Manufacturing method of light building wallboard

A manufacturing method and construction technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of increased transportation costs, high installation and assembly costs, and low assembly efficiency, and achieve reduced transportation, installation, and assembly costs, simple manufacturing process, and easy assembly. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

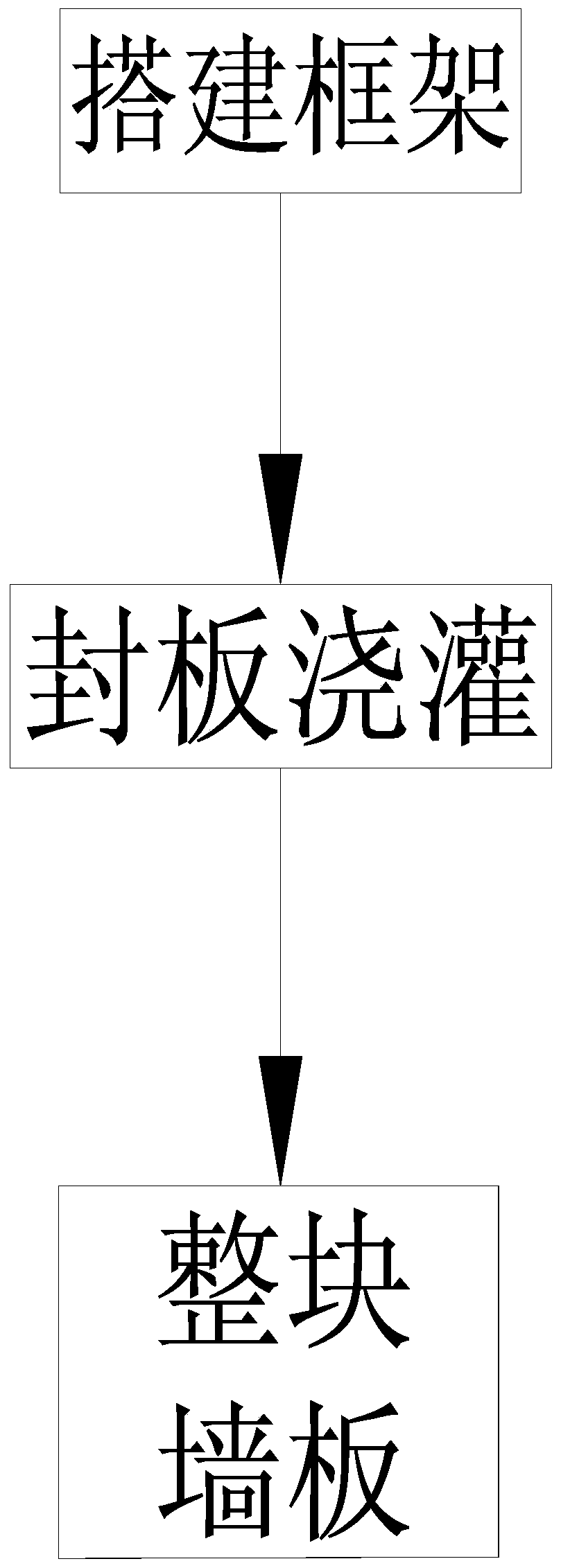

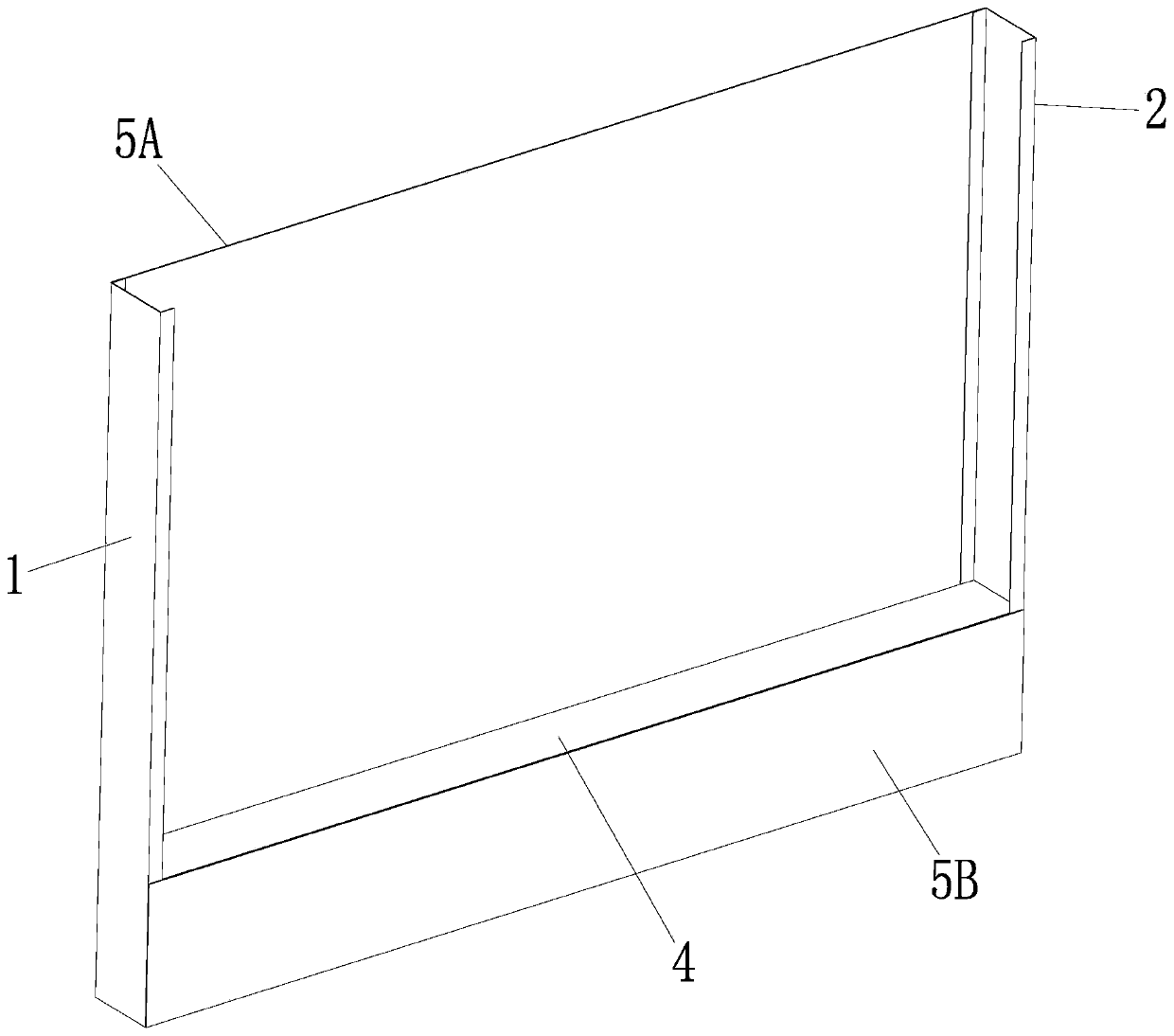

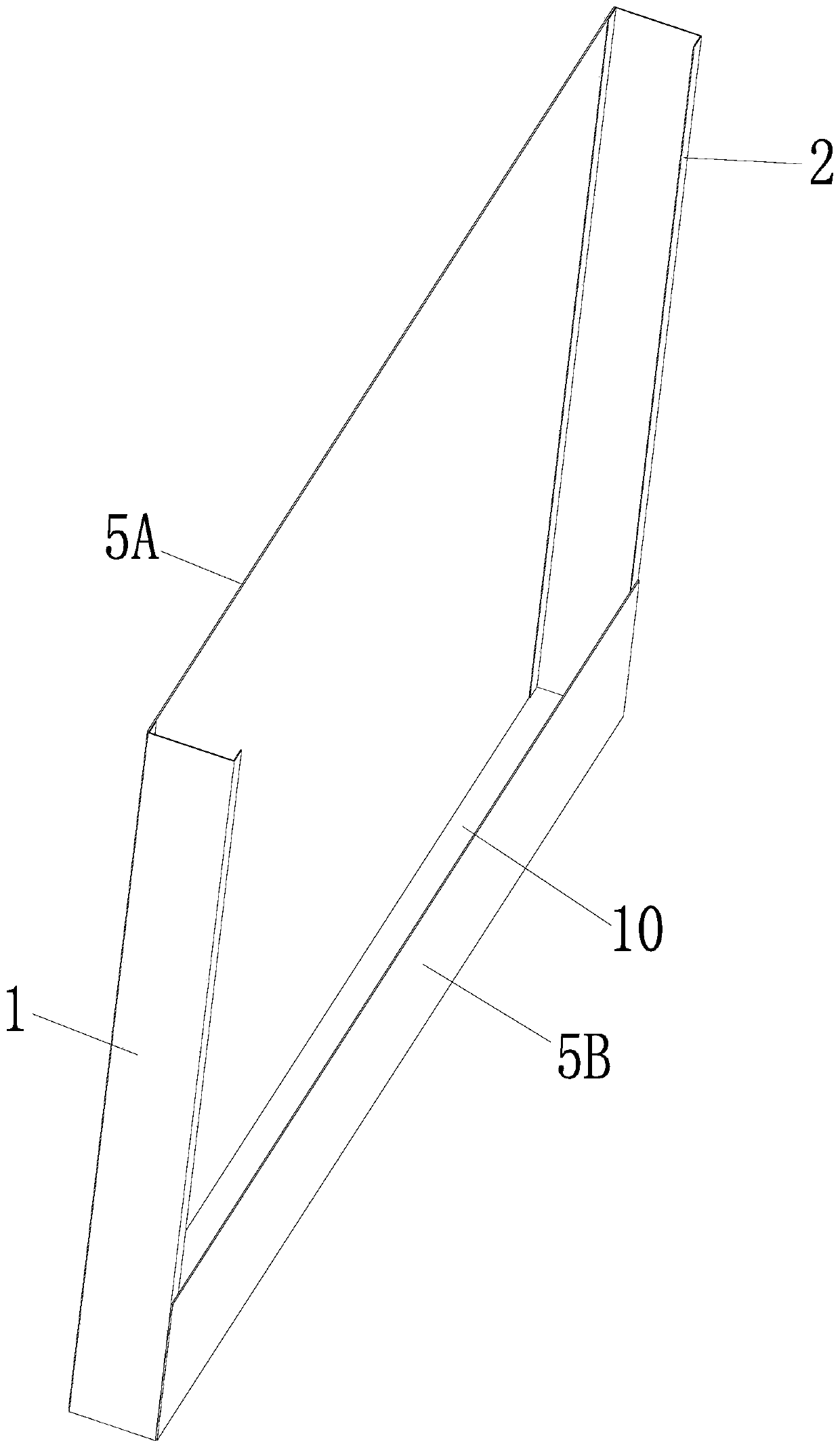

[0030] Such as Figure 1 to Figure 8 Shown, the manufacture method of a kind of lightweight building wallboard of the present invention is characterized in that: its manufacture method is finished as follows:

[0031] Step A: Build the frame: Install and connect the rear baffle 5A between the rear end of the left frame 1 and the rear end of the right frame 2. side wall;

[0032] Step B: Sealing and watering: install and connect the front baffle 5B between the front end of the left frame 1 and the front end of the right frame 2, the front baffle 5B has multiple pieces, the front baffle 5B, the rear baffle 5A, the left frame 1 and the The right frame 2 encloses a cavity 10, and the front baffle 5B is gradually encapsulated from the bottom to the top, and every time a front baffle 5B is packaged, the cavity 10 is poured with lightweight building foam material 4 and other lightweight building foam material 4 Solidification repackages the next front baffle plate 5B and pours the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com