Back projection splicing display screen

A rear projection and display technology, which is applied in the field of rear projection splicing display screens, can solve problems such as image fragmentation and affect the overall effect of the image, and achieve the effect of reducing splicing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

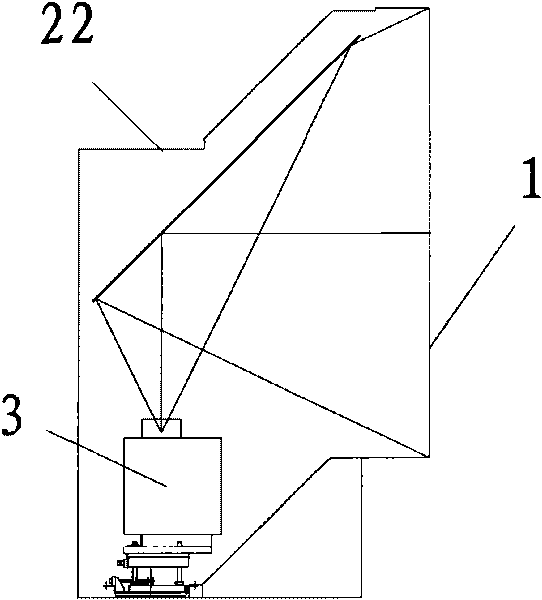

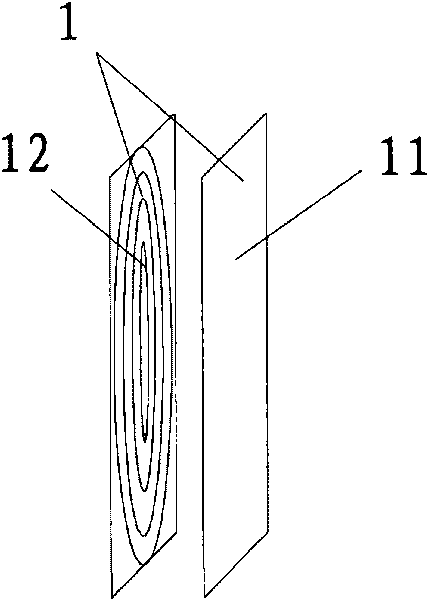

[0017] This example Figure 4 , the seamless rear projection splicing display screen is composed of 3×3 rear projection cabinets 2 spliced with each other, and each rear projection cabinet 2 includes a lens 12 for reversing the rear projection light, and also includes a rear projector and a The box body 22 in which the lens 12 is fixedly installed. For the convenience of adjustment, each rear projection cabinet 2 may also include an adjustment bracket for adjusting the light emitted by the rear projector. On the fronts of 3×3 rear projection cabinets 2 that are spliced together, a whole piece of curtain plate 11 is installed, and this whole piece of curtain plate 11 is close to the lens 12 fronts of 3×3 rear projection cabinets 2 that are spliced with each other. The seamless rear projection splicing display after installation is as follows Figure 5 shown.

[0018] Since a complete curtain panel 11 is used to correspond to multiple spliced rear projection cabinets ...

Embodiment 2

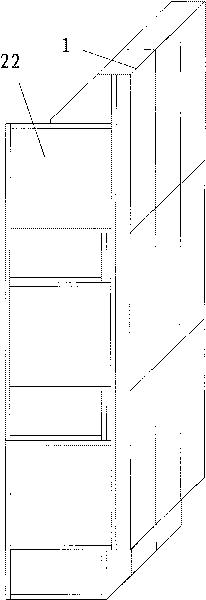

[0020] For larger display screens, it is difficult to use a complete screen panel 11, and the screen panel 11 can be made into a banner shape, such as Figure 6 , 7 As shown, three banner-shaped curtain panels 11 are spliced together, and each curtain panel 11 corresponds to three mutually spliced rear projection cabinets 2 . In this case, although there are splicing gaps between the individual screen panels 11, because one screen panel 11 is used to correspond to the three rear projection cabinets 2 that are spliced together, only three panels are used for the entire rear projection splicing display screen. Banner-shaped curtain panel 11, with figure 2 The number of seams is also greatly reduced compared to where there are only horizontal or vertical seams.

[0021] The above two examples:

[0022] The lens 12 generally refers to a threaded lens 12 , or is also called a Fresnel lens 12 .

[0023] The curtain plate 11 can be a simple scattering curtain, or an optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com