Ultra-wide silk screen dot print film splicing method

A technology of wide screen and dots, applied in the field of ultra-wide screen dot printing film splicing, can solve the problems of difficult quality, waste of printing efficiency, and affecting appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] The film is static laser printing, the accuracy is controlled at 0.01%, the length*width is required to be 2799MM*2995MM, the coverage rate is 40% dot glazed glass, and the laser film splicing method realizes one-time printing. The specific method is:

[0020] 1. Take two 3000mm*1500mm laser film sheets with the same dot pattern 3. The seams are overlapped by the upper and lower films, and the dots of the upper and lower film sheets should be completely overlapped.

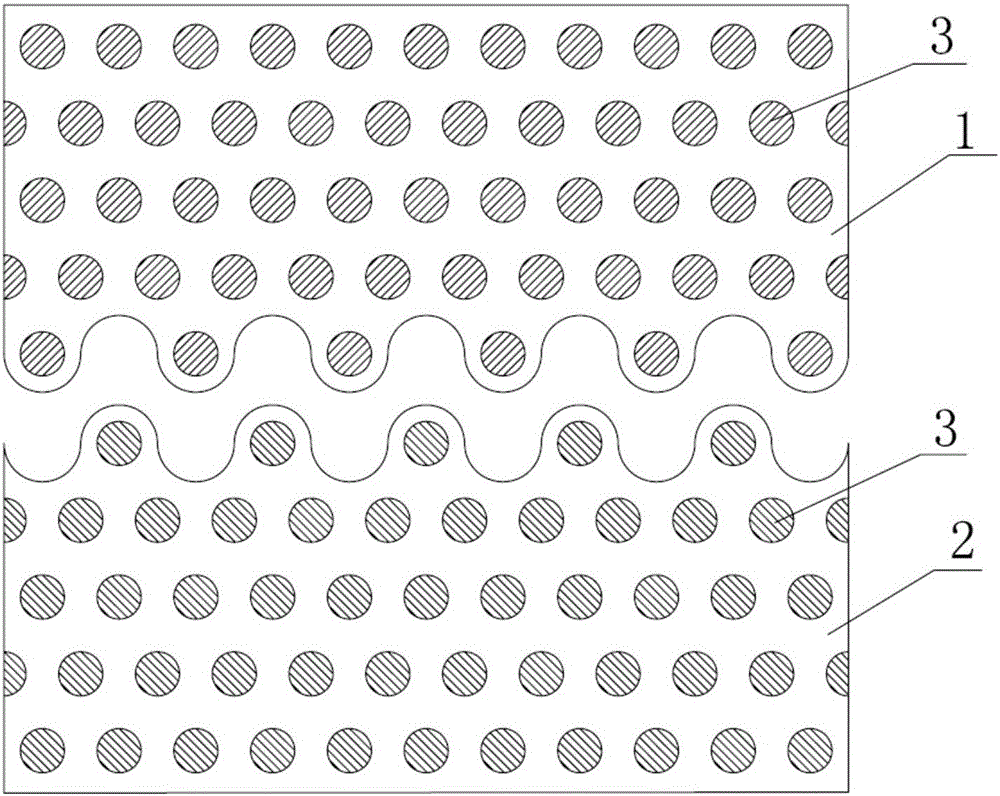

[0021] 2. Then use a special punching tool to remove the glaze spots on the overlapping parts of the film. The upper film sheet 1 is convex cut, and the next film sheet 2 is concave cut (such as figure 1 ).

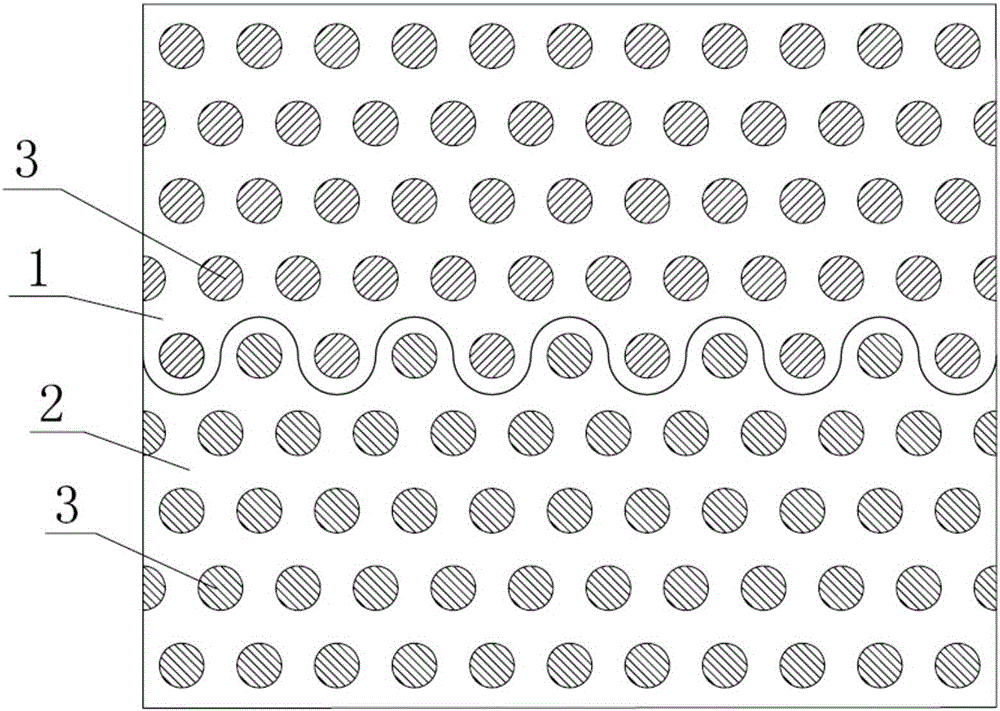

[0022] 3. After cutting, spread the two sheets of film on the pre-drying screen, and make the concave and convex sides approach horizontally (such as figure 2 ), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com