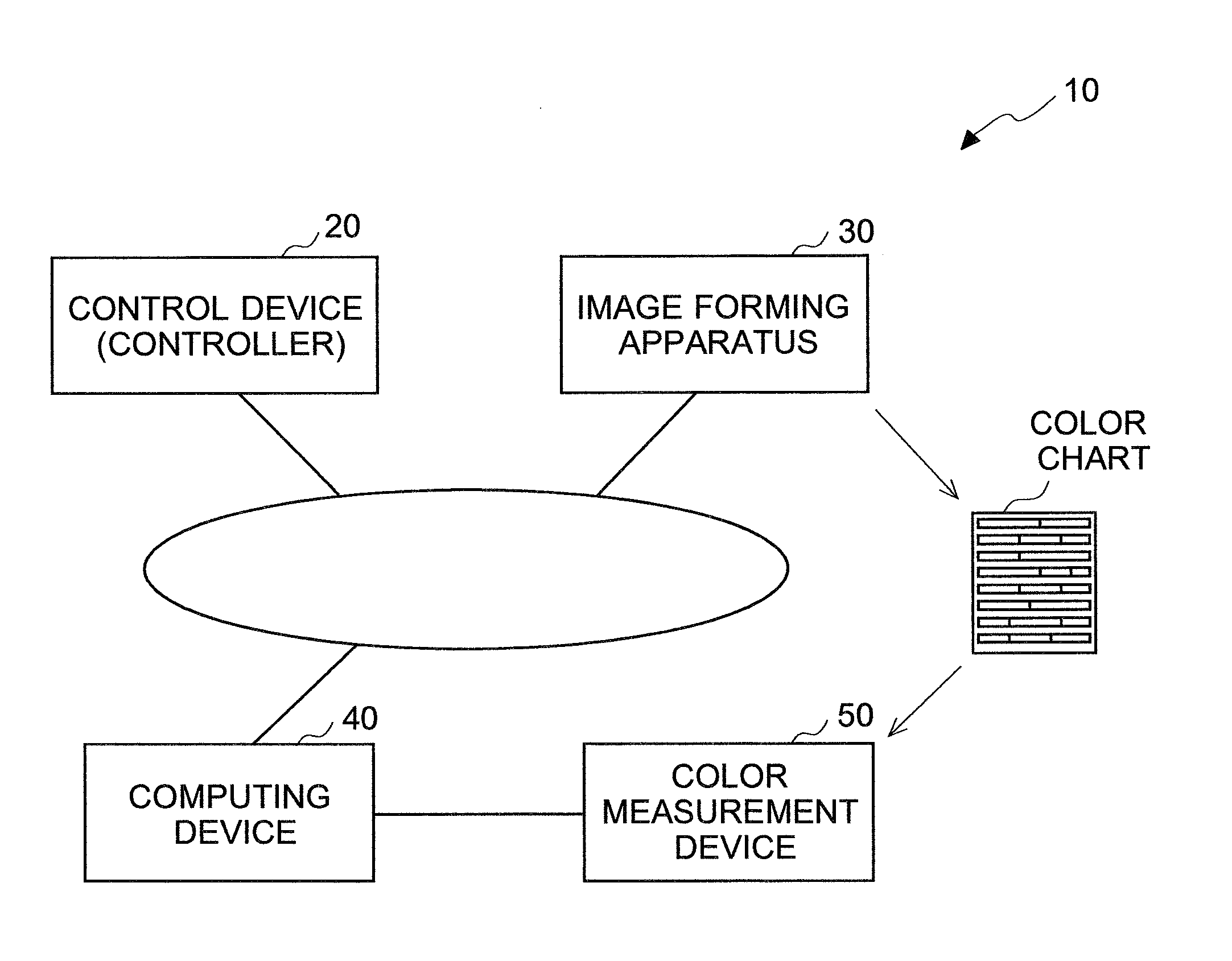

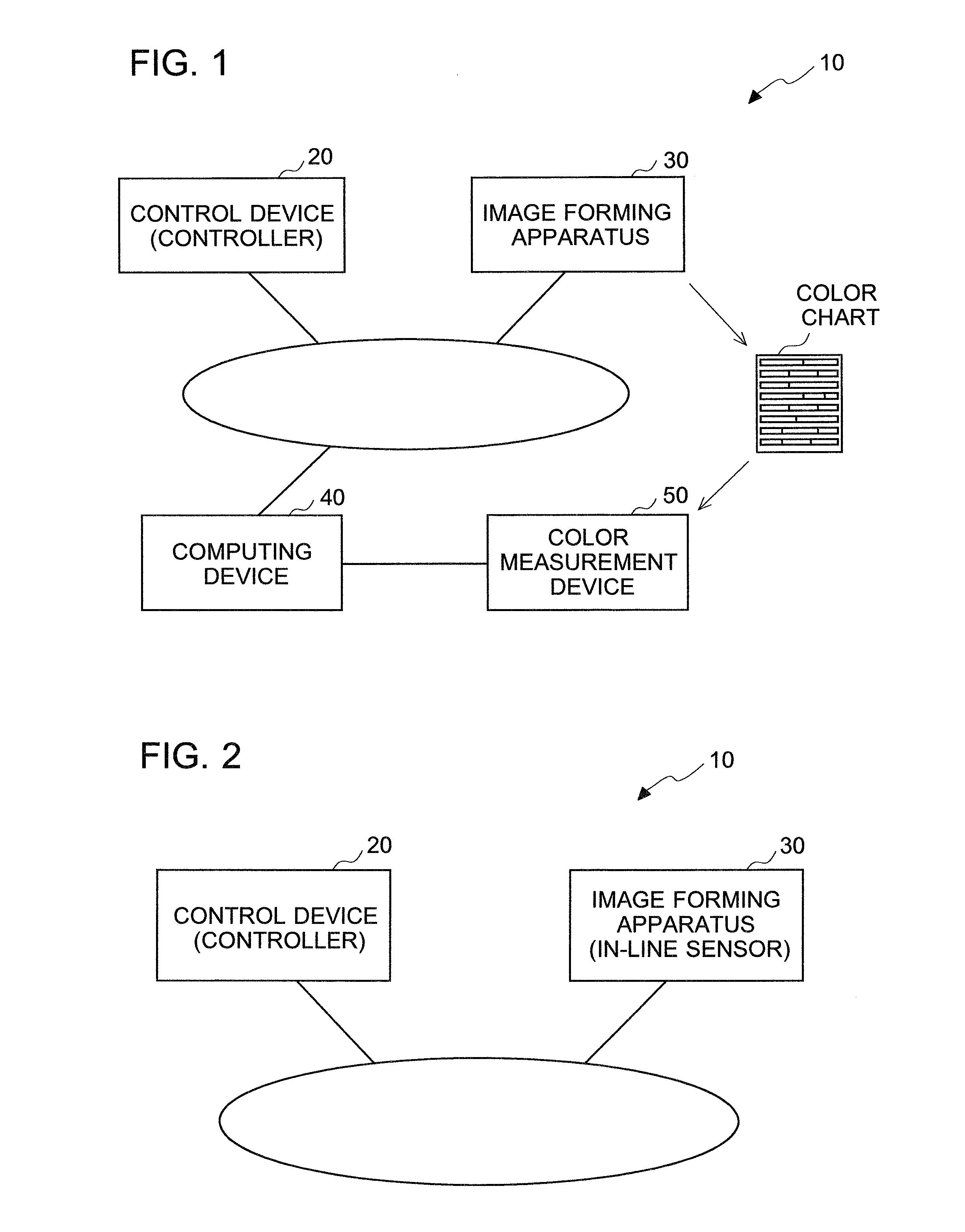

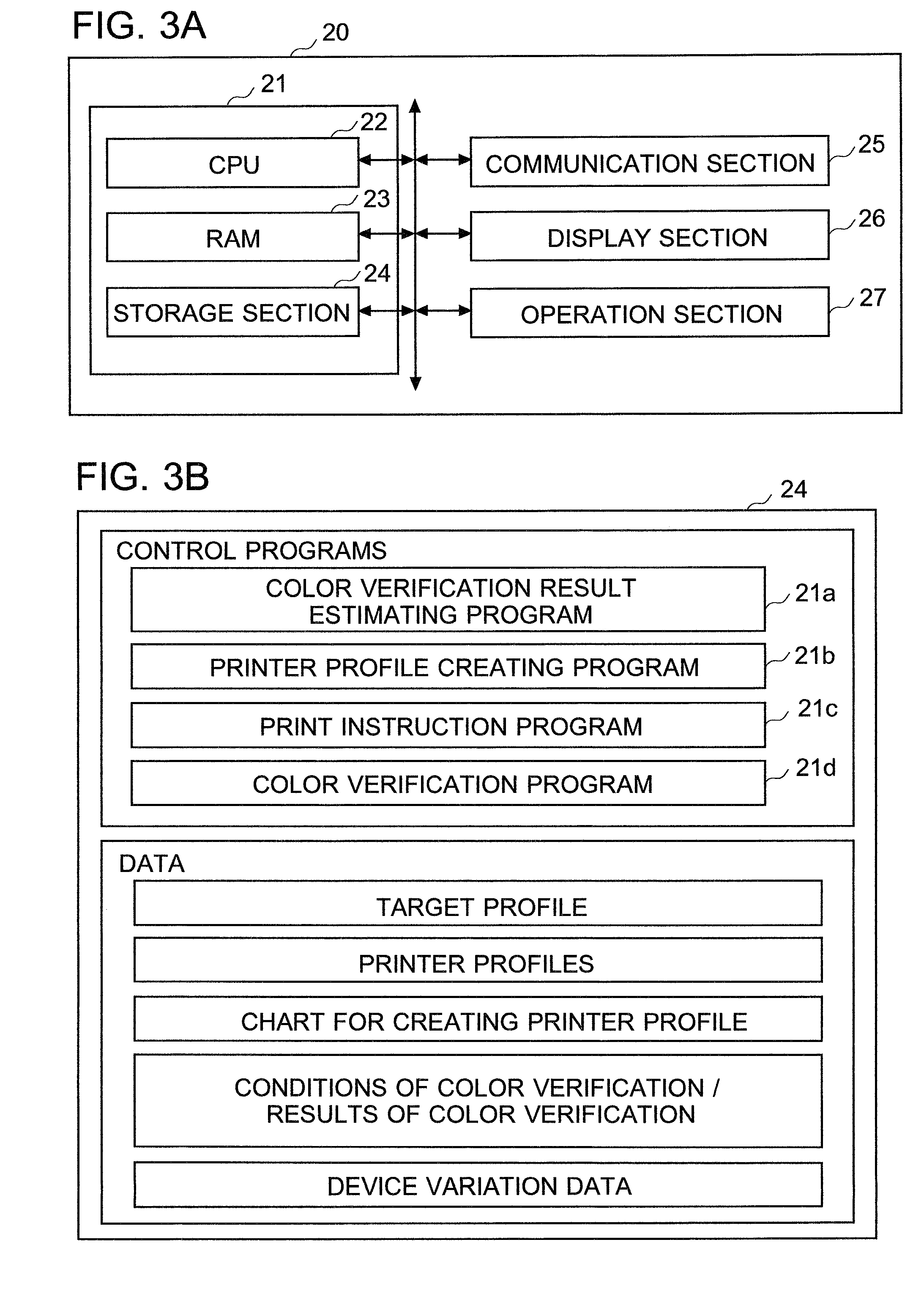

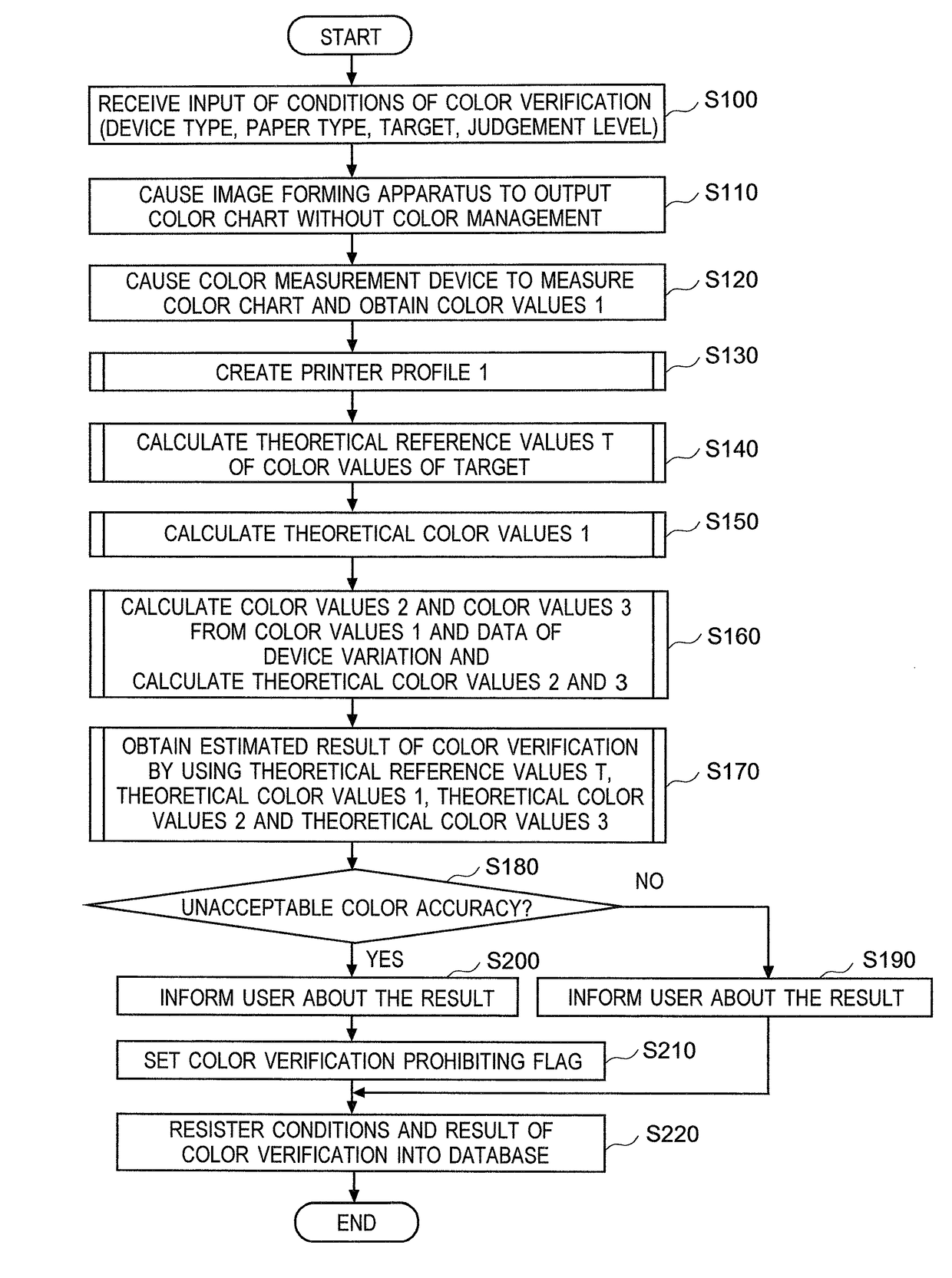

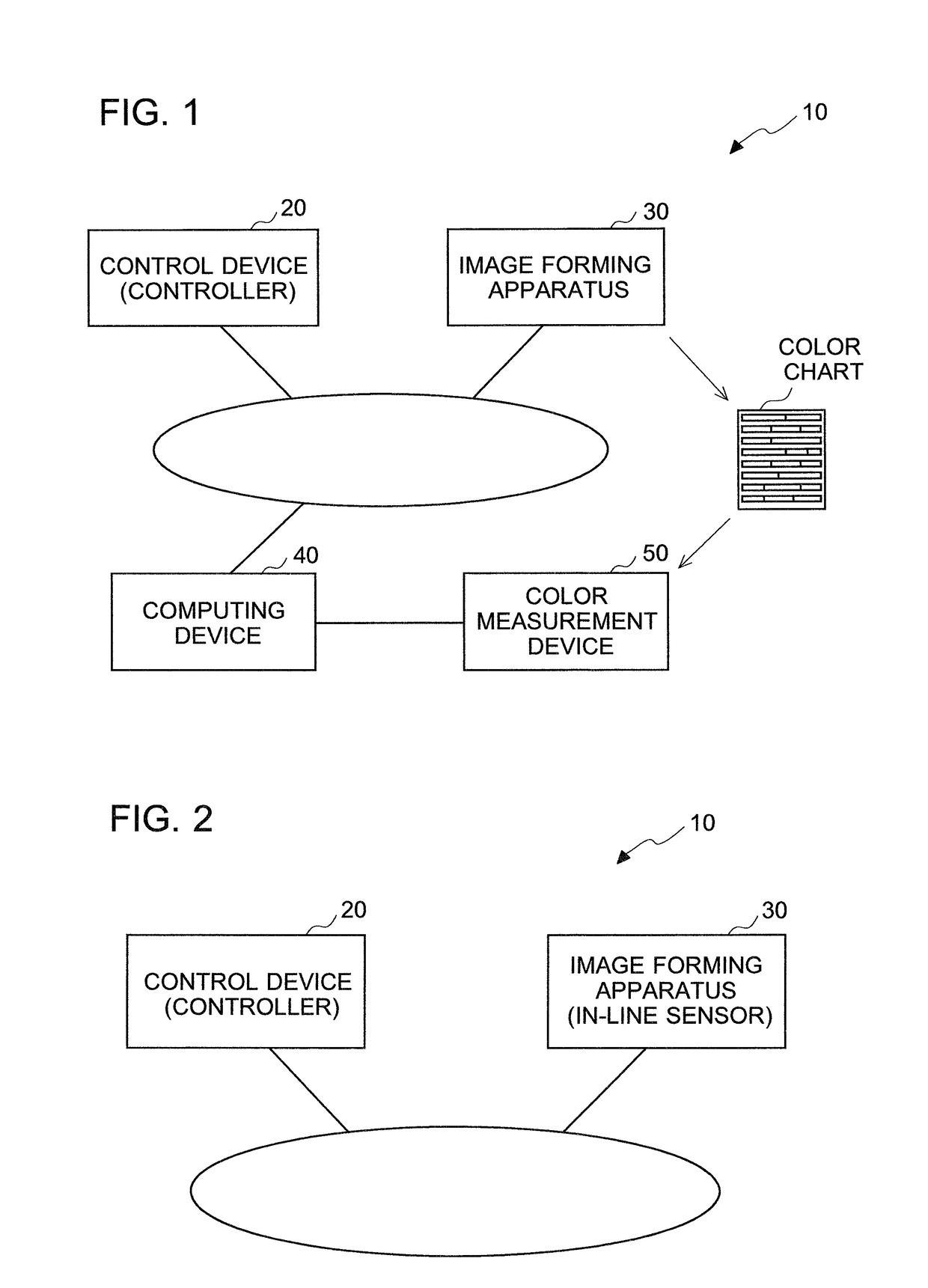

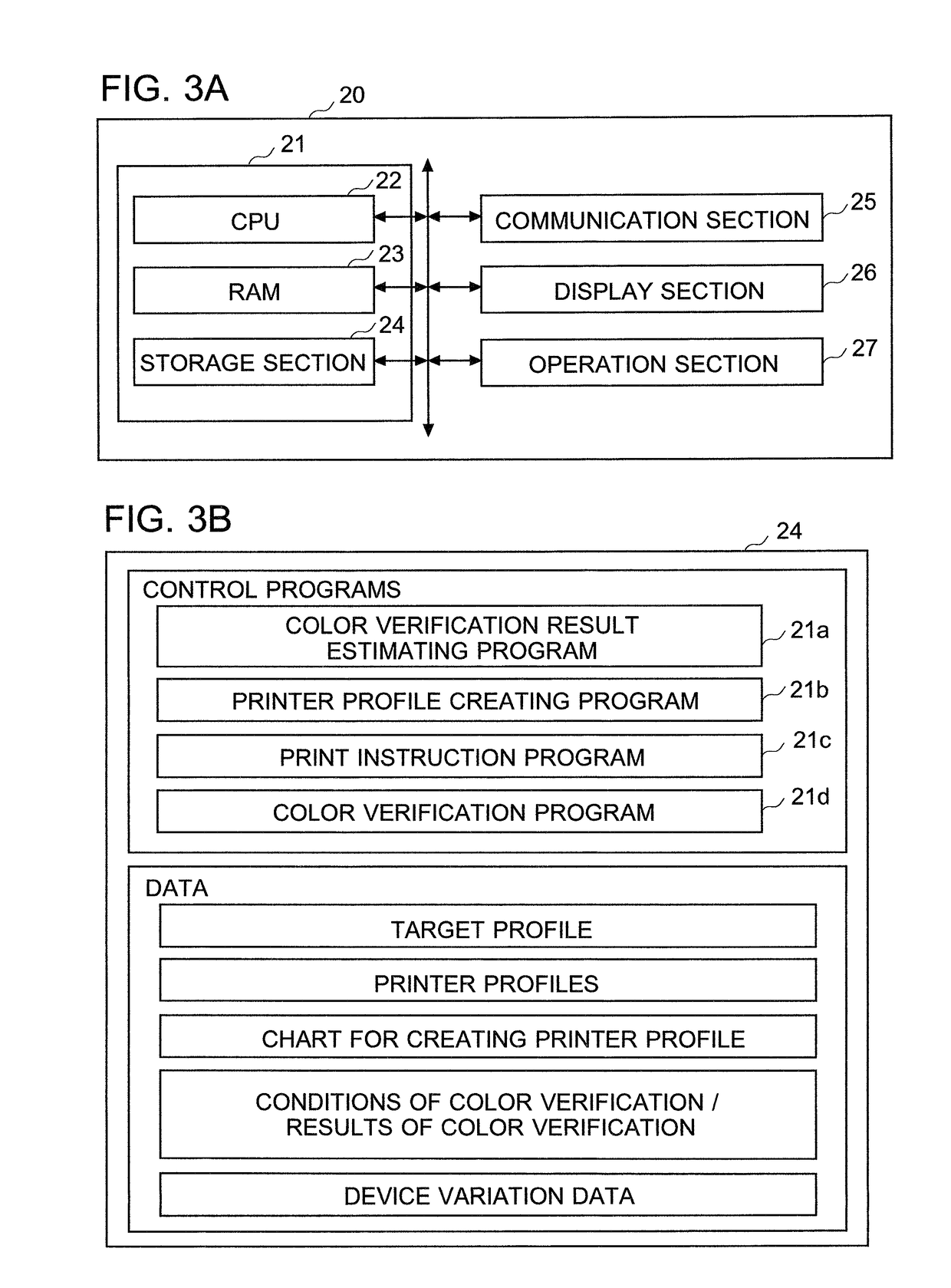

Method, control device and non-transitory computer-readable storage medium storing program for estimating color verification result

ActiveUS20160239728A1Improve color changeEasy detectionVisual presentation using printersInput/output processes for data processingColor differenceControl equipment

A control device estimates a color verification result by using the following method. The method includes obtaining a first set of color values by using measurements of a color chart printed by a printer without color management; calculating second and third sets of color values based on increased color gamut and reduced color gamut of the printer due to a conditional change of the printer; creating a first to third printer-profiles by using the first to third sets of color values; calculating theoretical reference values of target color values and first to third theoretical color values by using the first to third printer-profiles; calculating first to third color differences by using the theoretical reference values and the first to third theoretical color values; obtaining an estimated result of the color verification by comparing the first to third color differences with a preset standard value; and outputting the estimated result.

Owner:KONICA MINOLTA INC

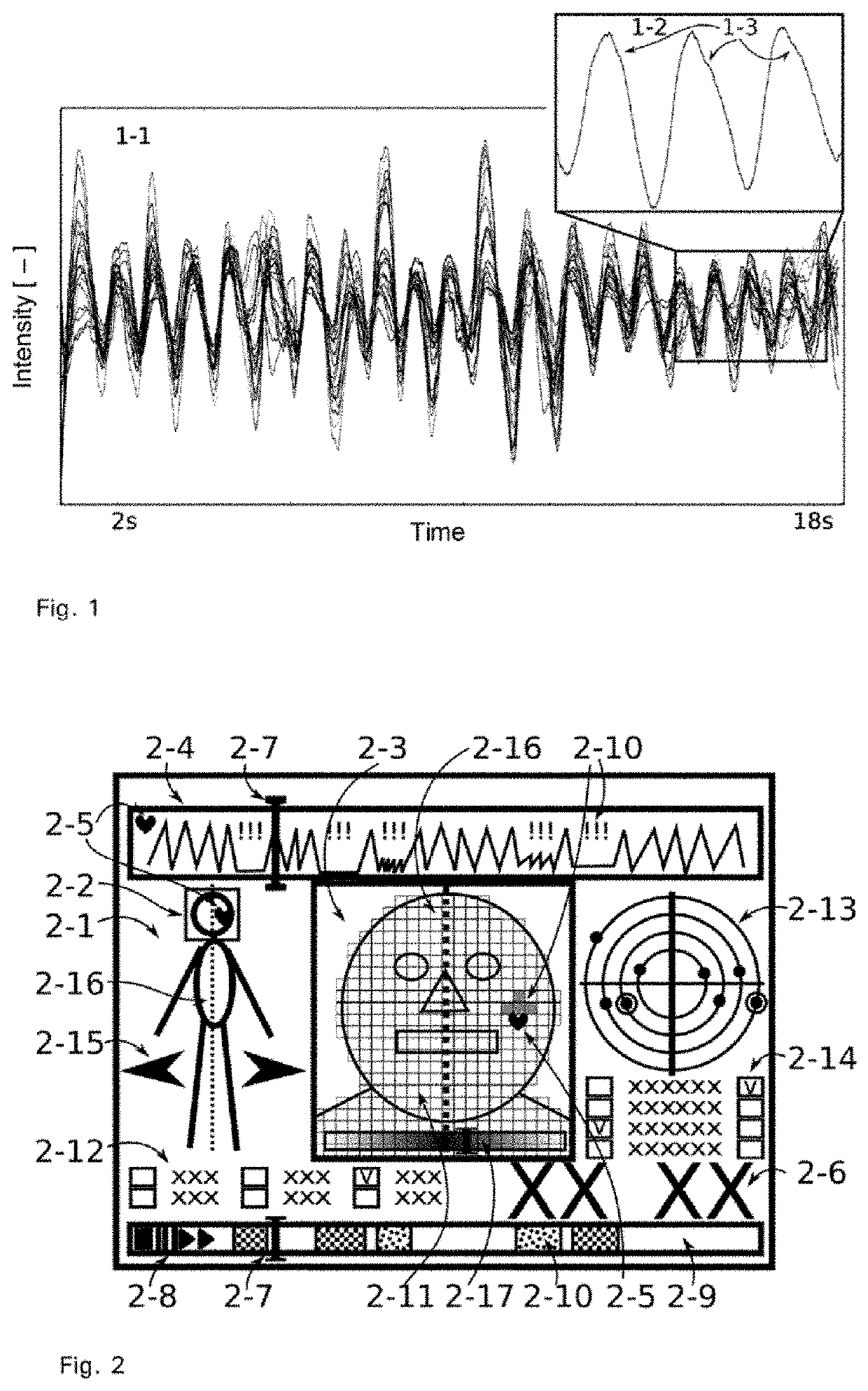

Device and method for recording and analysing images of the skin

PendingUS20210068670A1Cutting can not be obtainedData augmentationImage enhancementImage analysisBiological bodyHeart beat rate

The invention relates to a device and a method for the contact-free analysis of changes to skin color in living organisms, in particular in humans. Images of a skin region to be examined are recorded by means of one or more cameras and are then analyzed, in digital form, by a computer unit. In particular, one or more colors or one or more spectral ranges can be identified in a temporal sequence of occurring intensity changes, and on this basis inferences can be made regarding vital functions, in particular heart rate, pulse wave and the temporal and spatial profile thereof. Data can be derived on this basis which can be used to determine the state of health of the examined individual.

Owner:REDTEL HEIKO

Special color heat-pressing label for resin grinding wheel

The invention discloses a special colored hot-press label of a resin grinding wheel. The special colored hot-press label comprises a black paperboard or a copper printing paper substrate, a bottom layer, a pattered oil layer and a protective layer, wherein the bottom layer, the pattered ink layer and the protective layer are offset-printed on the substrate. Aiming at realizing small color change amplitude after a finished product label and the grinding wheel are sintered and vulcanized together, ink for the pattered ink layer is scientifically prepared from materials, such as polydimethylsiloxane phenolic resin, a chemical corrosion resisting agent, an anti-friction agent, tung oil, organic pigment, and the like, crude ink is modified, the high-temperature softening point of the ink layeris improved, the adhesive film hardness of the surface of the ink layer is increased, and an adhesive film gap on the surface of the ink layer is sealed. The special colored hot-press label has the advantages that: a brand name and various technical data of the grinding wheel are printed with various colors of ink by utilizing the appropriate substrate and then die-cut and formed, and directly hot-pressed on the surface of the substrate in the production process of the grinding wheel, and the grinding wheel is discharged from a furnace after dried in a high-temperature vulcanizing kiln for 30h at 186 DEG C, therefore, the mark of the label is very distinct, not powdered and obscure, and the color change amplitude is less than 10 percent.

Owner:郑州市晶森彩印有限公司

Tone plate for keyboard-type tone plate percussion instrument, tone plate fabricating method, tone generator unit of tone plate percussion instrument, and keyboard-type percussion instrument

ActiveUS20070131092A1Easy reduce entire lengthEasy widthStringed musical instrumentsPercussion musical instrumentsDegrees of freedomFront and back ends

A tone plate which makes it easy to reduce the entire length and width thereof, thus increasing the degree of freedom in design. The tone plate includes an antinode portion, front and rear ends, and first and second supporting holes which are located closer to the front and rear ends than to the antinode portion and at which a vibration node can be formed. There are provided first and second mass concentrating portions extending toward the front and rear ends from locations on a side close to the first and rear ends with respect to the supporting holes. First and second thinner portions are respectively provided between the antinode portion and the supporting holes. The tone plate vibrates to generate a musical tone of a specific tone pitch when struck with being supported at the supporting holes.

Owner:YAMAHA CORP

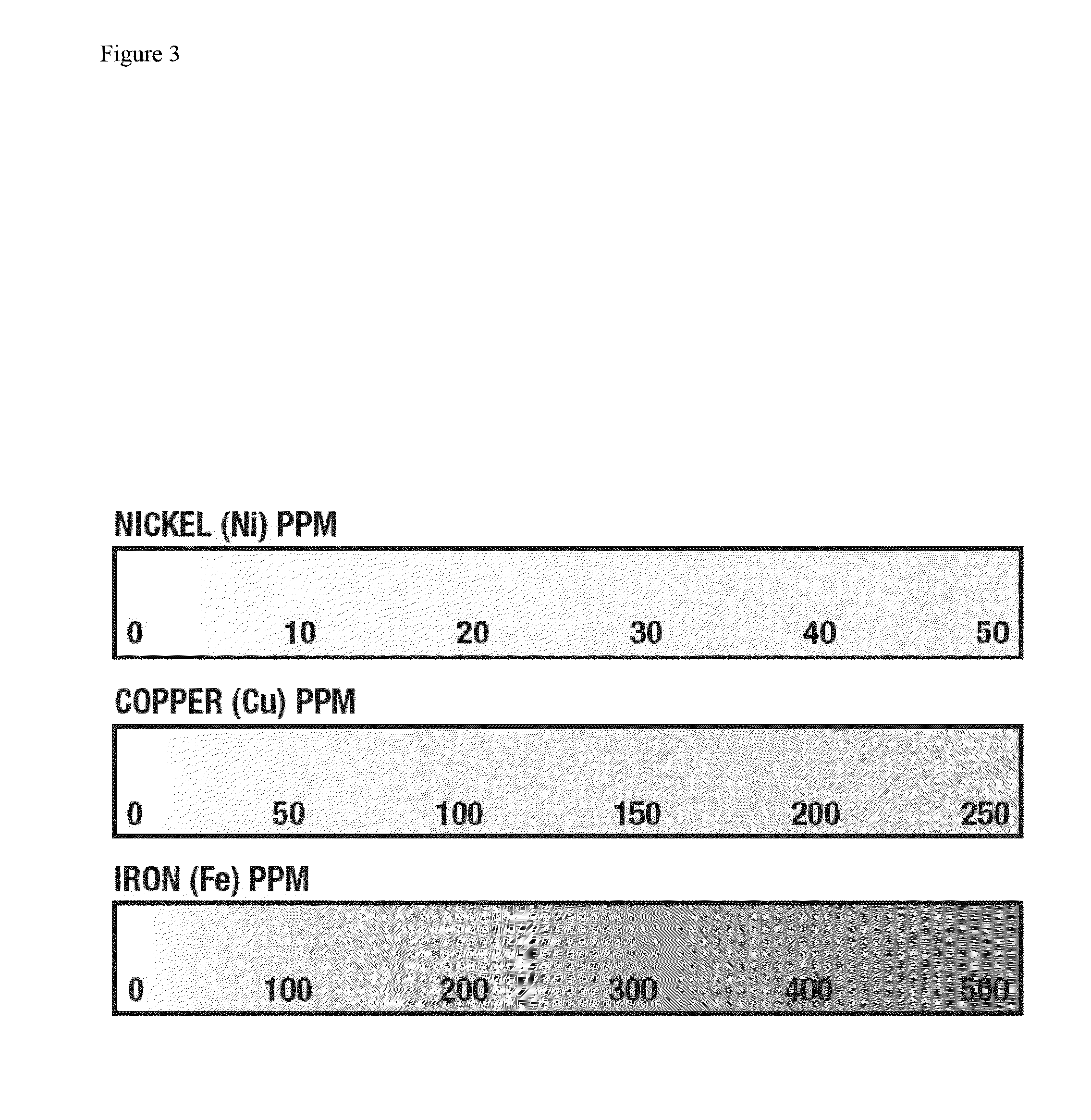

Methods and kits for analyzing automotive fluids

InactiveUS20160018336A1Perform very rapidlyAddressing slow performanceAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorChemical substanceEngineering

The invention provides kits and methods for assessing an automotive fluid and for determining if or when an automotive fluid should be or is in need of being replaced. The kit contains a test medium that may be a paper separated into two or more distinct, separable sections or compartments containing thereon an effective amount of at least one chemical or substance that effect or facilitate a color change in the presence of one or more substance, metal or impurity such as, for instance, iron, copper, or nickel. The test medium may be arranged in a substantially cubical form and contain multiple layers of test medium.

Owner:SCHORNSTEIN RONALD

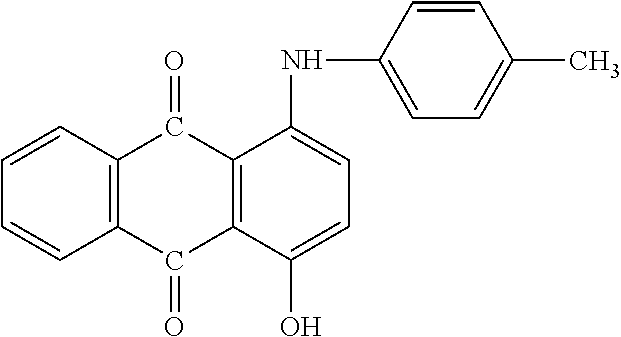

Spectacle lens

ActiveUS20100029812A1High light transmittanceImprove heat resistancePlastic/resin/waxes insulatorsOptical elementsHeat resistanceEyewear

A resin composition which contains polycarbonate resin, does not transmit a wavelength of 385 nm substantially and has a high total light transmittance and excellent heat resistance.The resin composition comprises (1) polycarbonate resin, (2) an ultraviolet absorber (A) such as 2-(2H-benzotriazol-2-yl)-p-cresol, (3) an ultraviolet absorber (B) such as 2,2′-methylenebis[4-(1,1,3,3-tetramethylbutyl)-6-(2H-benzotriazol-2-yl)phenol] and (4) at least one compound (C) represented by the following formula (I) or (II) and is used for spectacle lenses.(R1—S—CH2—CH2—C(O)O—CH2—)4C (I)(R2—O—C(O)—CH2—CH2—)2S (II)(wherein R1 is an alkyl group having 4 to 20 carbon atoms, and R2 is an alkyl group having 6 to 22 carbon atoms.)

Owner:TEIJIN KASEK KK

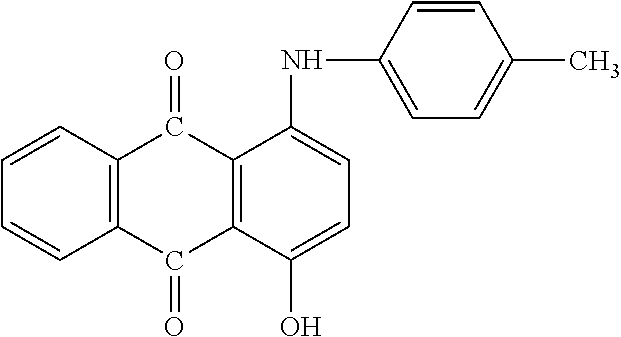

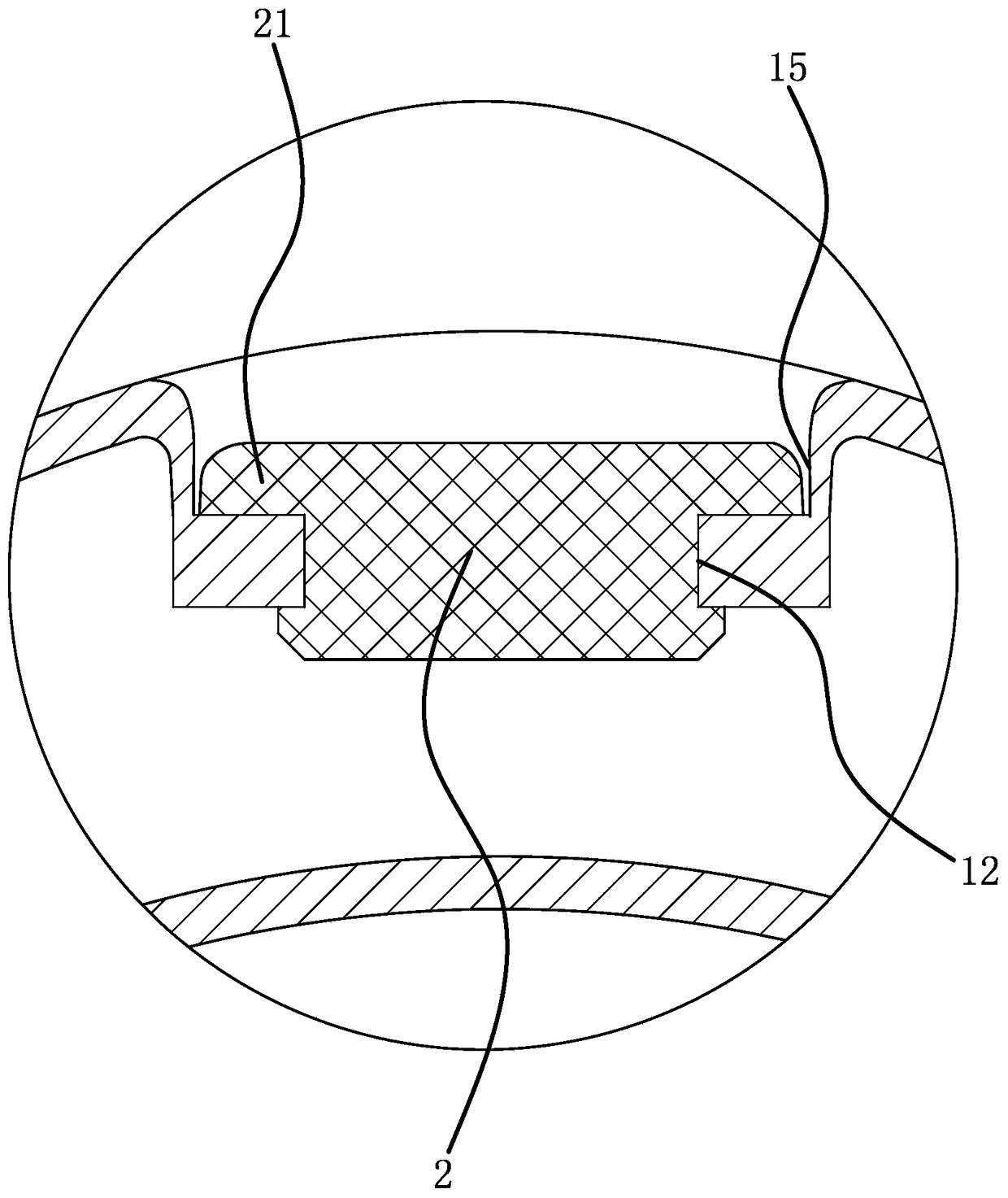

Light emission device

ActiveUS20080217630A1Improve fitImprove color changeSolid-state devicesSemiconductor devicesSemiconductor chipLight emitting device

The invention relates to a light emission device, comprising at least two light-emitting semiconductor chips and a substrate. At least one first semiconductor chip (12) is fitted on the substrate and a second semiconductor chip (14) is fitted on the first semiconductor chip (12).

Owner:IVOCLAR VIVADENT AG

Method, control device and non-transitory computer-readable storage medium storing program for estimating color verification result

ActiveUS9684856B2Improve color changeEasy detectionVisual presentation using printersPictoral communicationPattern recognitionGamut

A control device estimates a color verification result by using the following method. The method includes obtaining a first set of color values by using measurements of a color chart printed by a printer without color management; calculating second and third sets of color values based on increased color gamut and reduced color gamut of the printer due to a conditional change of the printer; creating a first to third printer-profiles by using the first to third sets of color values; calculating theoretical reference values of target color values and first to third theoretical color values by using the first to third printer-profiles; calculating first to third color differences by using the theoretical reference values and the first to third theoretical color values; obtaining an estimated result of the color verification by comparing the first to third color differences with a preset standard value; and outputting the estimated result.

Owner:KONICA MINOLTA INC

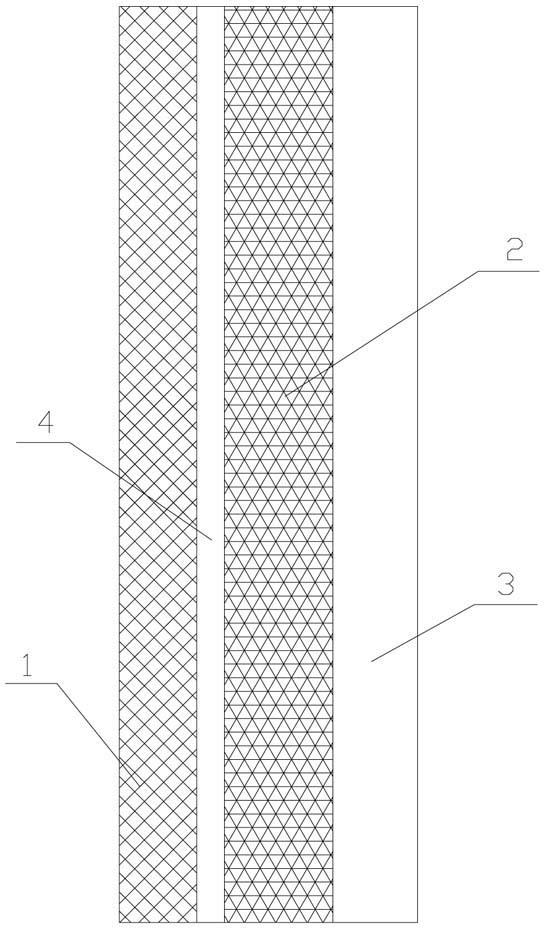

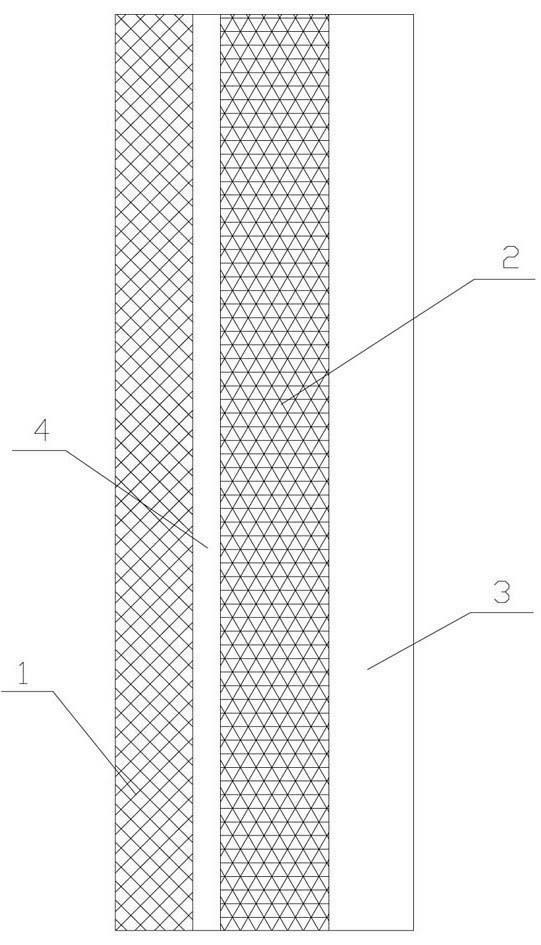

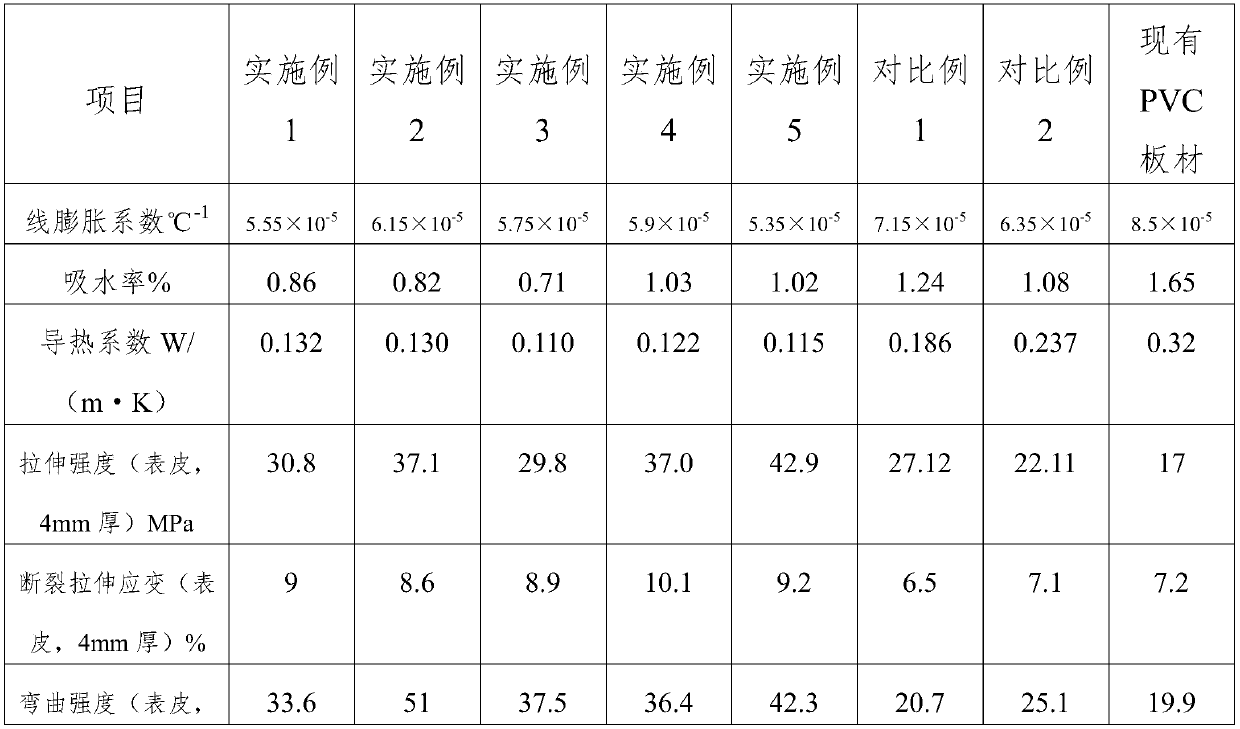

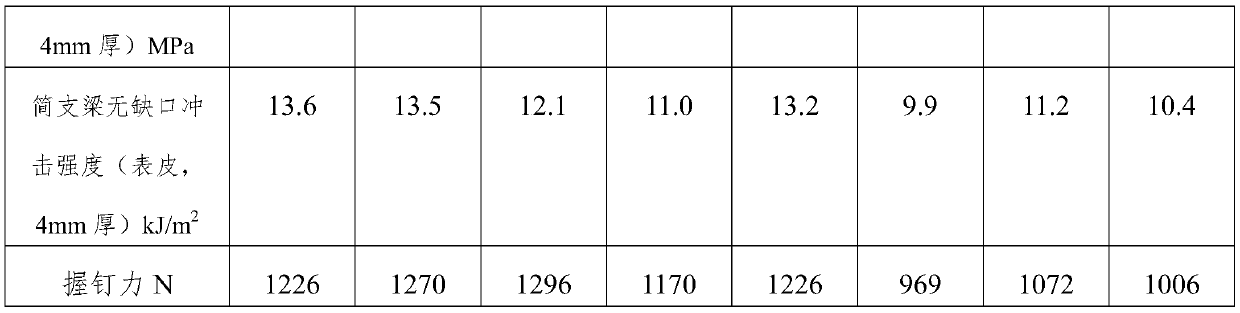

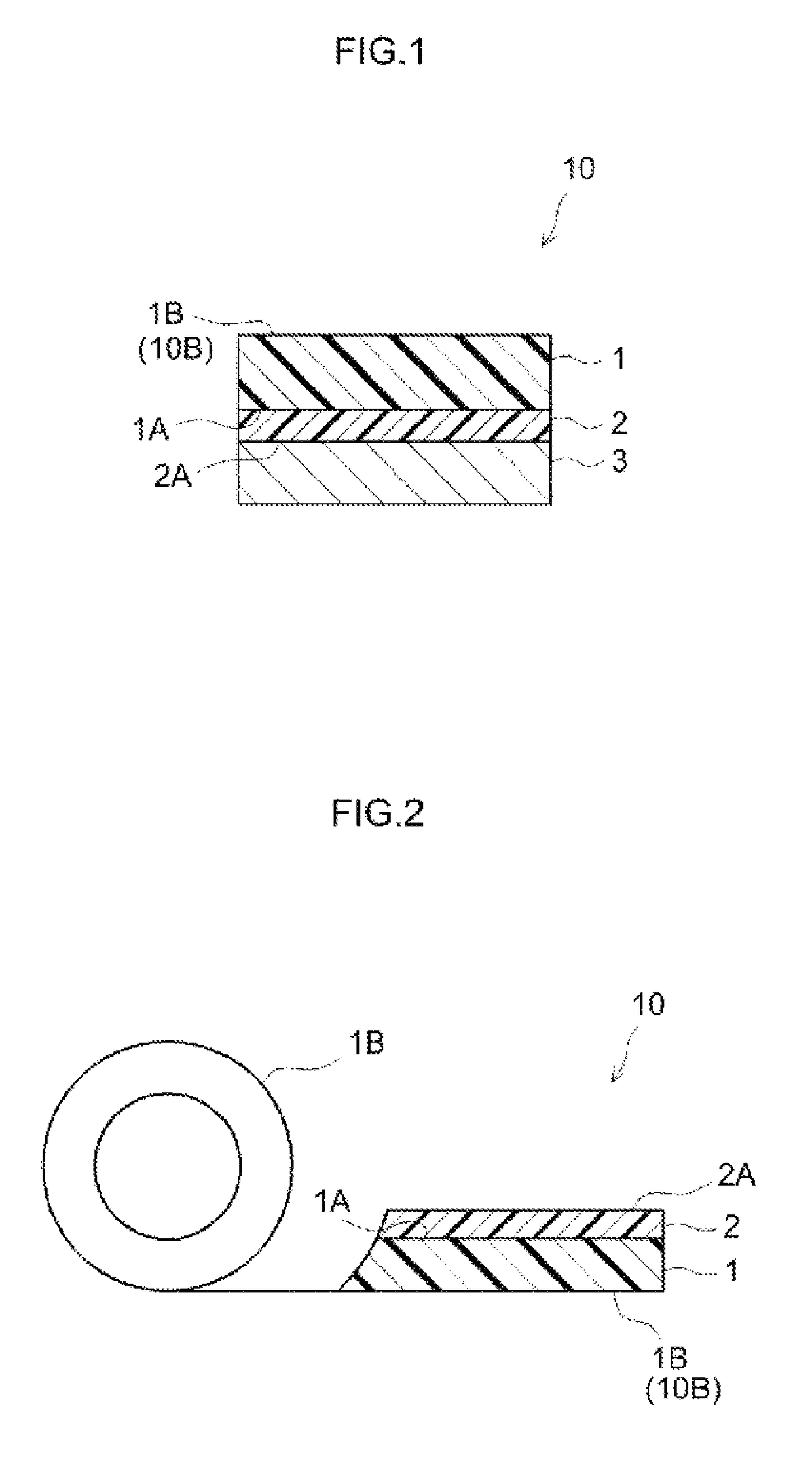

PVC (Polyvinyl Chloride) co-extruded sheet and production method thereof

ActiveCN109910413AHigh strengthGood weather resistanceSynthetic resin layered productsFiberAntioxidant

The invention embodiment discloses a PVC (Polyvinyl Chloride) co-extruded sheet and a production method thereof, and belongs to the technical field of composite materials. The PVC co-extruded sheet comprises a PVC surface layer and a PVC foamed filling layer, wherein the PVC surface layer is prepared from PVC resin, CPVC powder, PBO fibers, a stabilizer, a fire retardant and ground calcium carbonate powder; the PVC foamed filling layer is prepared from the PVC resin, the CPVC powder, the PBO fibers, the stabilizer, the fire retardant, the ground calcium carbonate powder, an impact modifier, talcum powder, an internal lubricant, oxidized polyethlene wax, magnesium oxide, a silane coupling agent, a foam regulator, an ultraviolet light absorber, an antioxidant and an antistatic agent. The PVCco-extruded sheet in the embodiment of the invention has good mechanical property, weather resistance and good promotion value, so that the limitations of an existing PVC foaming material used outdoors are overcome, the cost of outdoor landscape engineering is greatly reduced and further the use field of products is widened.

Owner:北京百草居生物科技集团有限公司

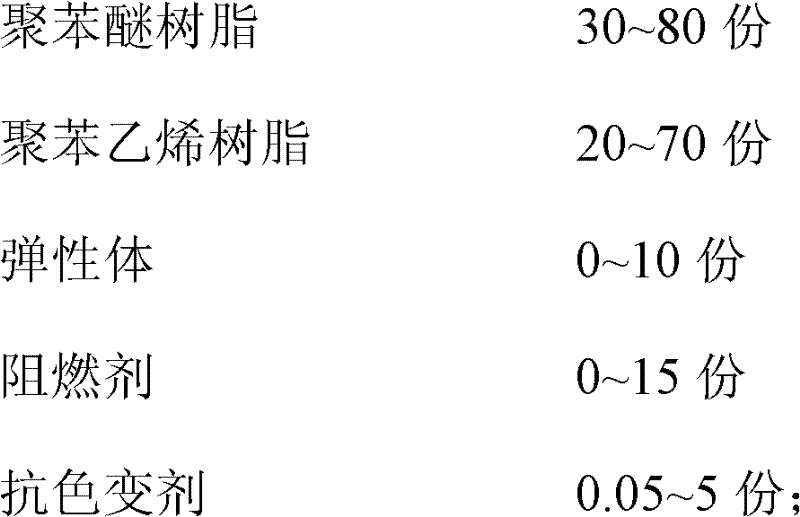

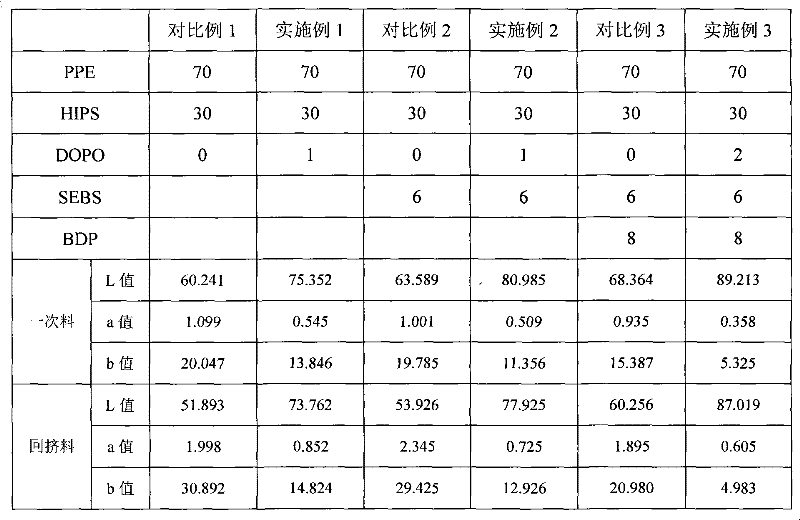

Polyphenylene ether resin composition and production method thereof

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL +1

Spectacle lens

ActiveUS7863354B2High light transmittanceImprove heat resistancePlastic/resin/waxes insulatorsOptical elementsHeat resistanceEyewear

A resin composition which contains polycarbonate resin, does not transmit a wavelength of 385 nm substantially and has a high total light transmittance and excellent heat resistance.The resin composition comprises (1) polycarbonate resin, (2) an ultraviolet absorber (A) such as 2-(2H-benzotriazol-2-yl)-p-cresol, (3) an ultraviolet absorber (B) such as 2,2′-methylenebis[4-(1,1,3,3-tetramethylbutyl)-6-(2H-benzotriazol-2-yl)phenol] and (4) at least one compound (C) represented by the following formula (I) or (II) and is used for spectacle lenses.(R1—S—CH2—CH2—C(O)O—CH2—)4C (I)(R2—O—C(O)—CH2—CH2—)2S (II)(wherein R1 is an alkyl group having 4 to 20 carbon atoms, and R2 is an alkyl group having 6 to 22 carbon atoms.)

Owner:TEIJIN KASEK KK

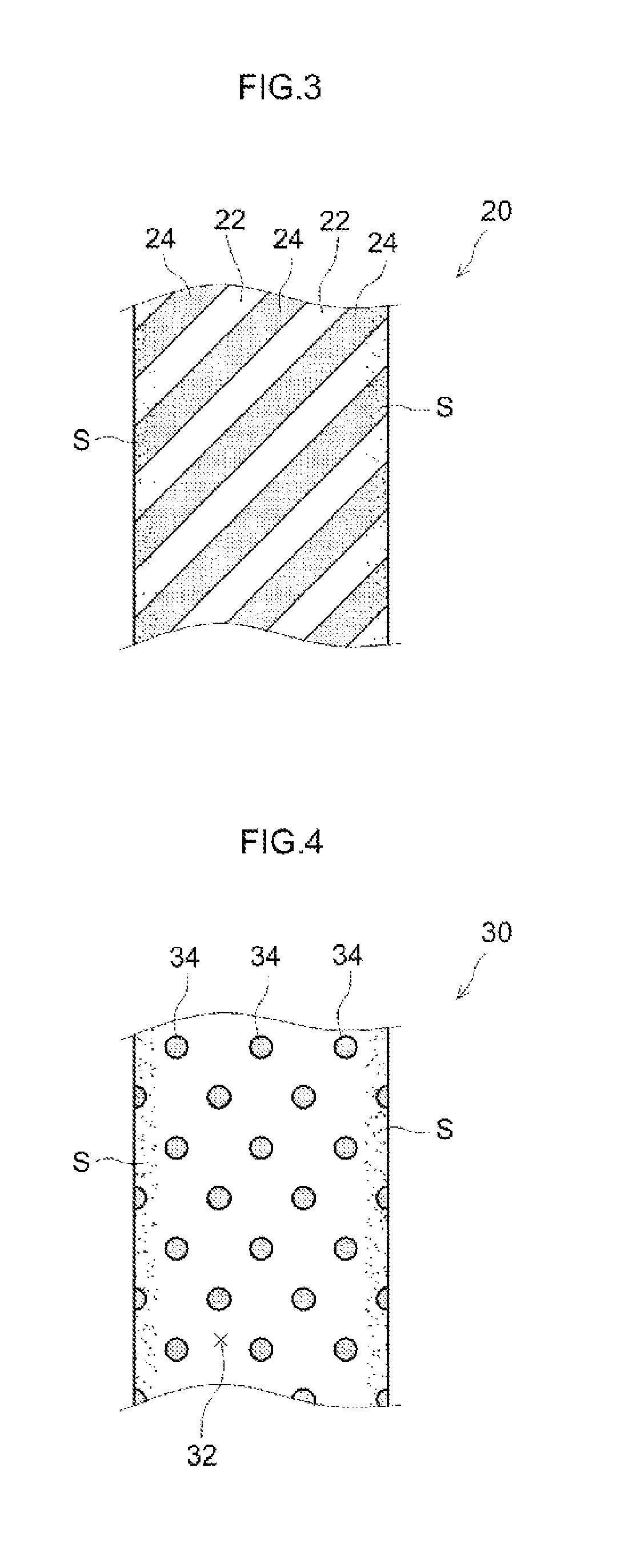

Masking sheet for chemical solution treatment

InactiveUS20170292042A1Improve removabilityGood flexibilityAnodisationNatural rubber adhesivesChemical treatmentChemical solution

Provided is a masking sheet for chemical solution treatment, the masking sheet comprising a substrate having first and second faces, and a PSA layer placed on the first face side of the substrate. The masking sheet is constituted so that penetration of a chemical solution is visually detectable when inspected from the outer face of the masking sheet.

Owner:NITTO DENKO CORP

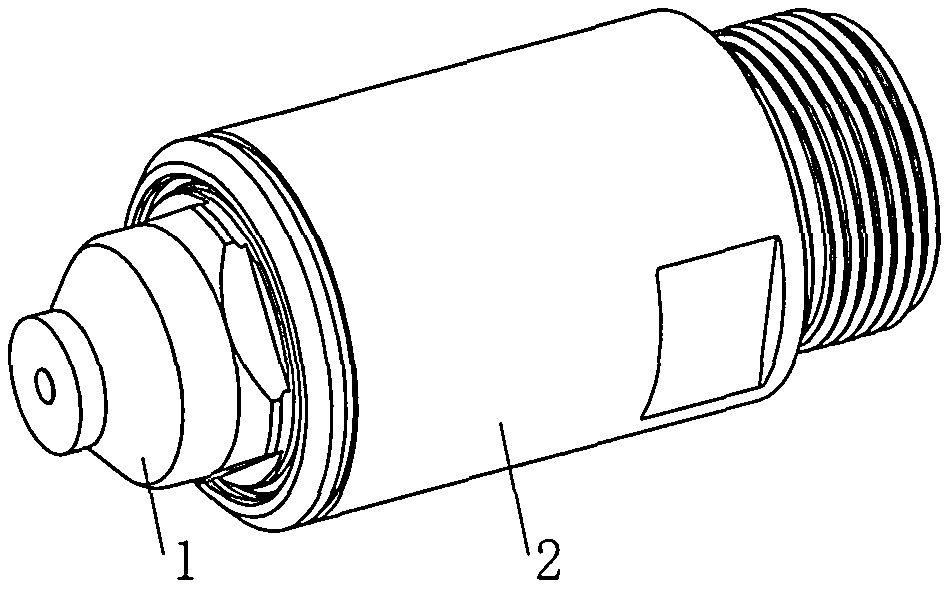

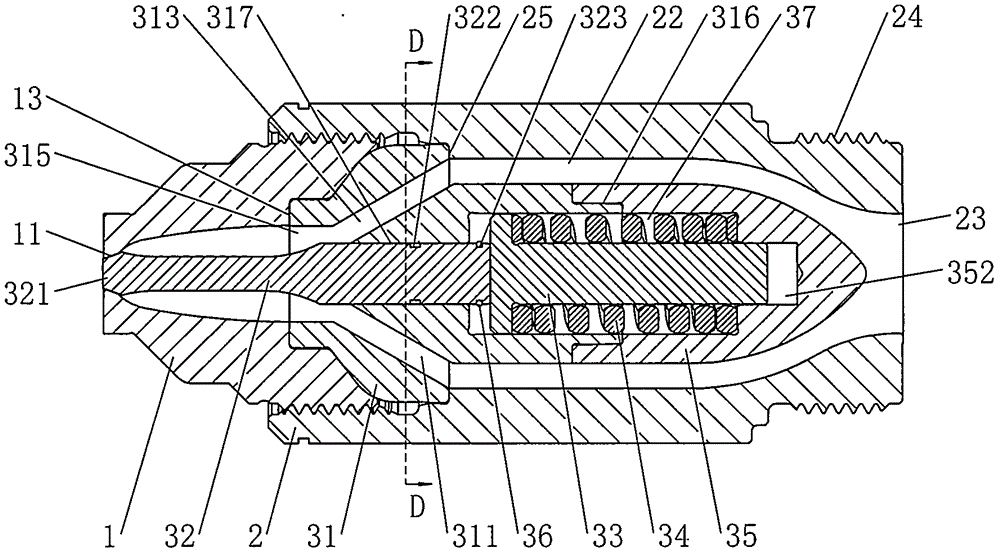

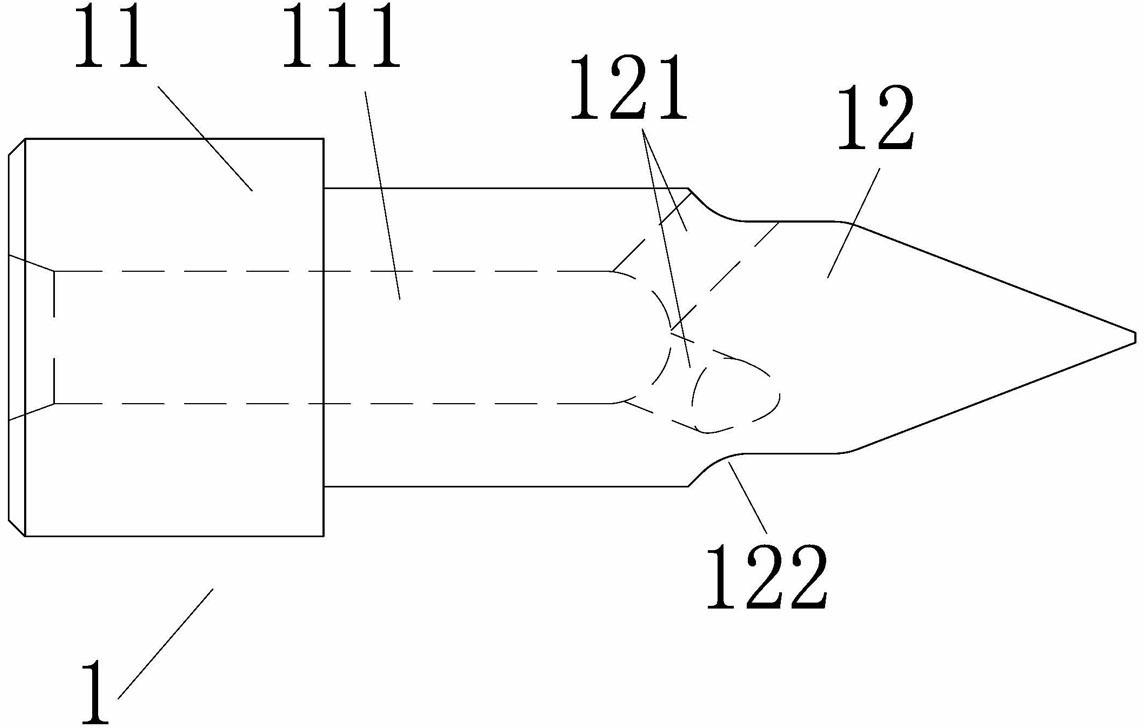

Direct-injection sprue type passive needle valve

InactiveCN105937631AImprove color changeReduce stitching gapLift valveValve housingsColor changesBiomedical engineering

A direct-injection sprue type passive needle valve comprises a valve mouth, a valve body and a valve core. The valve core is majorly composed of a valve core body, a valve needle, a push rod, a spring and a valve core lid. At least two sub-runners are evenly distributed on the valve core in the circumferential direction. A stepped through hole is formed in the center of the valve core body. A stepped hole is formed in the center of the valve core lid. The stepped hole of the valve core lid and the stepped through hole of the valve core body are jointed in a butt joint mode to form a cavity. The push rod and the spring are arranged inside the cavity. The valve needle is arranged in the stepped through hole of the valve core body. The valve mouth is arranged at one end, close to the valve needle, of the valve core in a sleeving mode. The other end of the valve core is sleeved with the valve body. A passageway is formed from a small hole end of the valve body to a center ejection opening of the valve mouth. According to the direct-ejection sprue type passive needle valve, the flow resistance inside the sub-runners in the needle valve is reduced, the color changing property of the passive needle valve is improved, the difficulty of assembling and maintenance is reduced, the maintenance time period is shortened, and the cost of after-sales service is reduced.

Owner:高建鸣

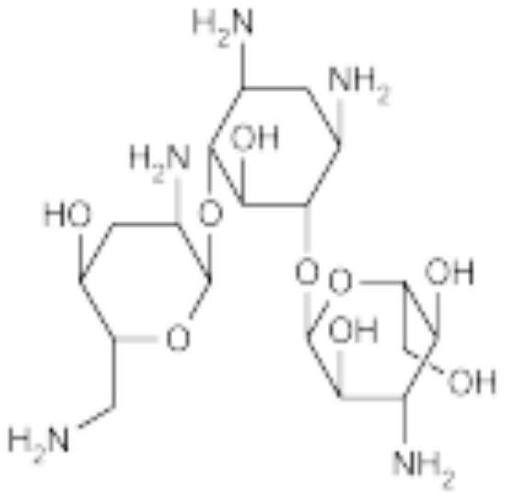

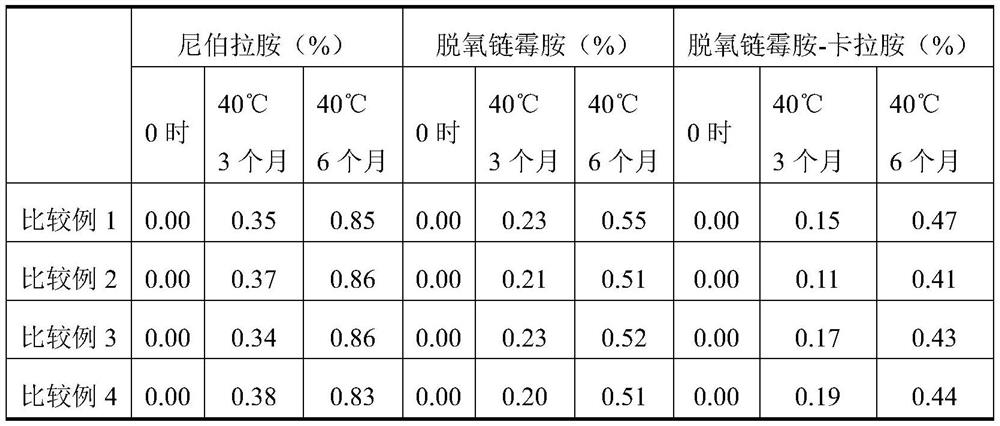

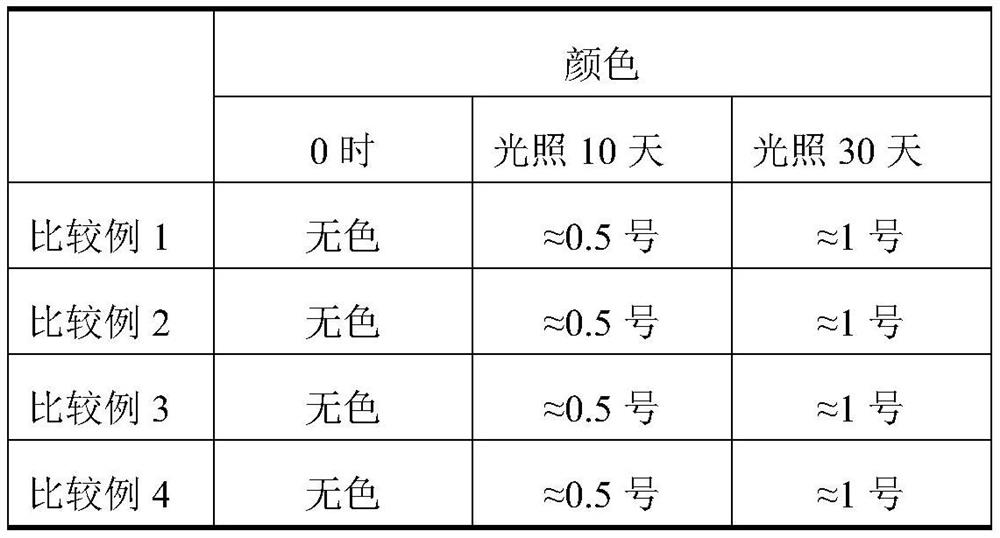

Packaging container for inhibiting color change of tobramycin eye drops and preparation method thereof

The invention relates to a packaging container for inhibiting color change of tobramycin eye drops and a preparation method of the packaging container. The existing tobramycin eye drops have the defect of unstable quality caused by color change during the stability inspection period, so that the invention provides a novel method for stabilizing the tobramycin eye drops, namely, a color master batch containing specific titanium dioxide is added into a container material of a tobramycin eye drop packaging container; the color of the tobramycin eye drops is kept unchanged during the stability inspection period, and the product quality is improved, so that the clinical curative effect of the tobramycin eye drops is ensured.

Owner:SHENYANG XINGQI PHARM CO LTD

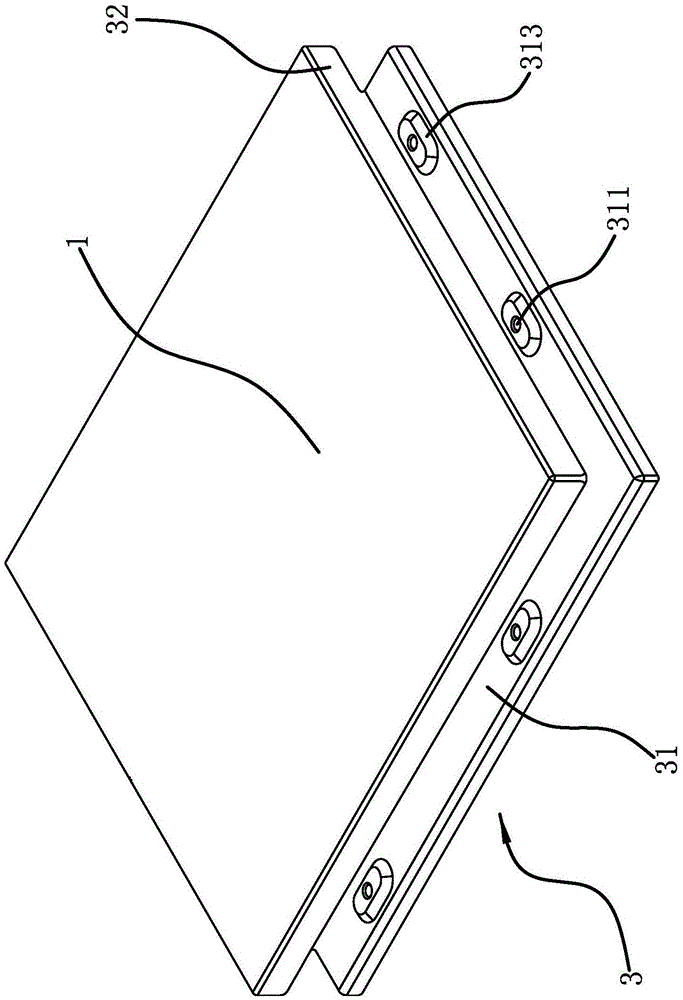

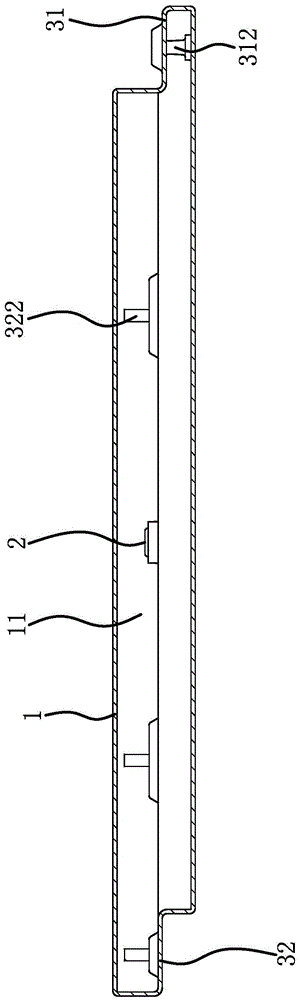

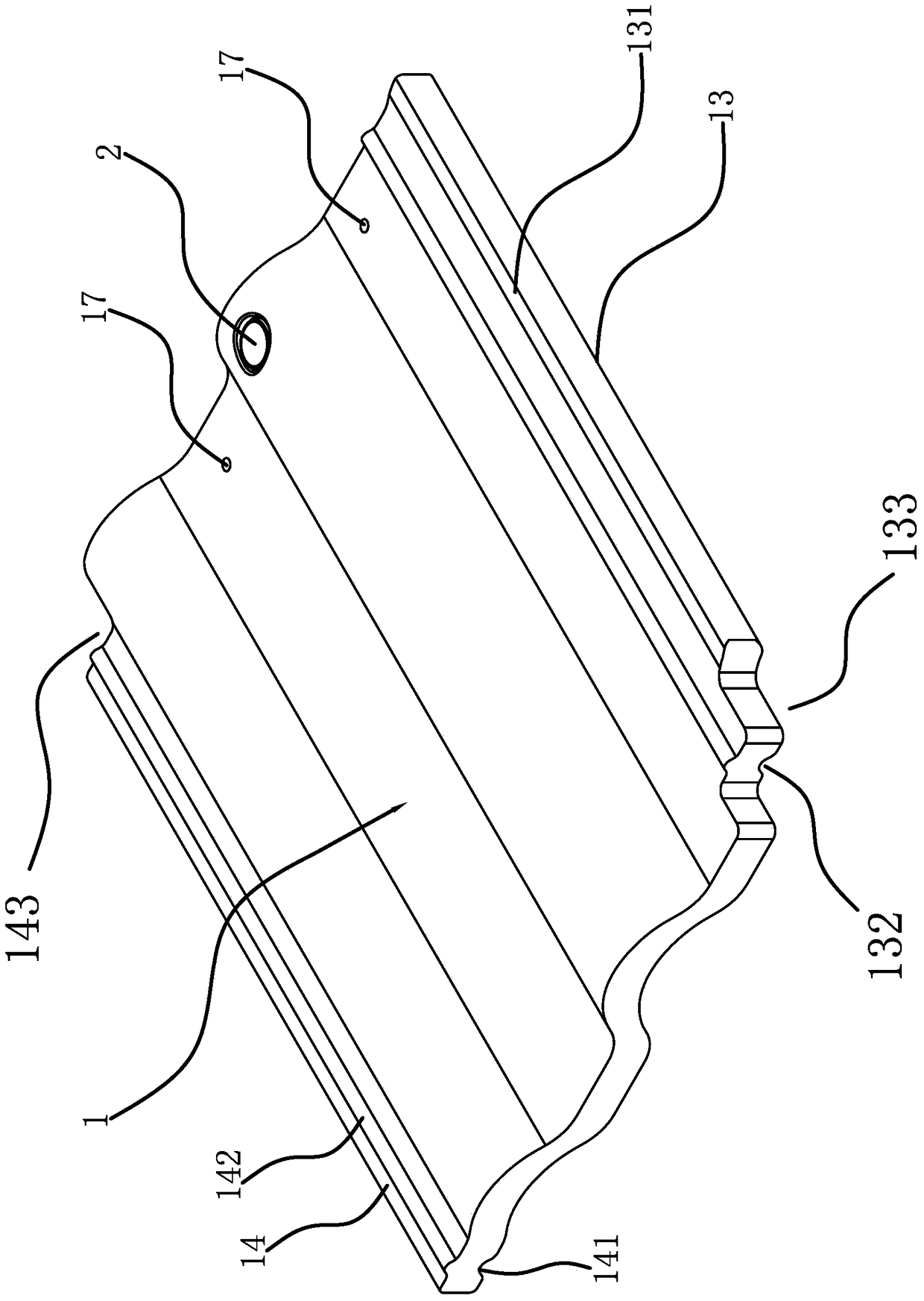

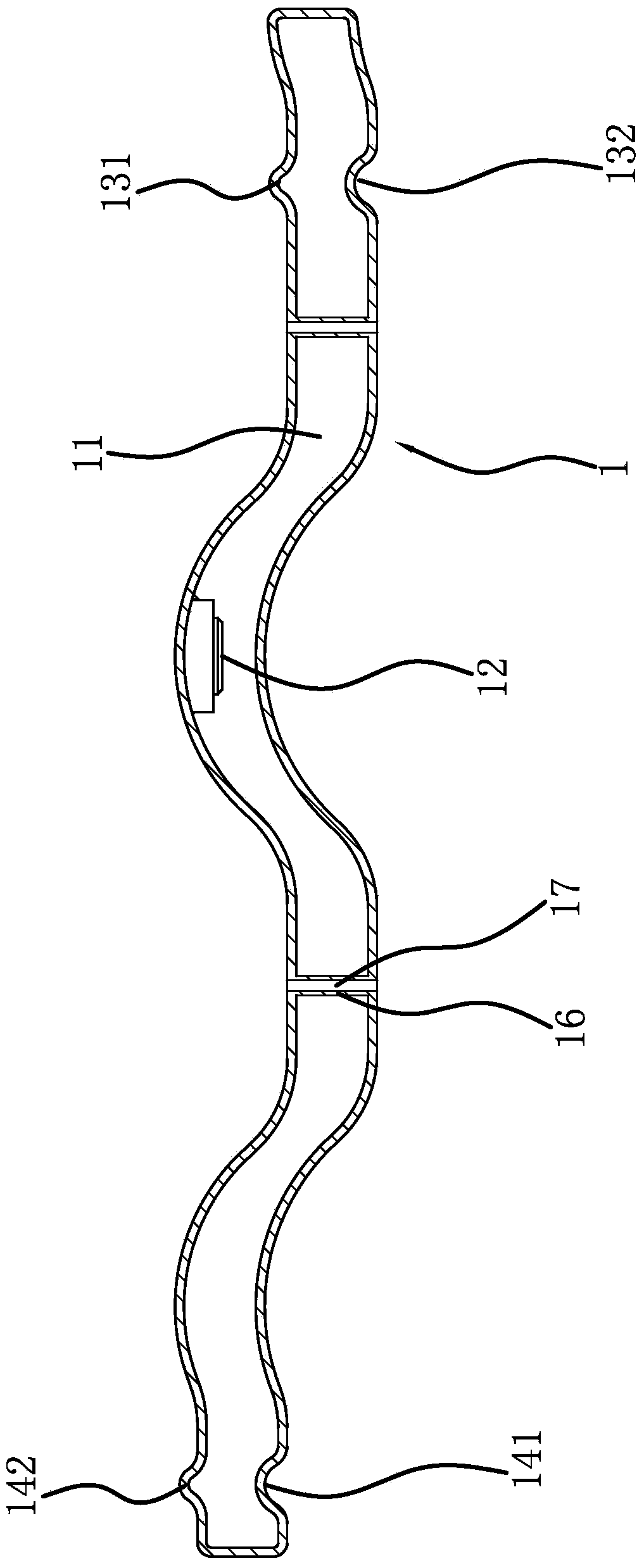

Plastic wall plate

InactiveCN105544847AWith structural strengthResistant to stressConstruction materialWallsBlow moldingEngineering

The invention provides a plastic wall plate which is formed by using a hollowing blow molding and rotational molding process at one time and can be used in the technical field of building materials, and aims to solve the problems that building materials of a conventional building, particularly a temporary house, are relatively troublesome to transport and mount and relatively poor in strength, heat preservation and sound insulation effect. The plastic wall plate comprises a rectangular main body, wherein the main body is of a hollow structure which is manufactured by using a hollow plastic process; a sealed storage cavity is formed in the main body; the shape of the storage cavity adapts to that of the main body; the storage cavity can be filled with a material which can improve the functional properties of the wall plate; a feeding hole is formed in the main body; the feeding hole is communicated with the storage cavity; a plug which can be mounted, dismounted and used for sealing the feeding hole is arranged inside the feeding hole; the main body is made of plastic; the main body is further provided with a connecting structure for fixedly connecting two adjacent main bodies together. The plastic wall plate is simple to transport and mount, has the advantages of fire resistance, cold prevention, heat preservation, pressure resistance, sound insulation, durability and the like, and is green, energy-saving and environment-friendly as the material can be recycled and reused.

Owner:林红建

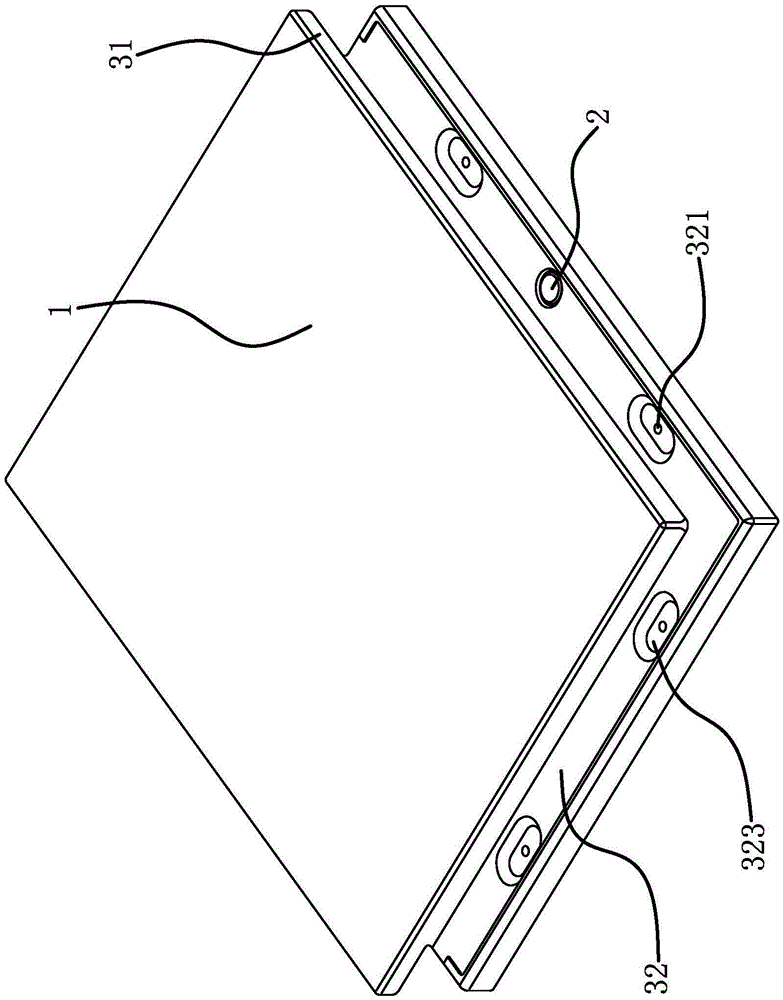

Plastic tile

InactiveCN105484432AWith structural strengthResistant to stressRoof covering using tiles/slatesBlow moldingThermal insulation

The invention provides a plastic tile. The plastic tile is formed in one step according to a hollow blow molding and rotomolding process, is applied to the technical field of building materials and solves the problems that the conventional tile is heavy and frangible in transportation, undesirable in shock, pressure and cold resistance and thermal insulation and the like. The plastic tile comprises a platy body which is manufactured according to the hollow plastic technology, a sealed material storage cavity which is matched with the body in shape is formed in the body and can be filled with a material capable of enhancing the functional attributes of the tile, a feed opening is formed in the upper side surface of the body, communicated with the material storage cavity, and located on the edge of the body, and a detachable plug which can seal the feed opening is arranged in the feed opening. The plastic tile is relatively light in transportation, has the fire, cold and pressure resisting and thermal insulating effects, and can be recovered, thereby being low in energy consumption and environmentally friendly.

Owner:林红建

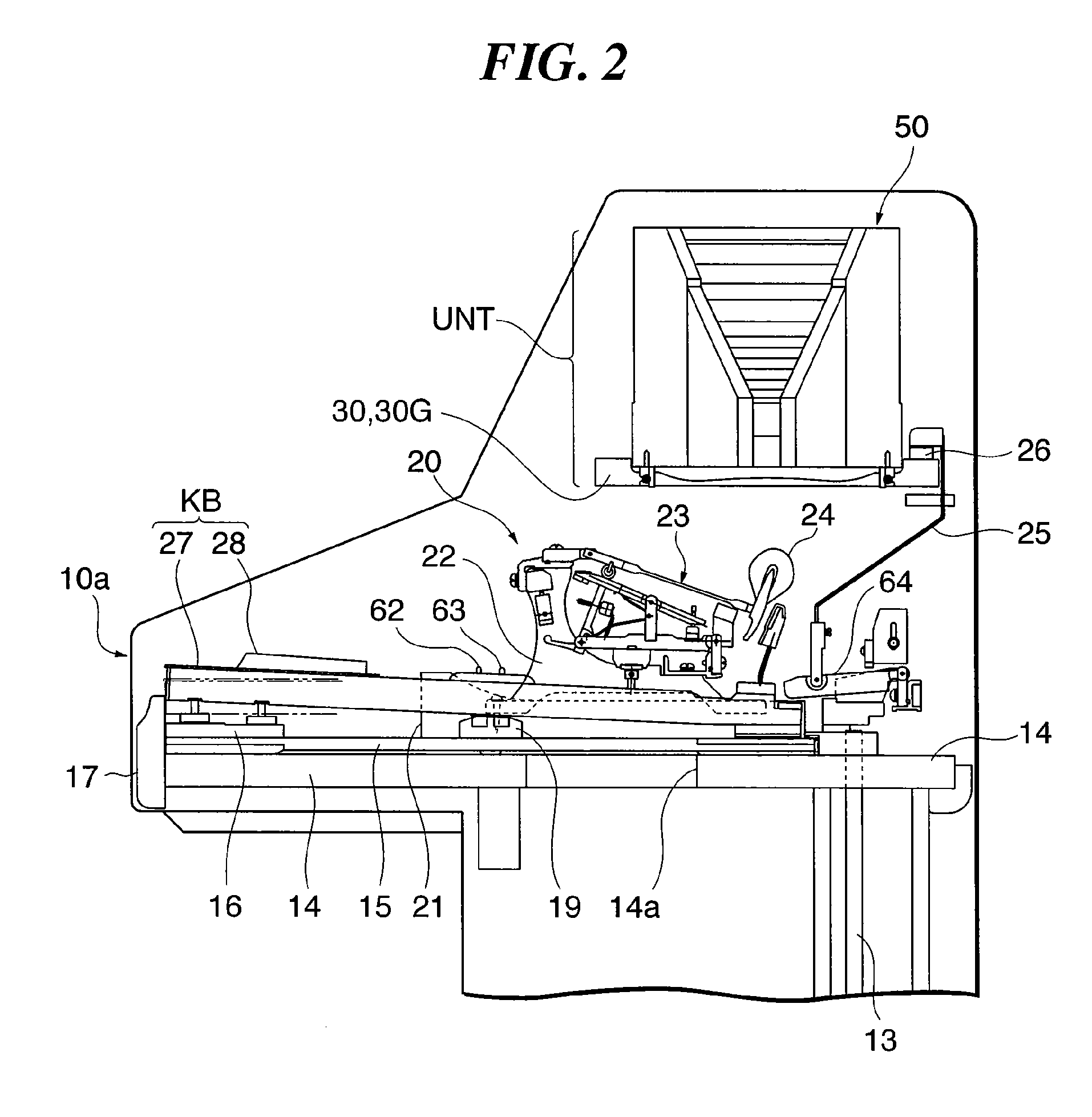

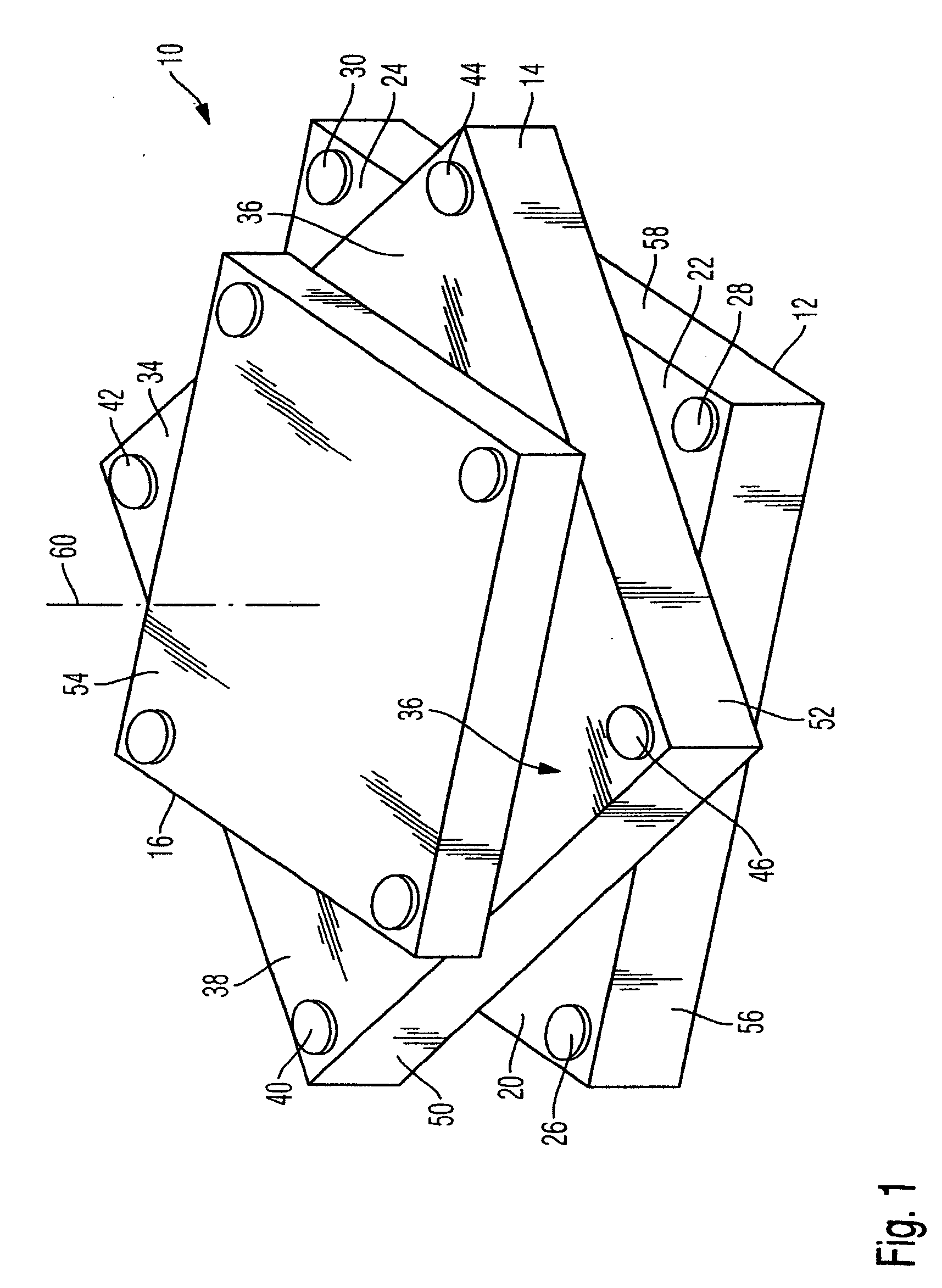

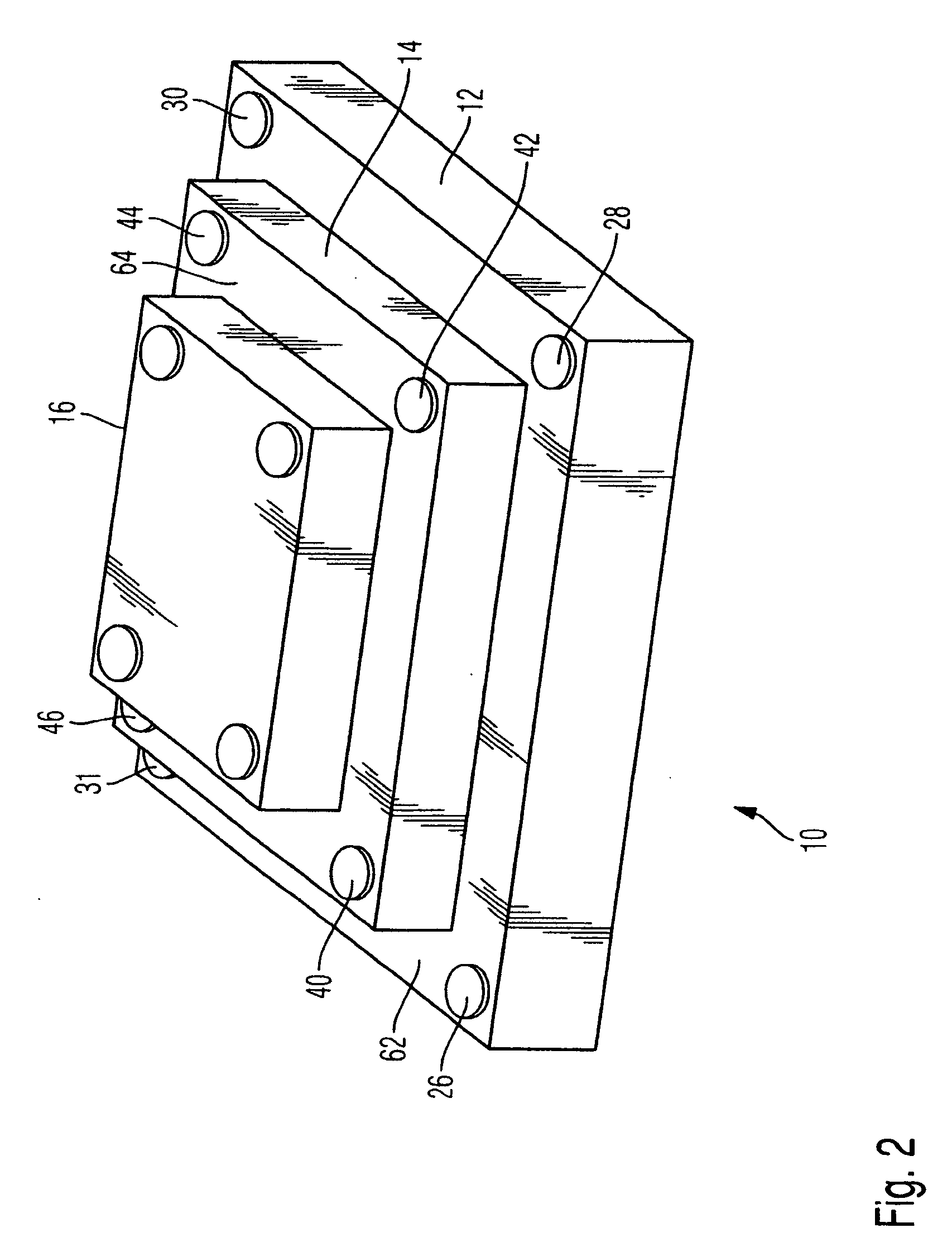

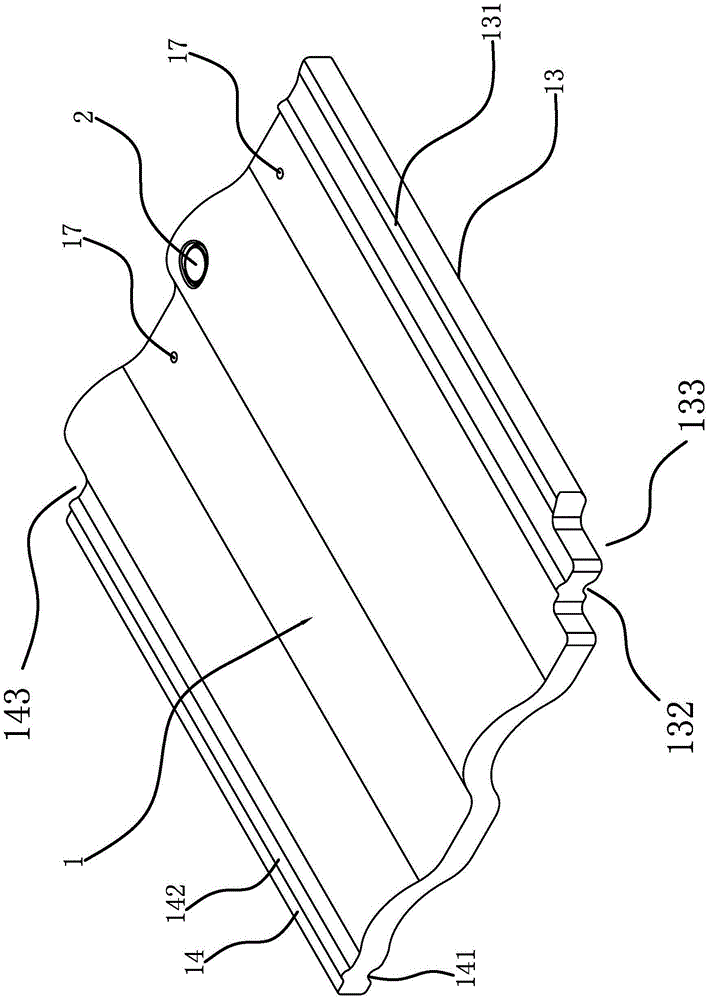

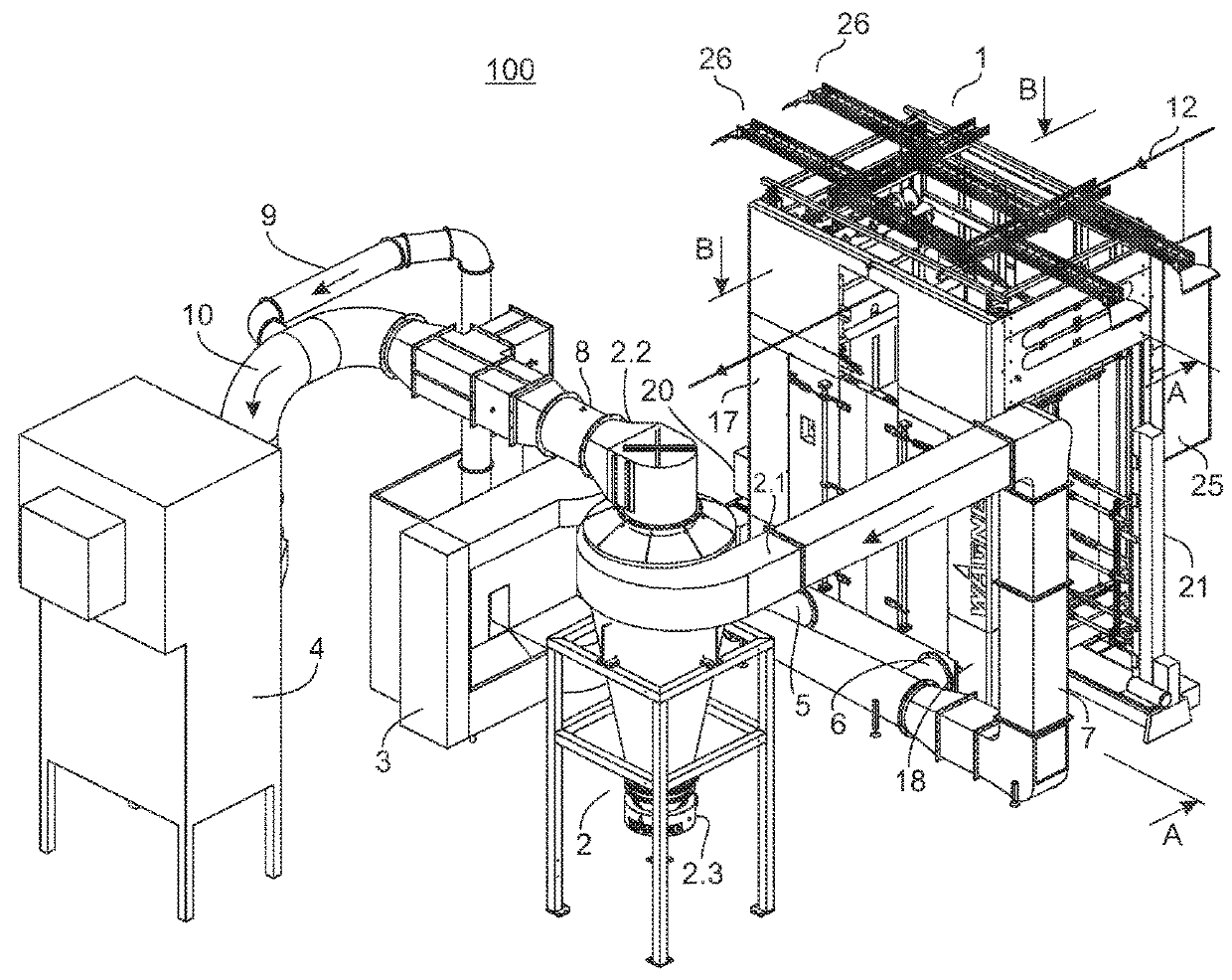

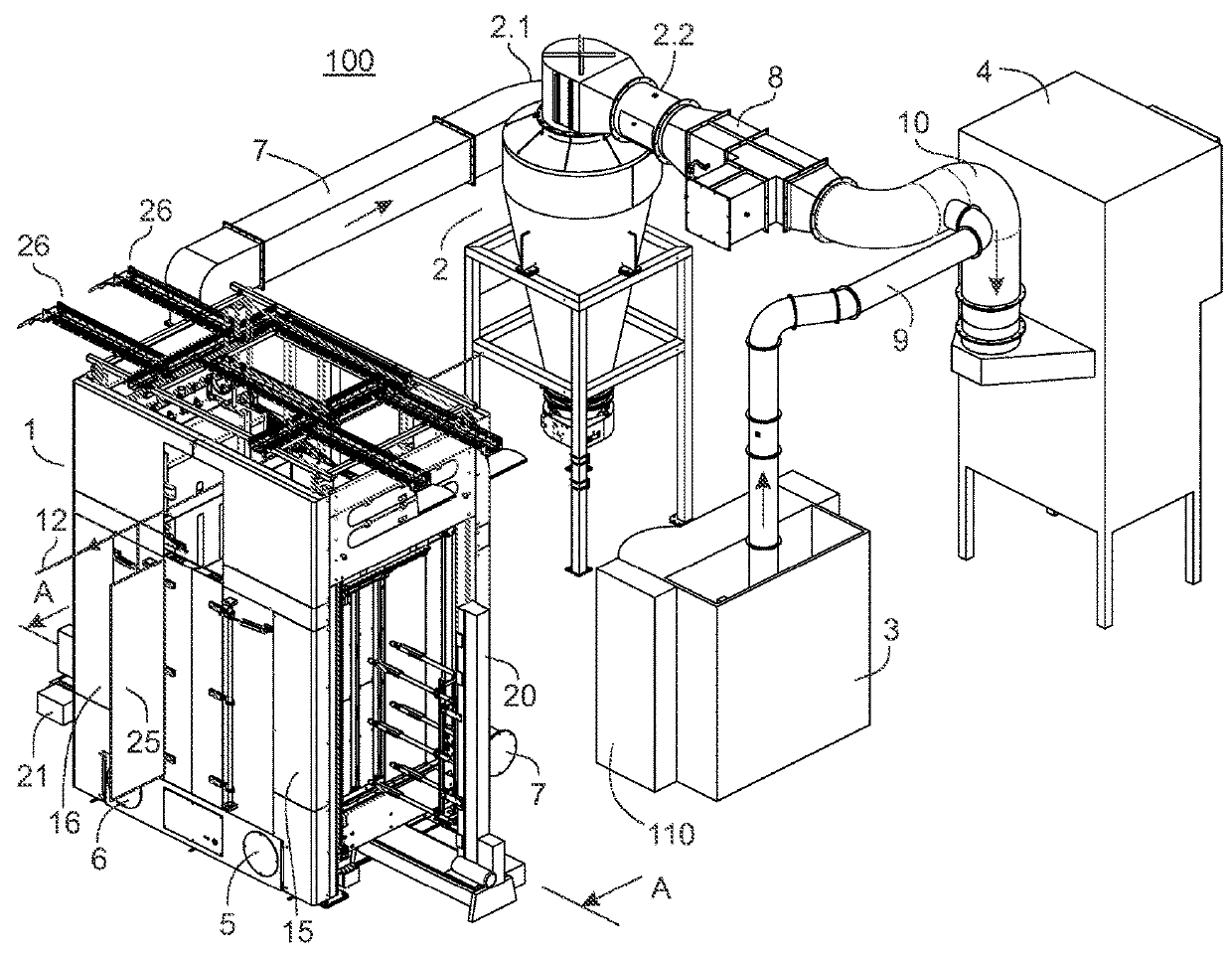

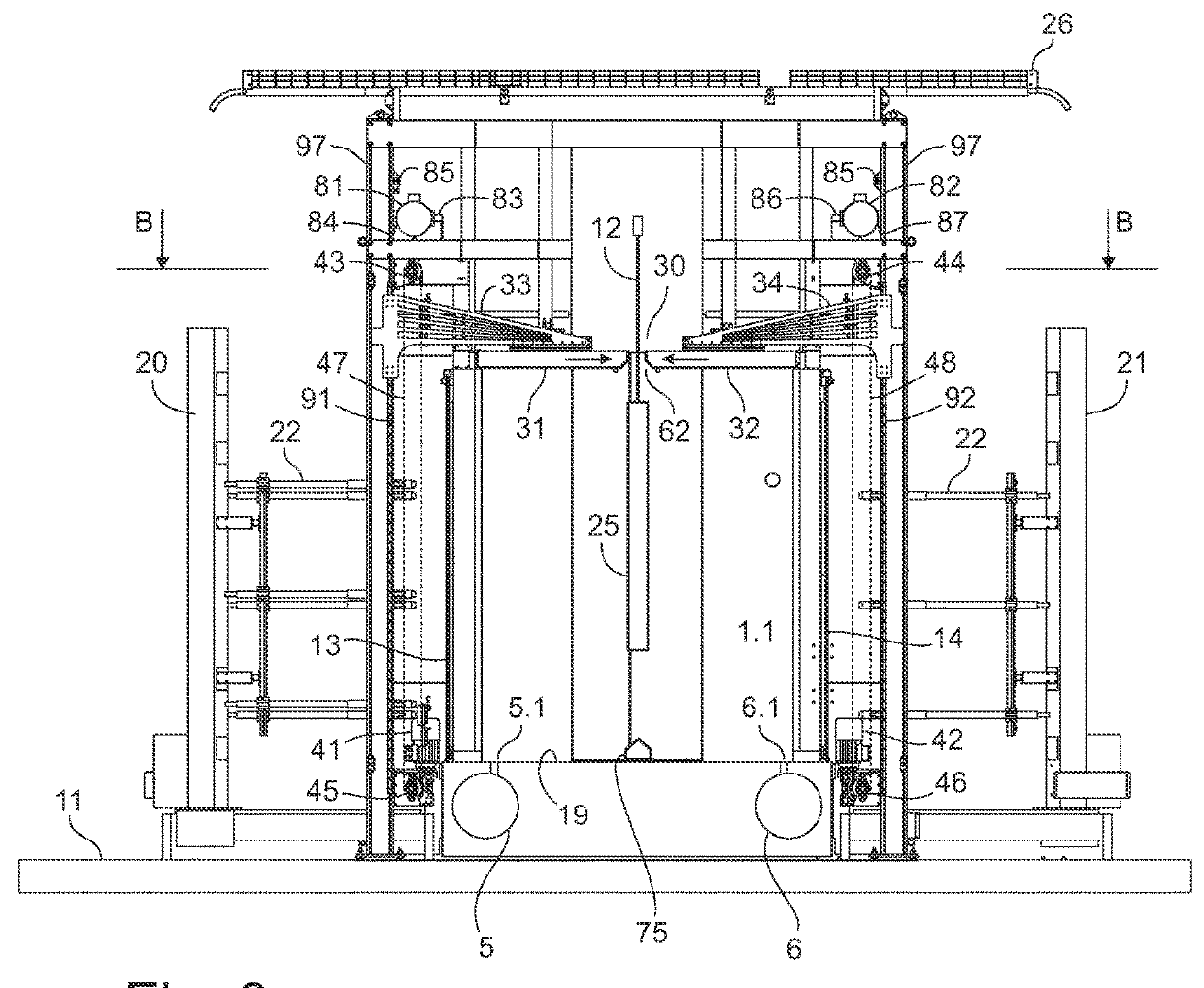

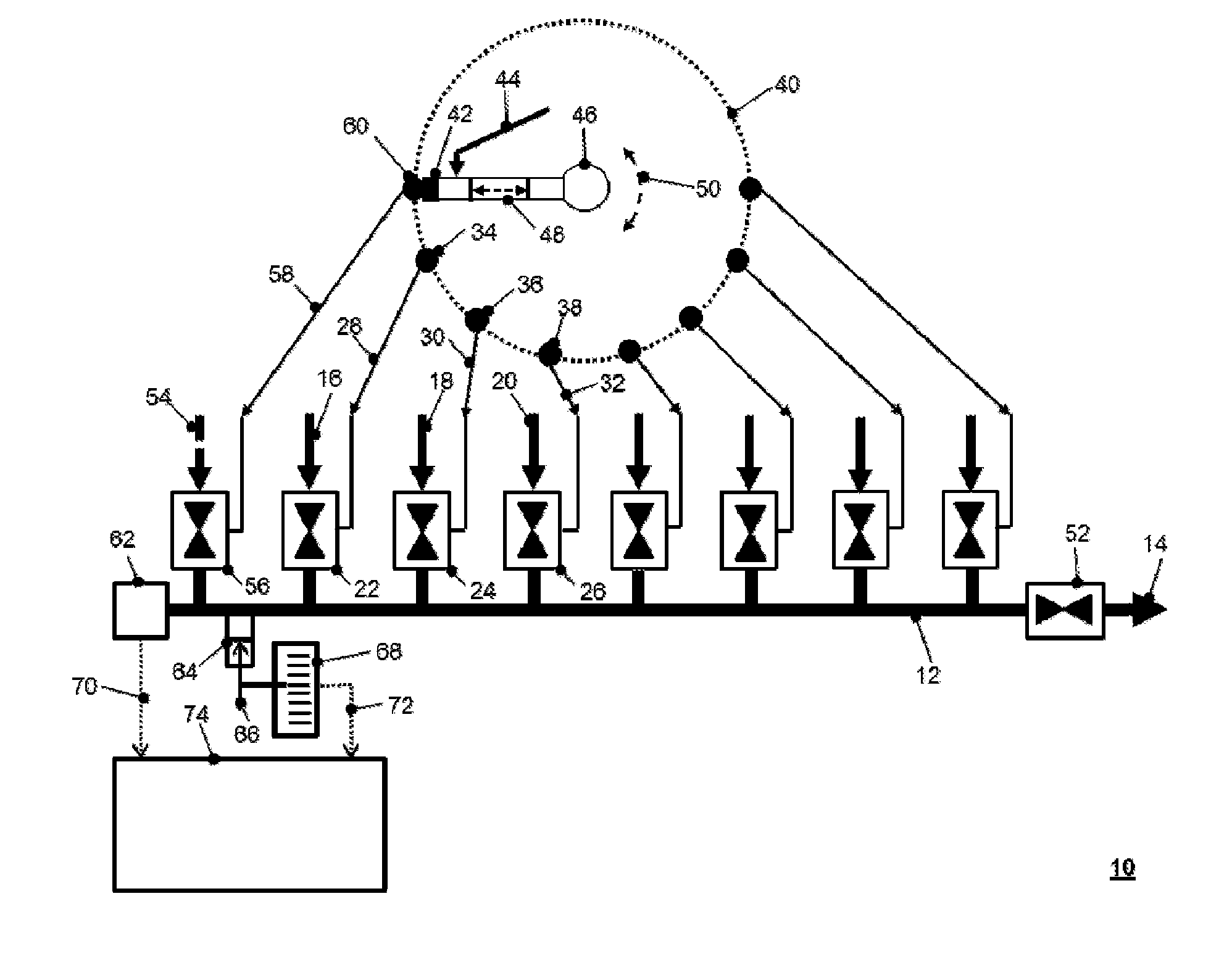

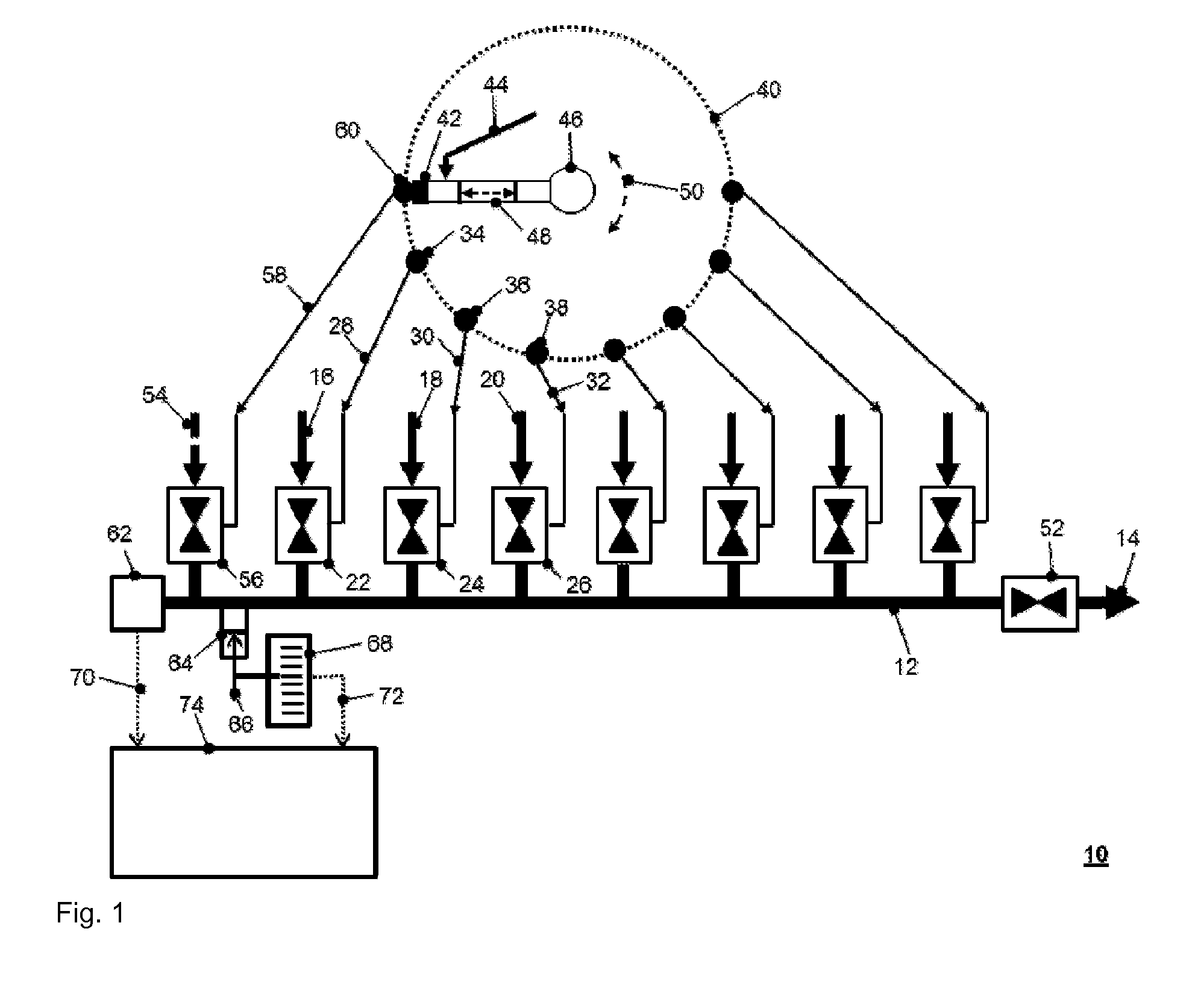

Powder coating booth, powder coating installation and method for operating the powder coating booth

The powder coating booth according to the invention comprises booth walls (13-18) and a roof (30) which can be lowered between the booth walls (13-18), wherein a gap (60) is provided between the roof (30) and the booth walls (13-18). The roof (30) has compressed air nozzles (70) for spraying the booth walls (13-18). In addition, a supporting device (33-36) is provided, which supports the roof (30). In at least one of the booth walls (13 18) a vertical slot (61) is provided through which the supporting device (33-36) protrudes into the booth (1) and in which the supporting device (33-36) is movable. In addition, the booth comprises a bottom (19) with a suction (5, 6), which is connectable with the suction inlet (2.1) of a cyclone separator (2) via a suction pipe (7).

Owner:WAGNER INT

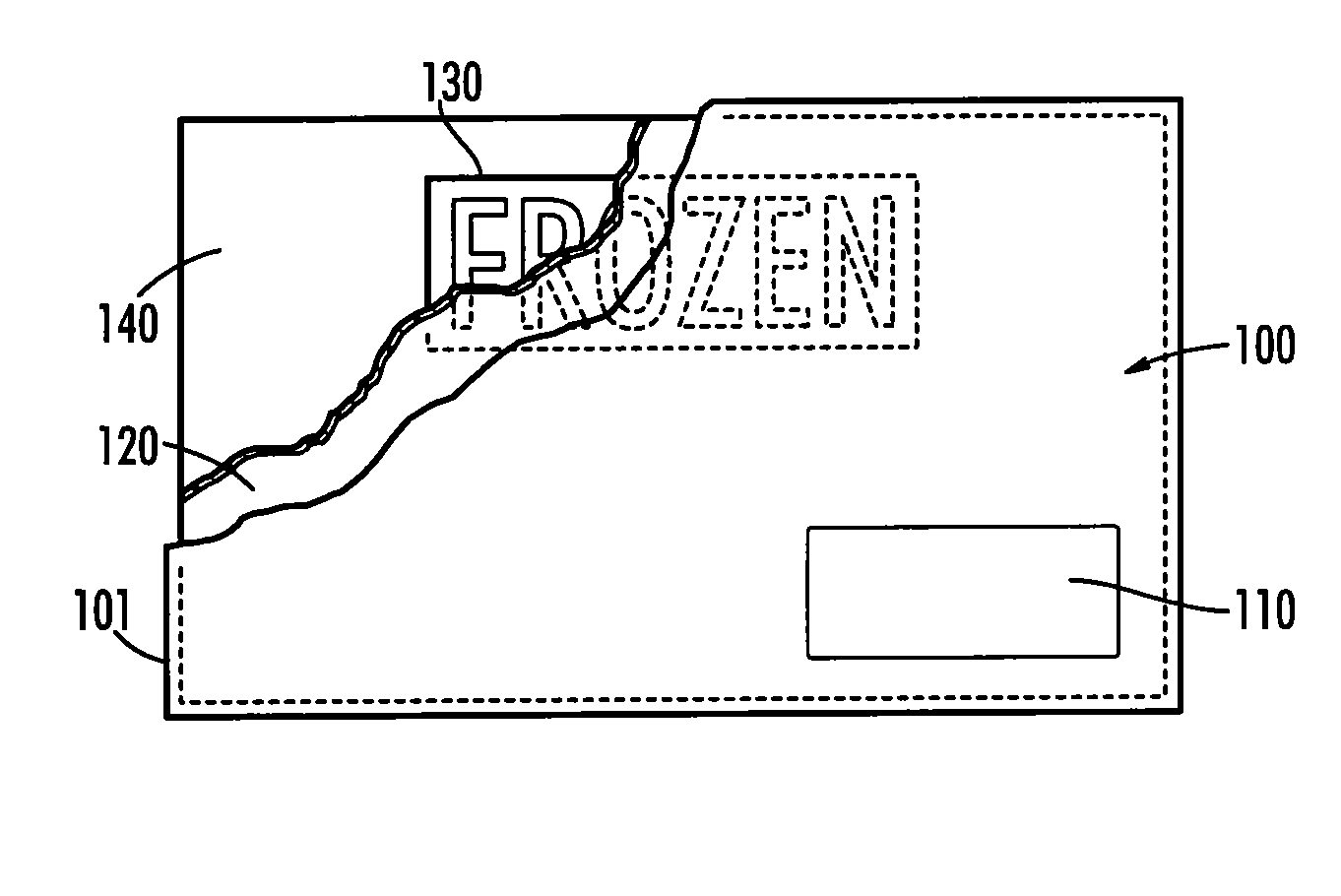

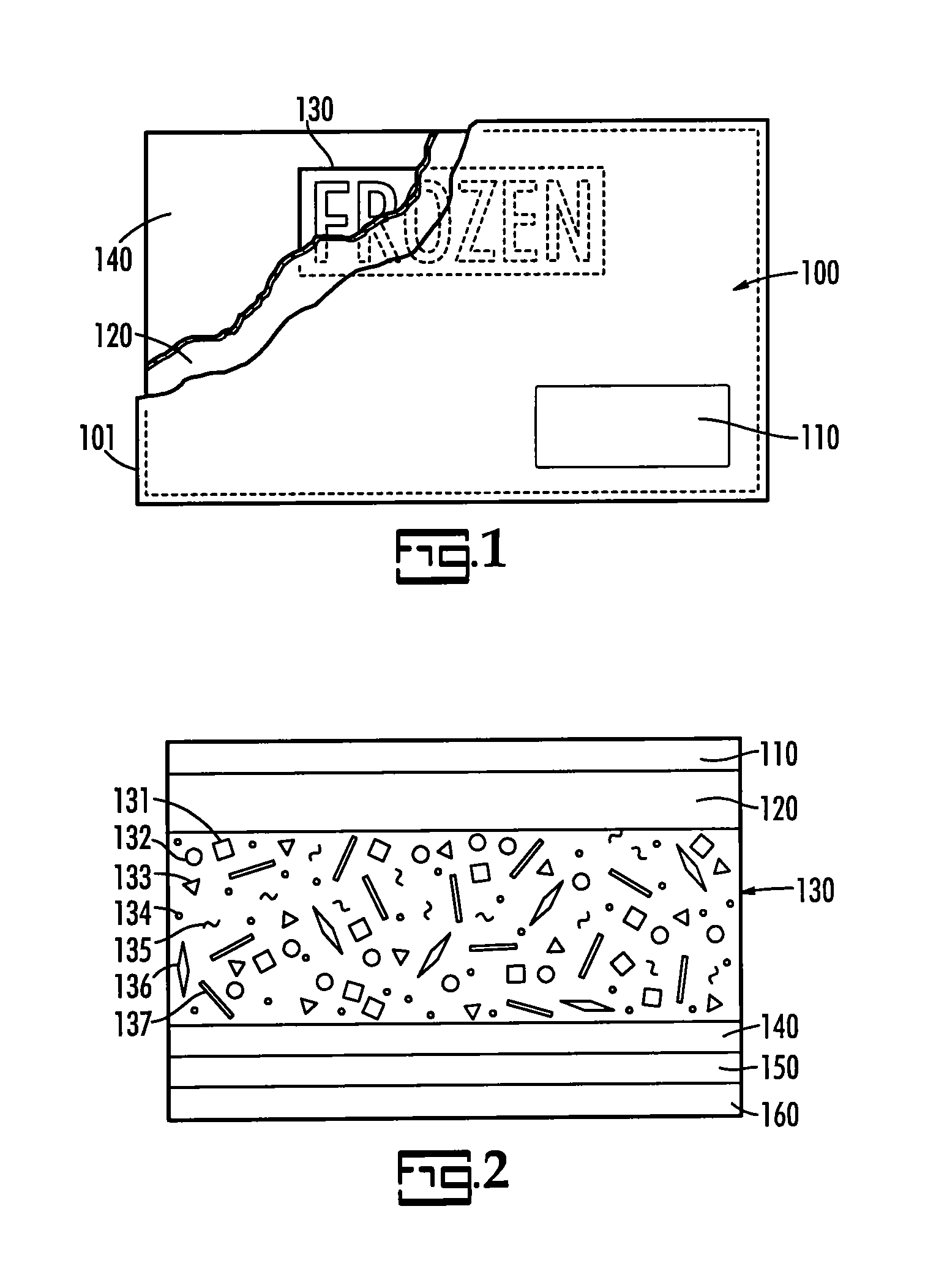

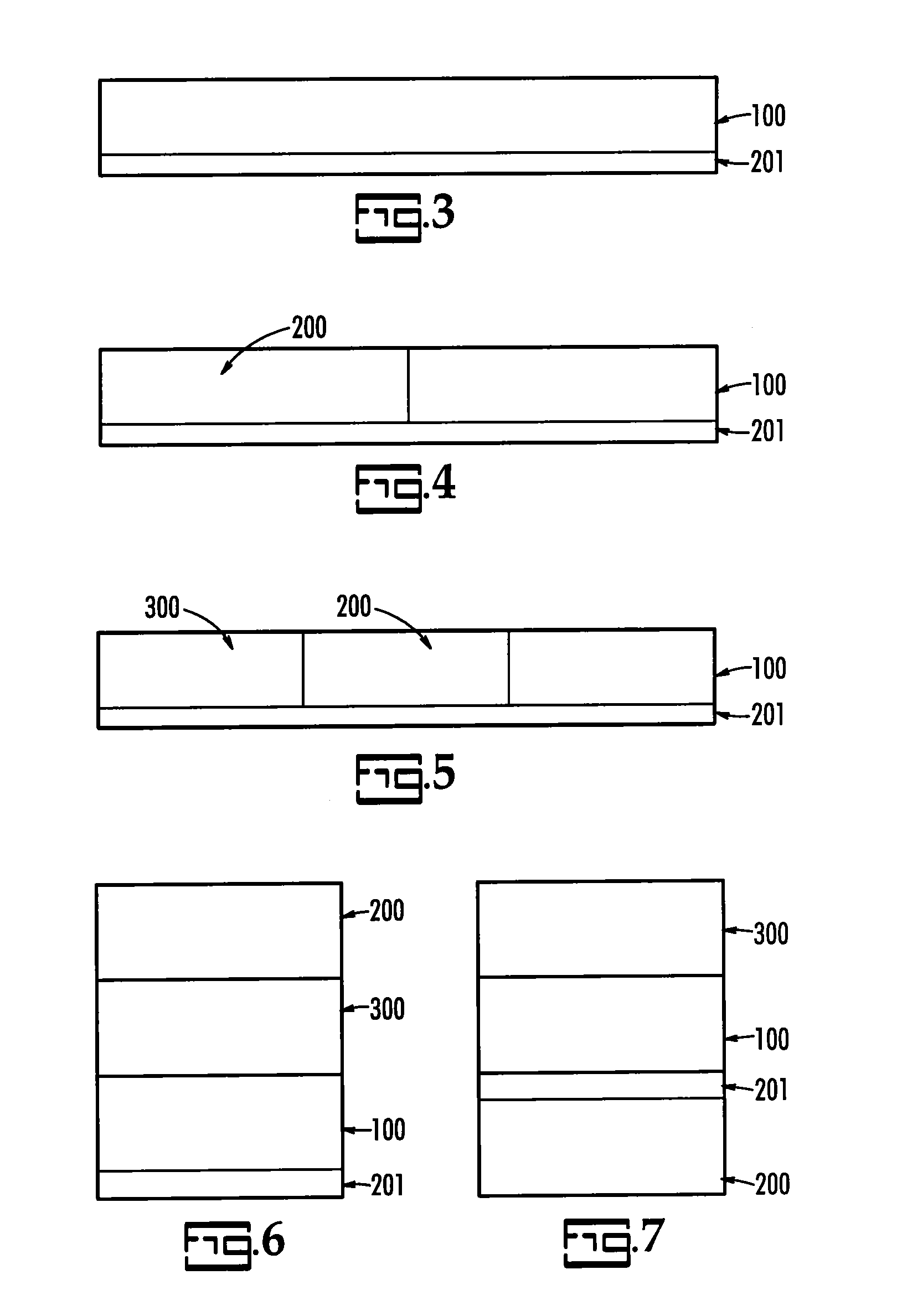

Freeze, thaw and refreeze indicators based on rapid reactions in the solid state

ActiveUS9581504B2Improve stateImprove color changeThermometer detailsThermometers using mean/integrated valuesDiacetyleneAnalytical chemistry

A freeze indicator, which is preferably a self-activating freeze indicator. The freeze indicator has a substrate with a freeze indicator composition coated thereon wherein the freeze indicator has a liquid diacetylene; and a catalyst or catalyst precursor and a protective cover.

Owner:JP LAB INC

Color-changer

InactiveUS20150217317A1Improve color changeMeasurement of fluid loss/gain rateSpraying apparatusEngineeringVALVE PORT

Owner:ABB (SCHWEIZ) AG

External medicine for removing nevus, warts and hidroma and preparation method of external medicine

PendingCN111265642AImprove permeabilityShort duration of actionPharmaceutical delivery mechanismPteridophyta/filicophyta medical ingredientsSmoked PlumTopical medication

The invention relates to an external medicine for removing nevus, wart and hidroma and a preparation method thereof. The external medicine for removing the nevus, the wart and the hidroma is mainly prepared from the following traditional Chinese medicines: curcuma aromatica, curcuma zedoary, brucea javanica powder, old salt, kalimeris indica, kalimeris indica, rhizoma cyperi, smoked plums and horsetail. The external medicine can be used for effectively removing nevus, wart and hidroma without leaving scars, and is simple to use.

Owner:山西女仁馨美容有限公司

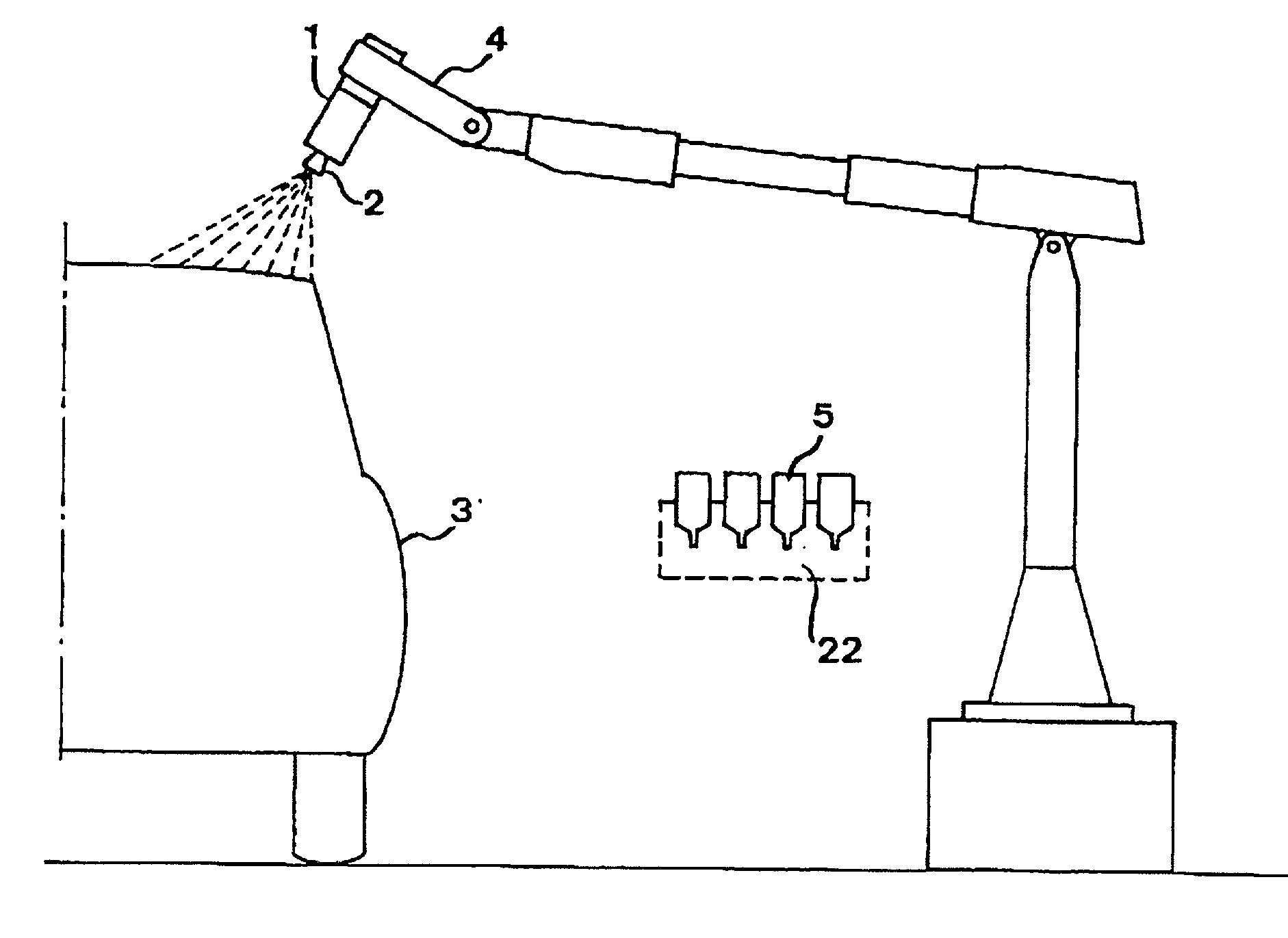

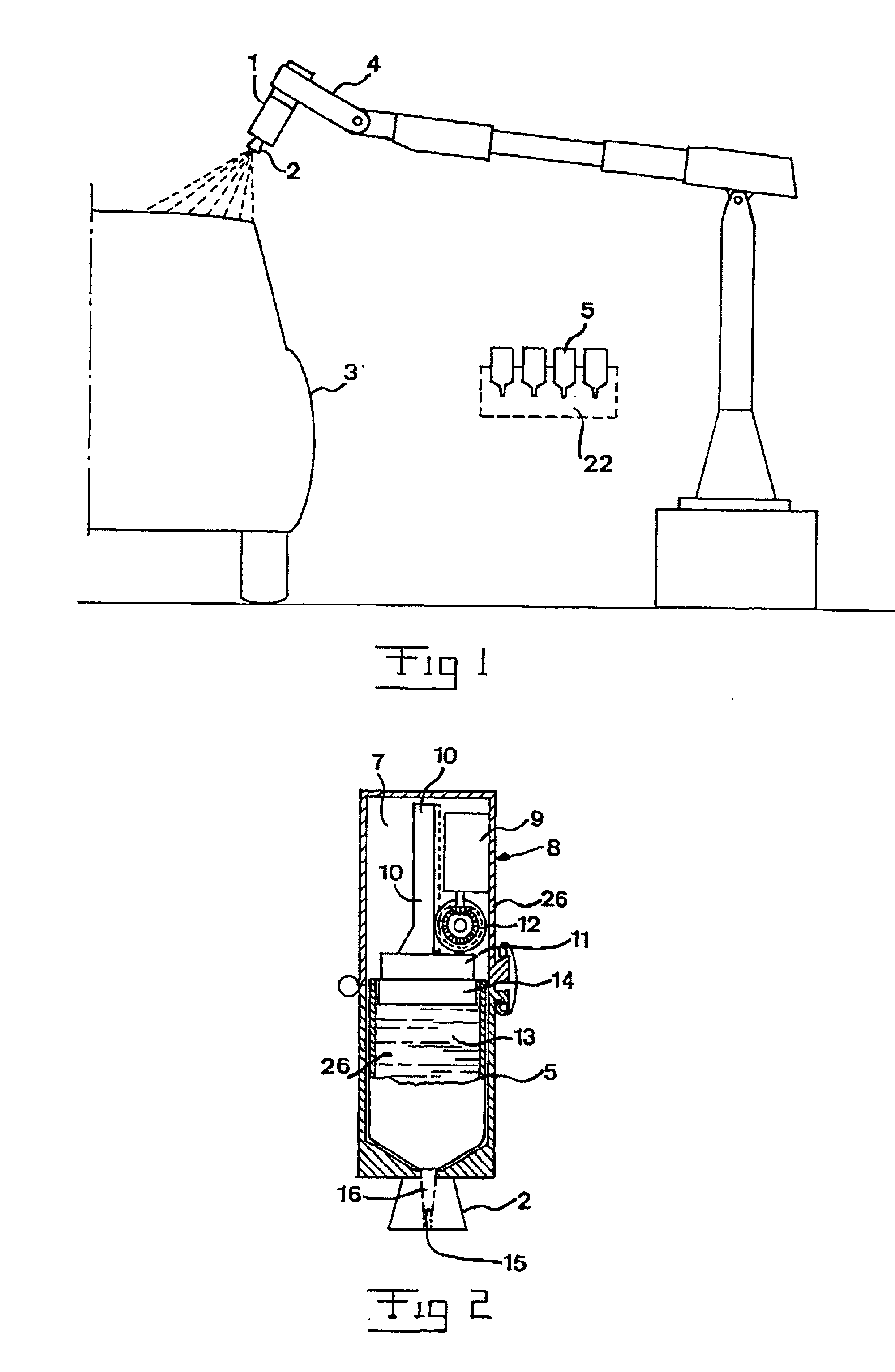

Device for automatic spray application of paint

InactiveUS20020056722A1Increase pump powerHigh viscosityLiquid supply arrangementsLarge containersSpray nozzleEngineering

In a device for automatic spray application of paint through a spray nozzle a unit providing paint is arranged to be connected to the nozzle (2) during the application for providing this with paint, and this unit is formed by a paint container (5) adapted to be arranged close to the spray nozzle. The device has members adapted to receive and hold the container close to the spray nozzle detachably and removably from the device for exchange thereof against such containers when there is a desire of more paint in the container and / or paint change.

Owner:ABB FLEXIBLE AUTOMATION AS

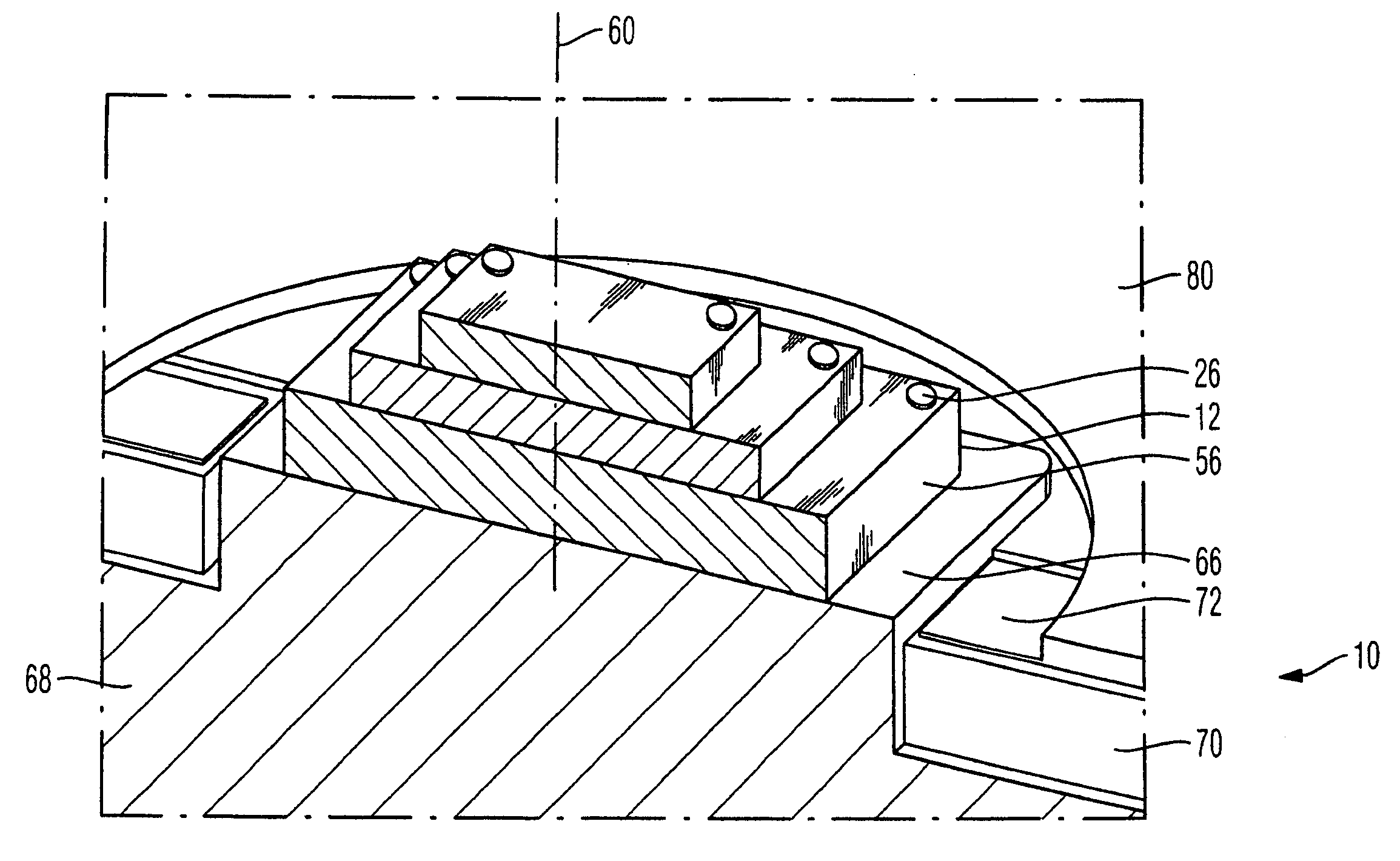

Tone plate for keyboard-type tone plate percussion instrument, tone plate-fabricating method, tone generator unit of tone plate percussion instrument, and keyboard-type percussion instrument

InactiveUS20090211428A1Increase freedomShorten the lengthStringed musical instrumentsPercussion musical instrumentsDegrees of freedomFront and back ends

A tone plate which makes it easy to reduce the entire length and width thereof, thus increasing the degree of freedom in design. The tone plate includes an antinode portion, front and rear ends, and first and second supporting holes which are located closer to the front and rear ends than to the antinode portion and at which a vibration node can be formed. There are provided first and second mass concentrating portions extending toward the front and rear ends from locations on a side close to the first and rear ends with respect to the supporting holes. First and second thinner portions are respectively provided between the antinode portion and the supporting holes. The tone plate vibrates to generate a musical tone of a specific tone pitch when struck with being supported at the supporting holes.

Owner:YAMAHA CORP

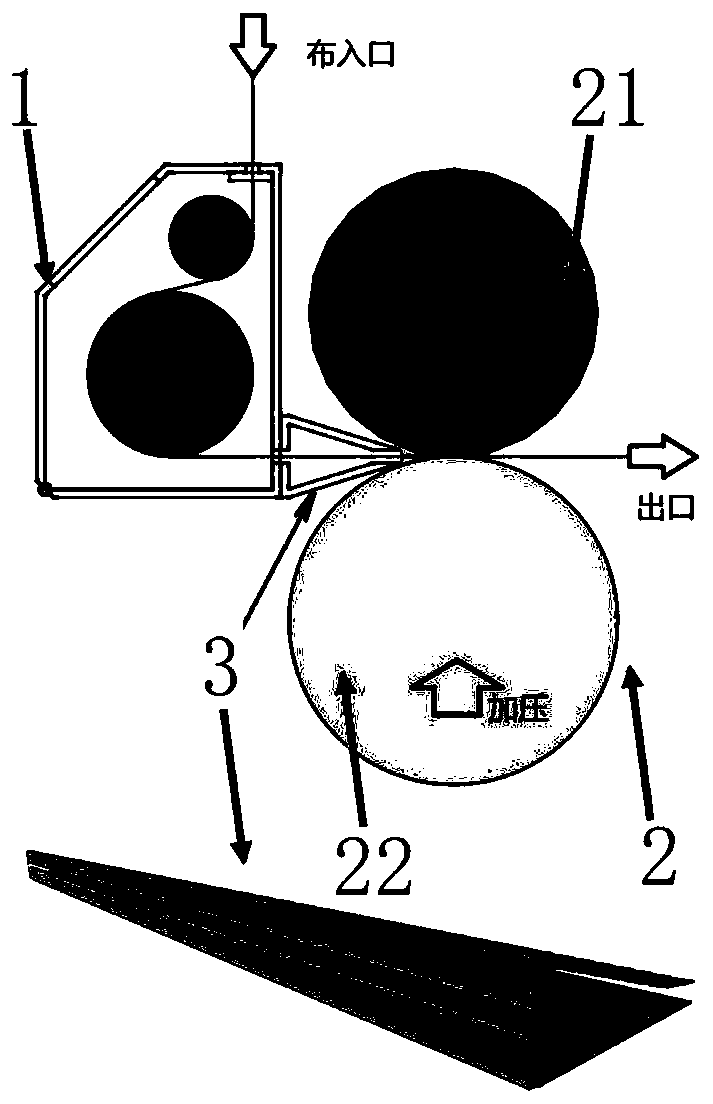

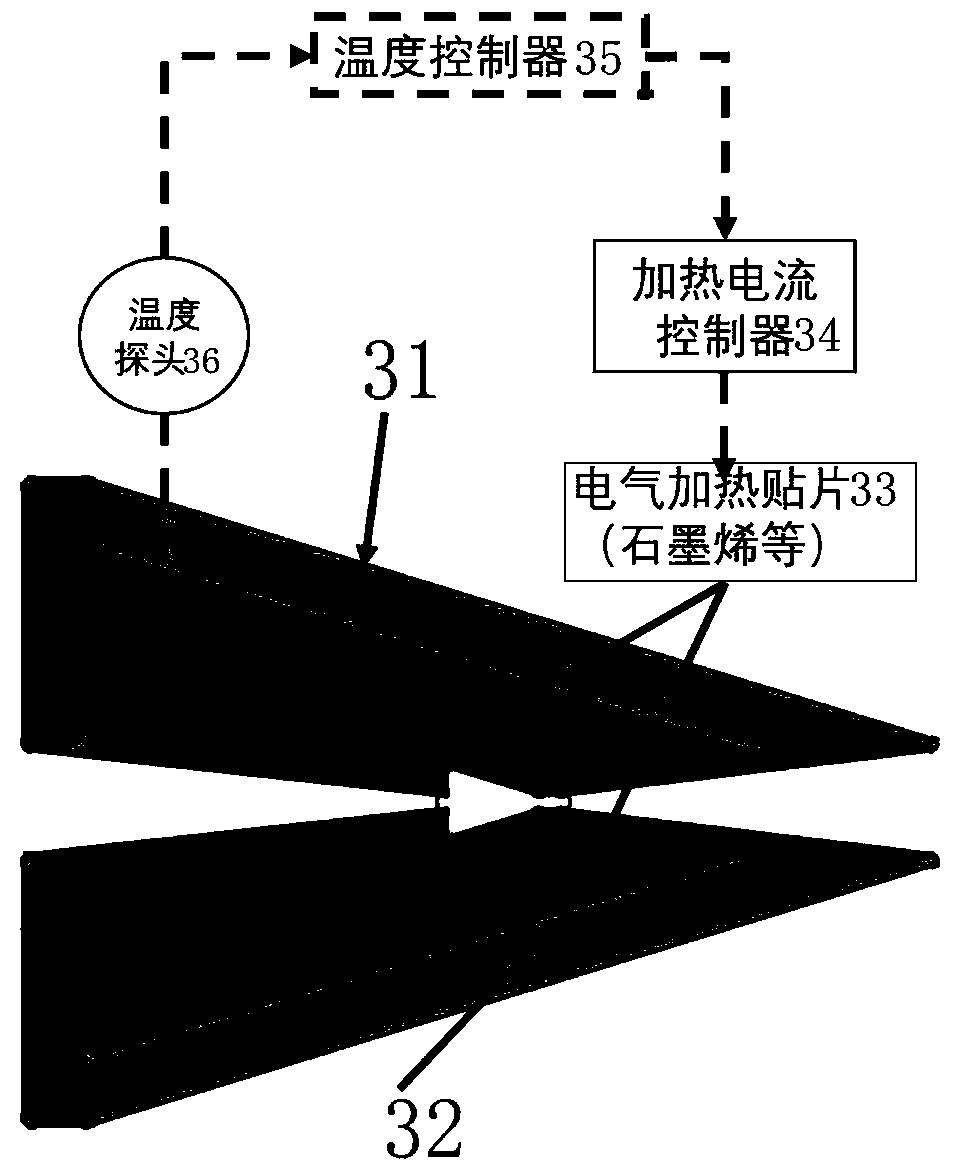

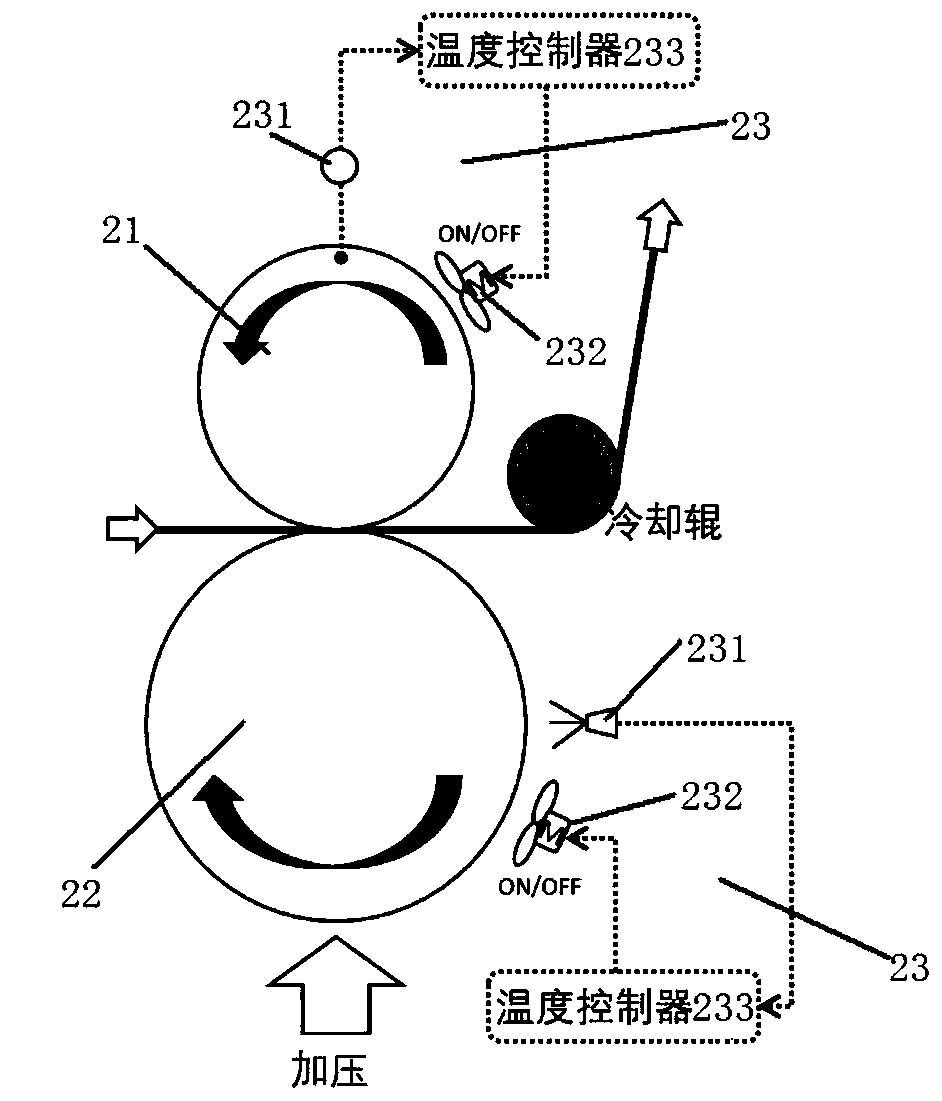

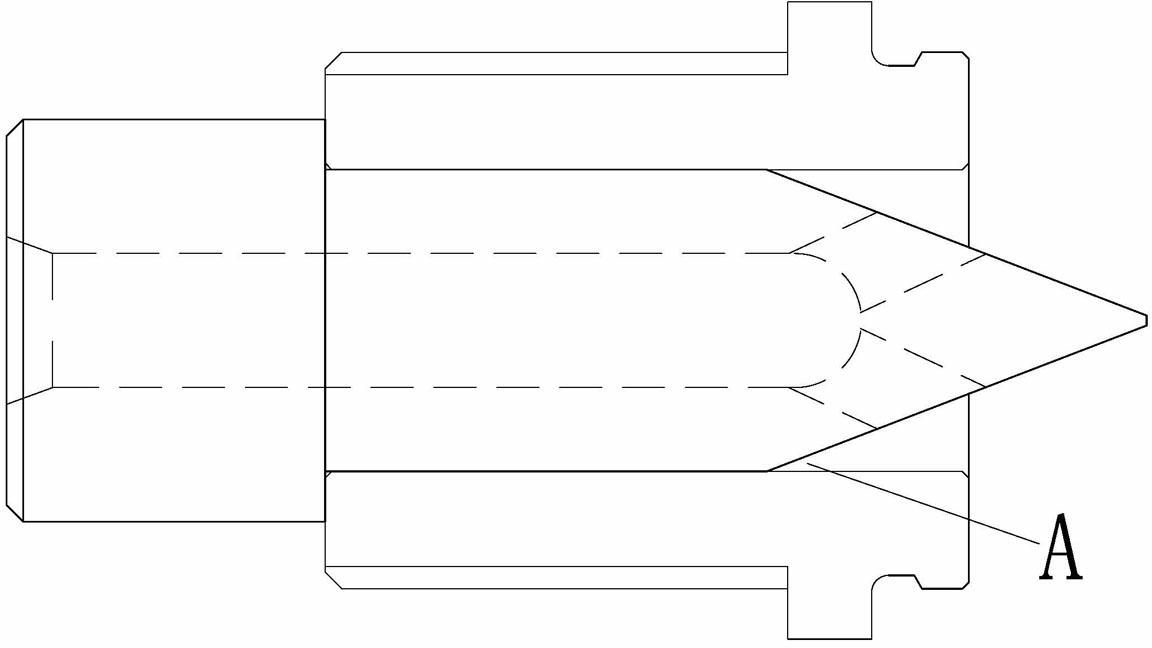

Fabric hot-pressing separation type calendaring processing technology

ActiveCN111575975AReduce energy consumptionImprove the feelTextile/flexible product manufactureTextile shapingProcess engineeringWoven fabric

The invention discloses a fabric hot-pressing separation type calendaring processing technology. A heating system and a point rolling system are included. The heating system is synchronous to the point rolling speed of the point rolling system, and fabric is heated before point rolling; and a fabric surface temperature keeping device is arranged between the heating system and the point rolling system, and fabric surface temperature maintaining is guaranteed. Hot-pressing separation special hot-pressing separation calendaring machine processing equipment is calendaring machine equipment for textile, non-woven fabrics, leather and the like, wherein the hot-pressing separation special hot-pressing separation calendaring machine processing equipment includes the independent heating system (including infrared heating, steam heating and heat conduction oil heating) and a point rolling device.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

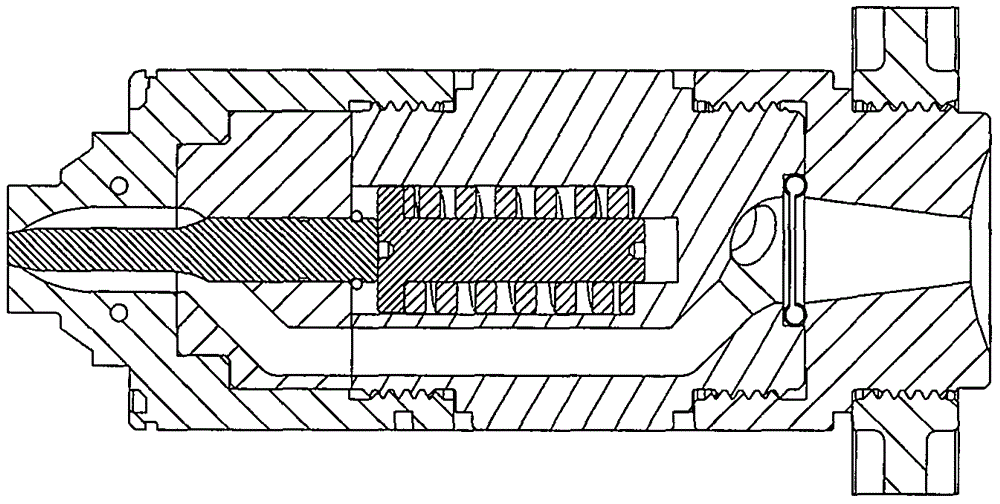

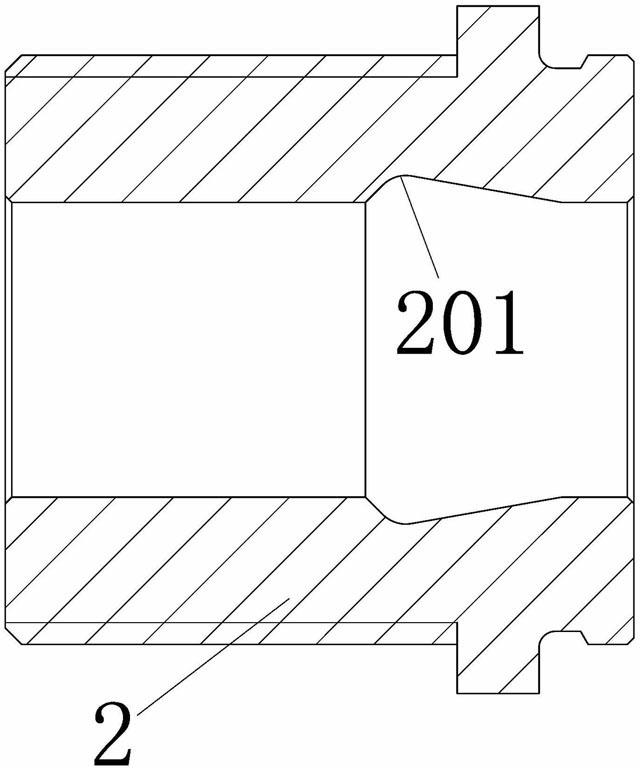

Hot runner hot nozzle assembly capable of directly changing color

The invention discloses a hot runner hot nozzle assembly capable of directly changing color, comprising a hot nozzle tip and an alien nut. The hot runner hot nozzle assembly is characterized in that the hot nozzle tip comprises a main body and a mouth tip, wherein the main body is provided with a straight runner; the nozzle tip is provided with plural sub-runners communicated with the straight runner; the outlets of the sub-runners are positioned on the root of the mouth tip; the surface of the mouth tips on the outlets is a concave annular transition arc surface; the alien nut is sheathed onthe hot nozzle tip; the front end of the inner cavity of the alien nut is matched with the main body of the hot nozzle tip; and the inner surface of the tail end is an inner annular inverse conical surface. The outlets of the sub-runners are positioned on the root of the mouth tip, the corresponding position surface is transited in concave annular transition arc surface, the reflecting countercurrent of fusion plastic washes the mouth tip surface, and thus the fusion plastic of the imperforate position of the mouth tip root part is taken away in time so as to thoroughly solve the problem of bank in the mouth tip; product color impurity is reduced, color changing operation is simple, quick and through, raw material waste is reduced, and production efficiency and product quality can be improved.

Owner:厦门博诺热流道科技有限公司

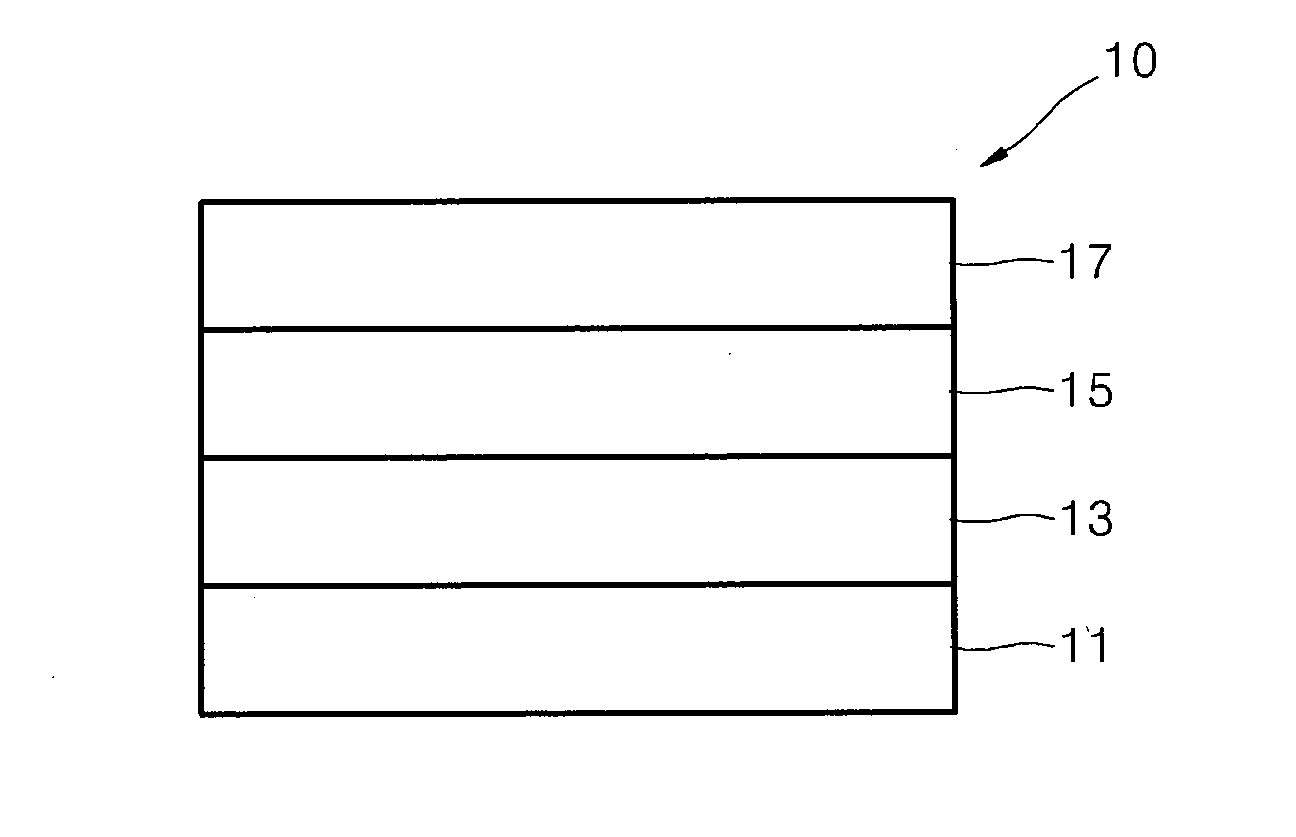

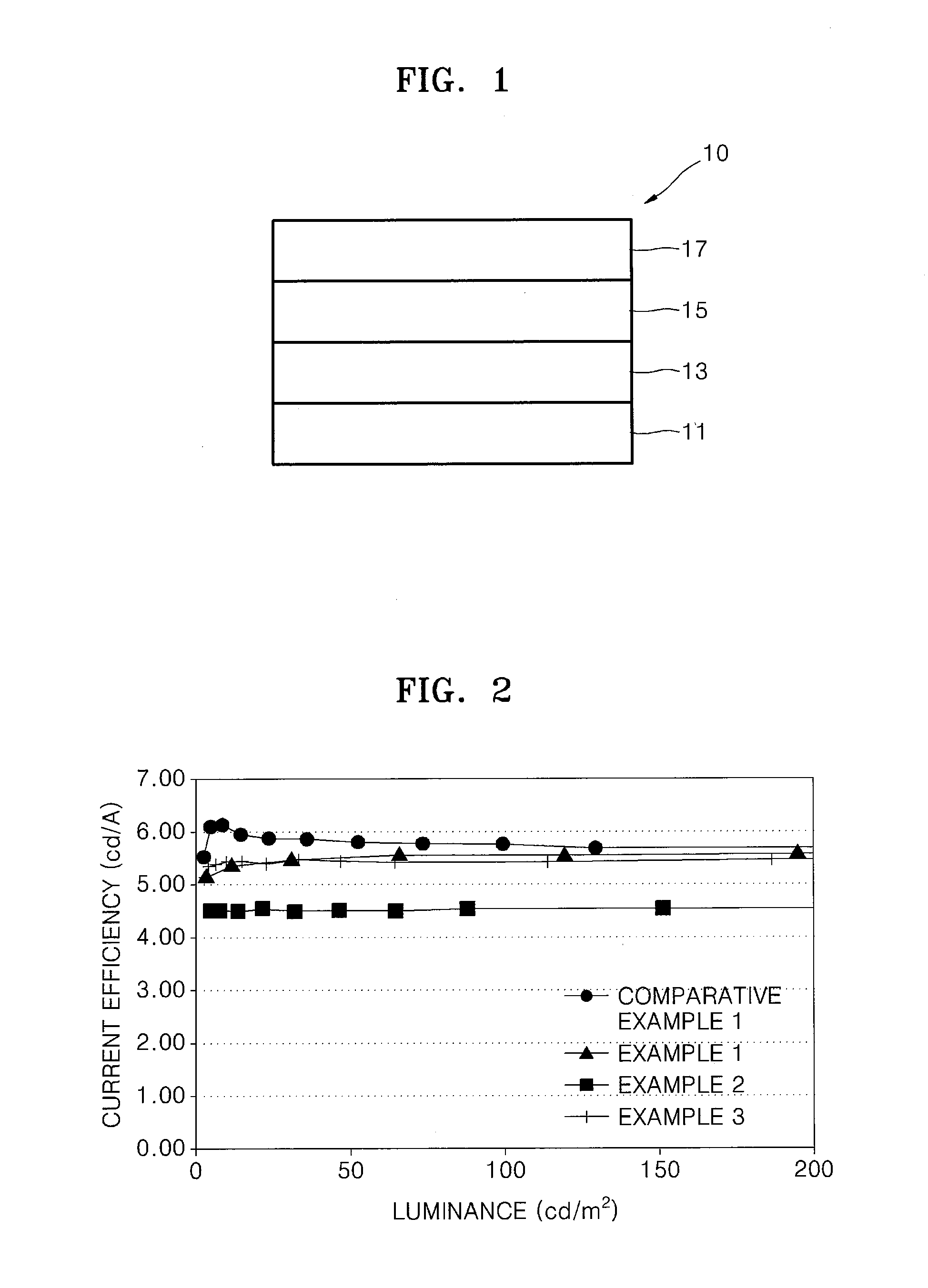

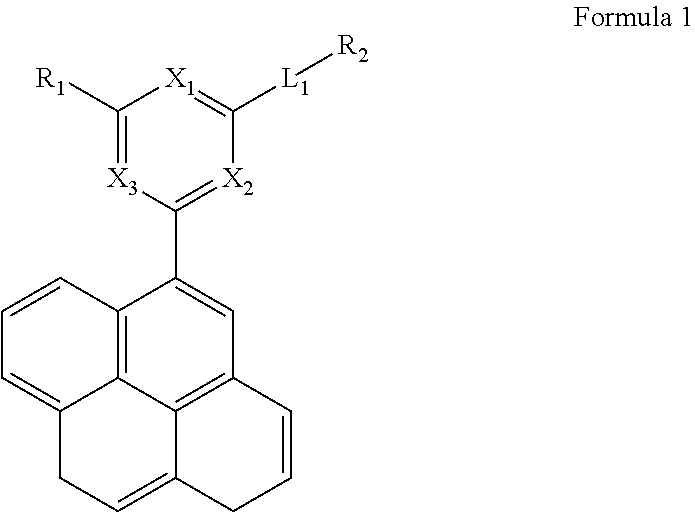

Condensed cyclic compound and organic light-emitting device including the same

InactiveUS20150263290A1Good matchingImprove color changeOrganic chemistrySolid-state devicesCyclic compoundPhotochemistry

A condensed cyclic compound is represented by Formula 1, and an organic light-emitting device includes the condensed cyclic compound.In Formula 1, X1, X2, X3, L1, R1, and R2 are already stated in the detailed description. An organic light-emitting device including an organic layer having the condensed cyclic compound has improved color change in a relatively low-gradation region.

Owner:SAMSUNG DISPLAY CO LTD

a plastic tile

InactiveCN105484432BBright colorNot easy to fadeRoof covering using tiles/slatesBlow moldingThermal insulation

The invention provides a plastic tile. The plastic tile is formed in one step according to a hollow blow molding and rotomolding process, is applied to the technical field of building materials and solves the problems that the conventional tile is heavy and frangible in transportation, undesirable in shock, pressure and cold resistance and thermal insulation and the like. The plastic tile comprises a platy body which is manufactured according to the hollow plastic technology, a sealed material storage cavity which is matched with the body in shape is formed in the body and can be filled with a material capable of enhancing the functional attributes of the tile, a feed opening is formed in the upper side surface of the body, communicated with the material storage cavity, and located on the edge of the body, and a detachable plug which can seal the feed opening is arranged in the feed opening. The plastic tile is relatively light in transportation, has the fire, cold and pressure resisting and thermal insulating effects, and can be recovered, thereby being low in energy consumption and environmentally friendly.

Owner:林红建

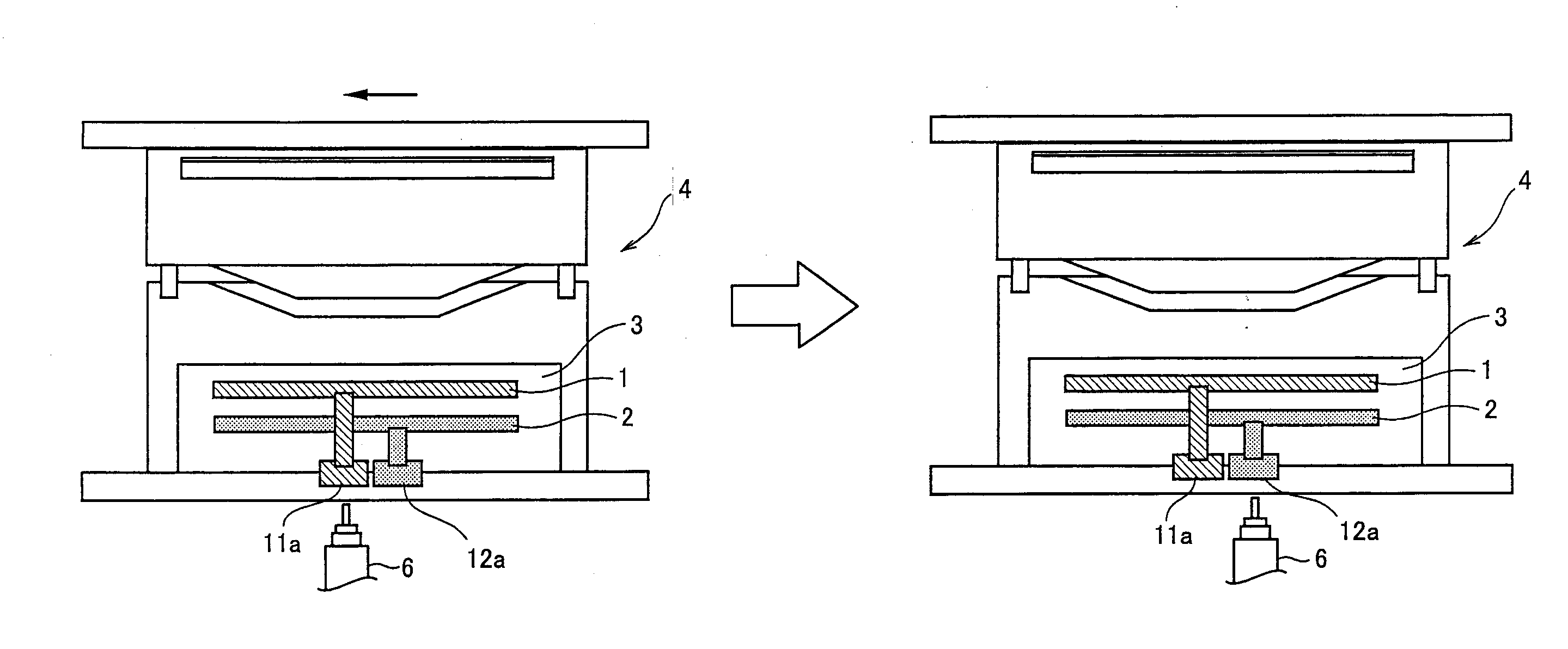

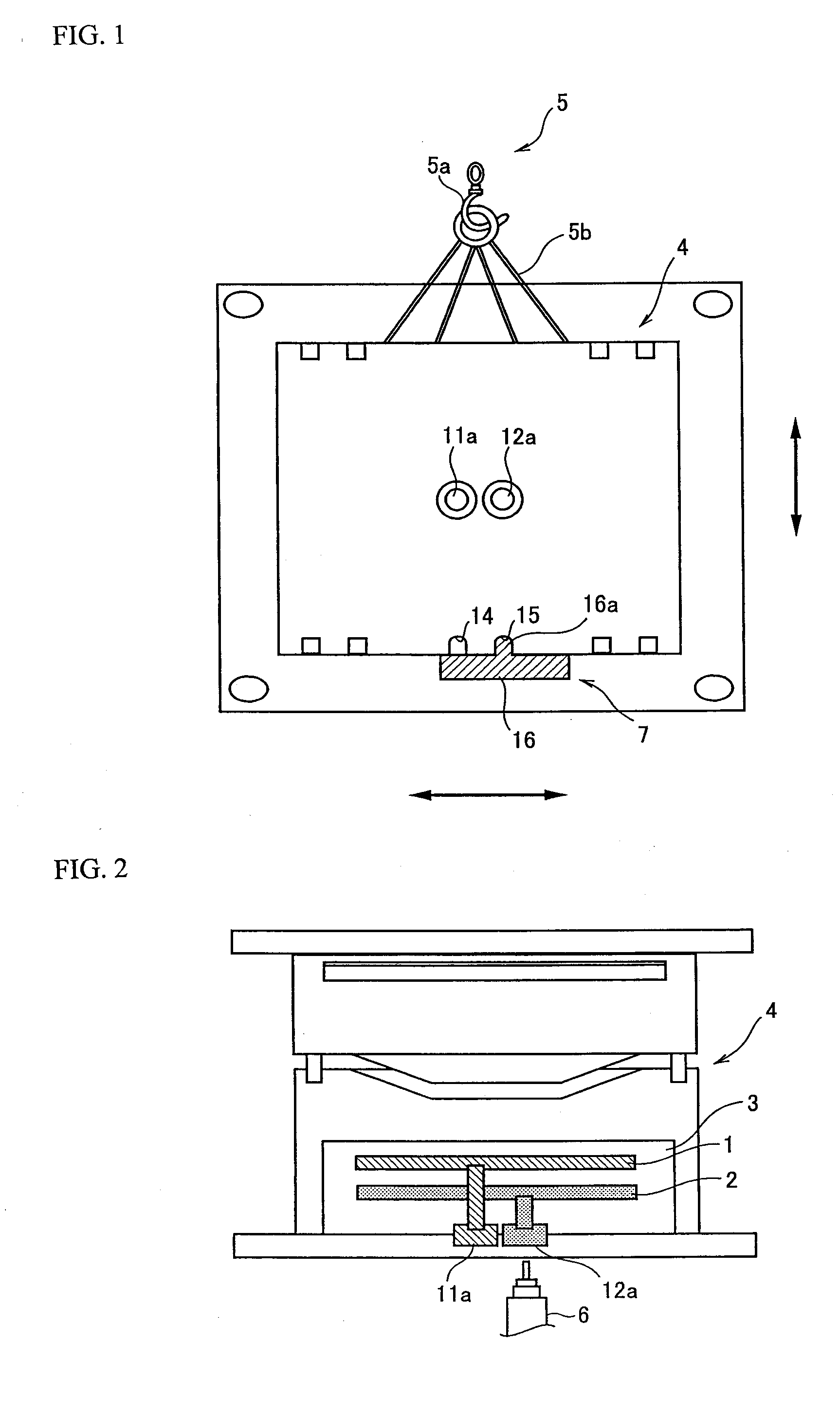

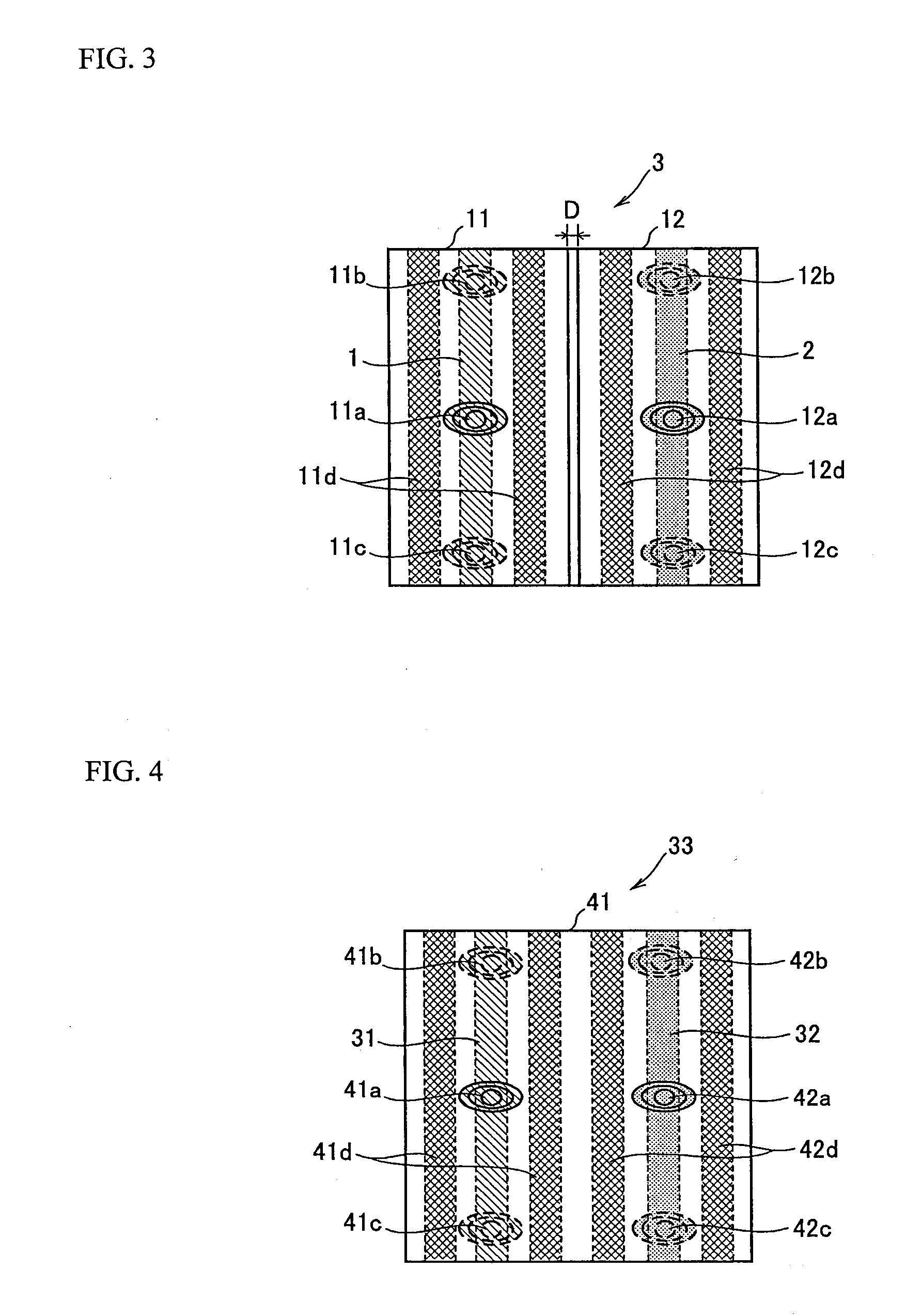

Method of and apparatus for changing colors of injection molding hot runner die

ActiveUS20070045900A1Short working hoursImprove color changeConfectionerySweetmeatsHot runnerHeat flow

A color changing apparatus of an injection molding hot runner die which is simple in construction and easily capable of changing colors for molding products without removing and replacing a hot runner. In the apparatus, a passage for supplying a melted resin to a molding die, a divided type hot runner block is provided with hot runners each for exclusive use of each of molding colors, sprues and nozzles being in communication with the hot runners. A moving device is provided for moving the molding die, which is united with the divided type hot runner block, along with the divided type hot runner block. A positioning device is adapted to place the molding die in position in a state where either of the sprues of the divided type hot runner block is moved by the moving device to a position opposed to an injection nozzle for injecting the melted resin.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com