TFT-LCD display panel, manufacturing method thereof and display device

A display panel and display device technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of splicing seam width and poor visual effect, and achieve the effect of reducing the width, narrowing the splicing gap, and reducing the size of black borders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

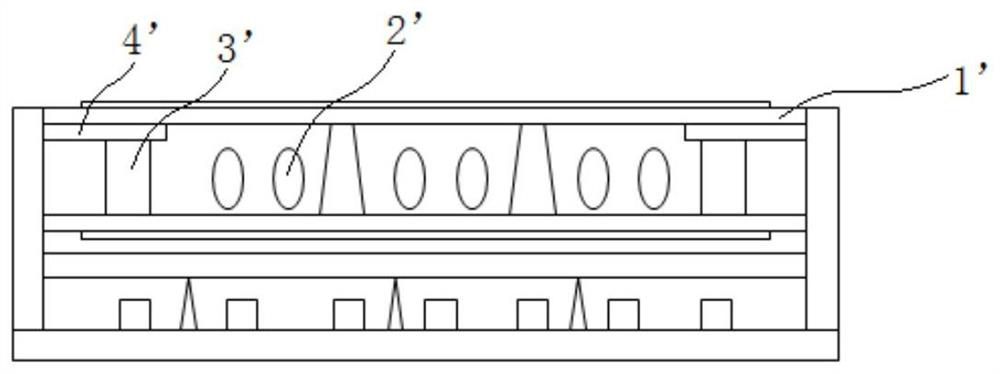

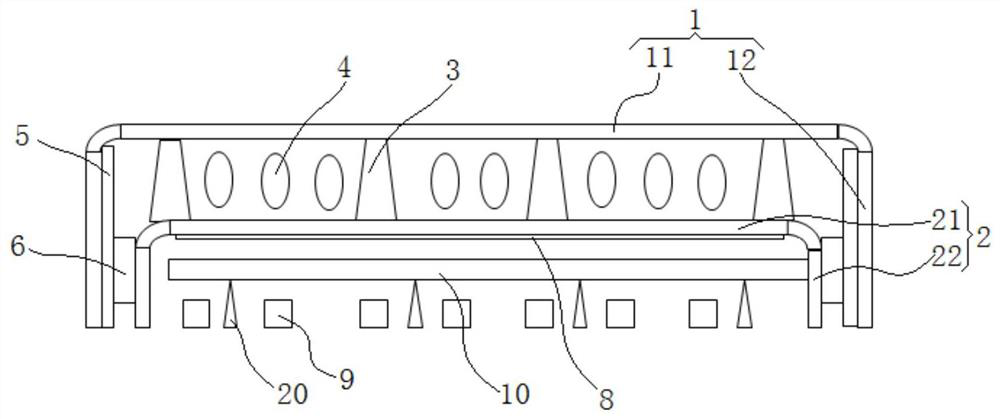

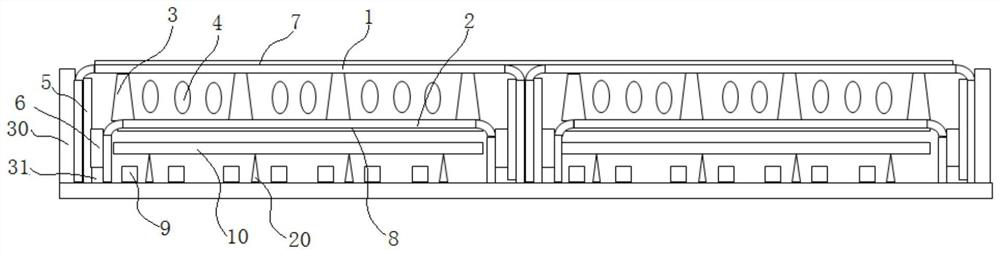

[0049] A TFT-LCD display panel according to a specific embodiment of the present invention will be described below with reference to the figures.

[0050] As shown in the figure, the TFT-LCD display panel includes two substrates, a spacer member 3, a liquid crystal element 4, a light shielding member 5, a plastic frame 6, a lower polarizer 8, a light emitting member 9, an optical film 10 and a support member 20 . The first substrate 1 includes a display portion 11 and a non-display portion 12 connected to both ends of the display portion 11, the first substrate 1 is a color filter substrate, the display portion 11 is the display area of the entire display panel, and the two non-display portions 12 define a A space for accommodating the second substrate 2 is provided. The second substrate 2 is an array substrate, and the second substrate 2 is located inside the first substrate 1. The second substrate 2 includes a first support portion 21 and a second support portion 22 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com