Plastic wall plate

A plastic wallboard and plastic technology, applied in the direction of walls, building materials, building components, etc., can solve the problems of troublesome transportation and installation, difficult to recycle, and single use function, etc., to achieve easy transportation, good environmental protection, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

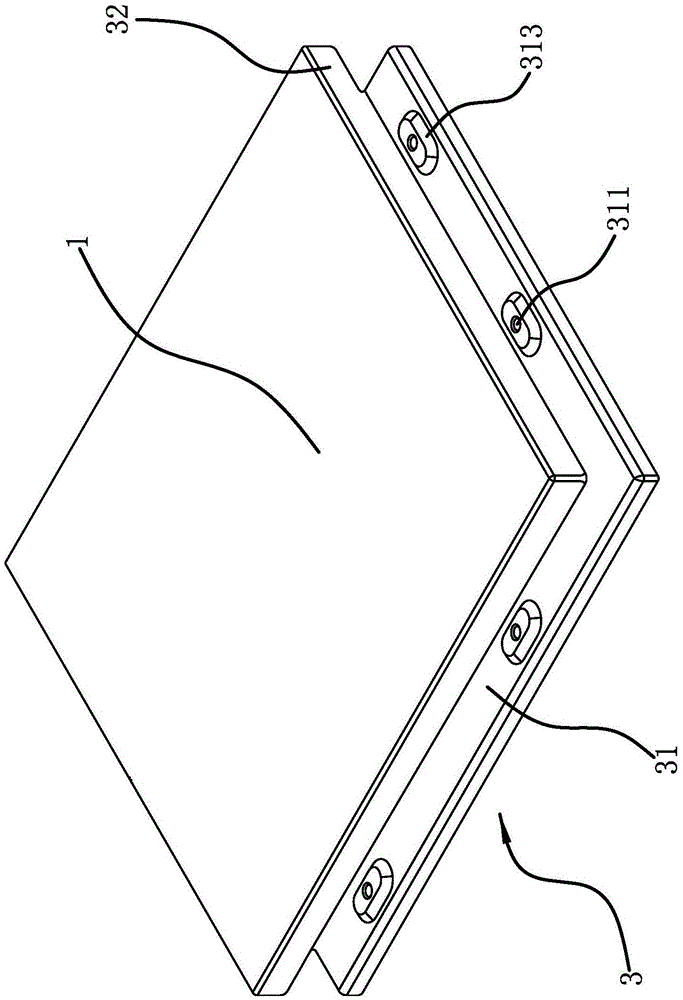

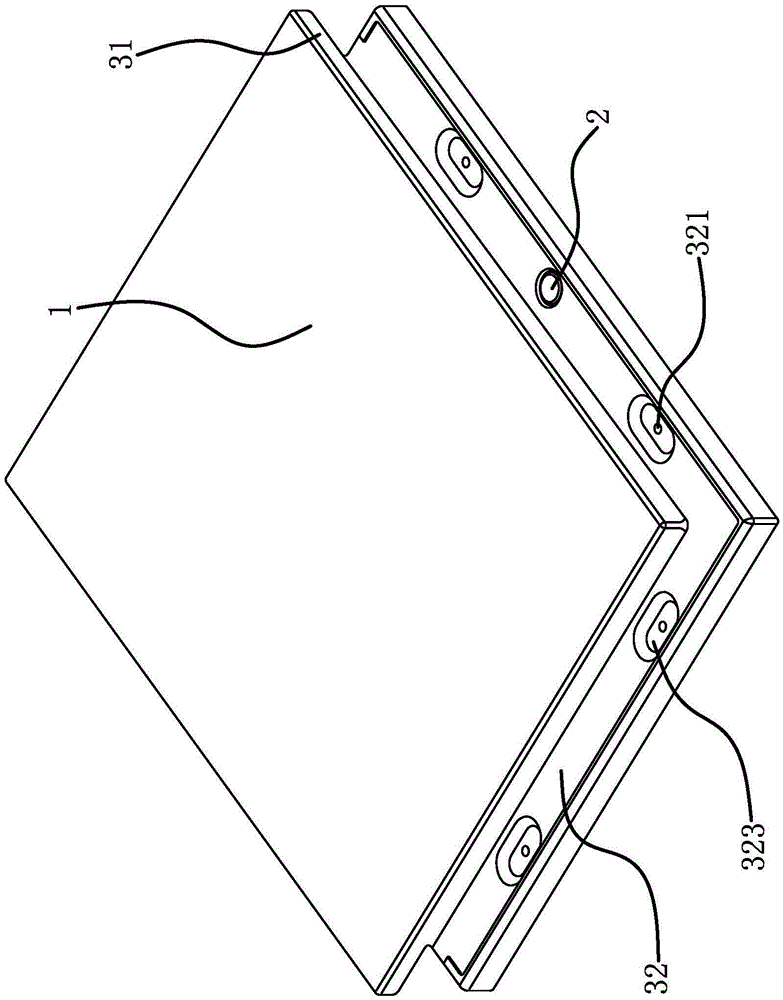

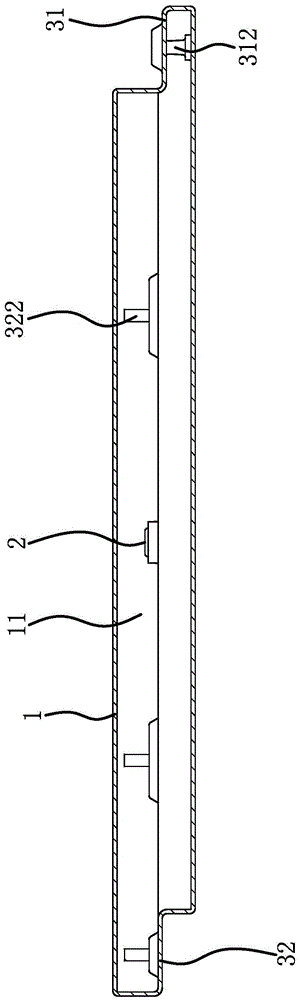

[0026] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a plastic wall panel includes a rectangular body 1, the body 1 has a sealed storage cavity 11, the storage cavity 11 is filled with materials that can increase the functional properties of the wall panel, and the shape of the storage cavity 11 is the same as The shape of the main body 1 is suitable. The main body 1 is provided with a feeding hole 12. The feeding hole 12 is communicated with the material storage cavity 11. For the plug 2, the body 1 is made of plastic, and the body 1 is further provided with a connecting structure 3 for connecting two adjacent bodies 1 together. The body 1 is rectangular and can be spliced block by block. When the adjacent bodies 1 are in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com