OLED (organic light emitting diode) display module and OLED spliced display screen with OLED display module

A technology for display modules and contact wires, applied in the field of organic light-emitting diode (OLED) display, which can solve problems such as affecting viewing effects, failure to display images, discontinuous screen images, etc., to reduce non-luminous areas, reduce splicing gaps, Optimize the effect of the display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

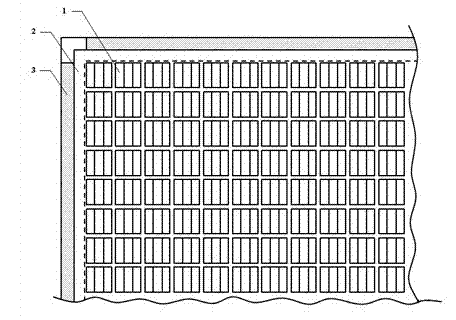

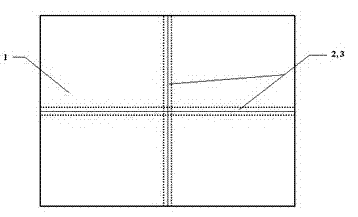

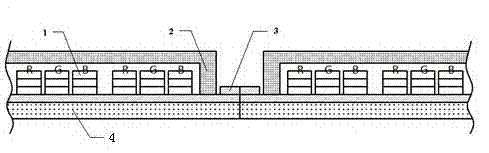

[0038] Such as Figure 4-7As shown, an OLED display module includes a substrate, an OLED structure for producing OLED light-emitting pixels, and an encapsulation layer for encapsulating the OLED structure. In the wiring area 6, contact wires 7 corresponding to the OLED light-emitting pixels are printed on the PCB substrate 5, and each contact wire 7 is connected to the OLED structure at the position of the corresponding OLED light-emitting pixel, and each contact wire 7 penetrates the PCB substrate 5 Connect to wiring area 6. In this embodiment, the PCB board is used as the substrate of the OLED display module, and the OLED light-emitting pixels are directly fabricated on the PCB substrate 5, and the contact wires 7 are circuit-wired on the PCB substrate 5 according to the distribution of the OLED display module light-emitting pixels, and The contact wire 7 leads through the PCB substrate 5 and is connected to the wiring area 6 on the back of the PCB substrate 5. By designing...

Embodiment 2

[0045] Such as Figure 10 As shown, the structure of Example 2 is similar to that of Example 1, the difference is that, in order to further reduce the non-luminous area of the OLED display module, the OLED structure is sealed by thin-film packaging. Specifically, the encapsulation layer is a wetting thin film layer 8, and the wetting thin film layer 8 is distributed on the front, each side of the OLED structure and between each OLED light-emitting pixel. During production, the liquid monomer is evaporated to directly infiltrate the thin film onto the OLED light-emitting pixels, and condense to the surface of the device to form a layer of high molecular polymer film, that is, the infiltrating film layer 8 . The present invention does not need to retain the sealing area 2 when the wetting film layer 8 is used for encapsulation, and only the light emitting area 1 is reserved when viewed from the direction of the light emitting surface of the OLED display module.

[0046] Such ...

Embodiment 3

[0049] Such as Figure 13 As shown, the structure of embodiment 3 is similar to the structure of embodiment 1, the difference is that in order to reduce the OLED display module sealing area 2 and ensure the simplicity and feasibility of the process, the embodiment 3 uses a glass cover plate 10 clamp Encapsulation method of sealing glue. Specifically, the encapsulation layer includes a sealing glue layer 9 spin-coated on the OLED structure and a glass cover 10 disposed on the sealing glue layer 9 . During production, the sealing glue is spin-coated on the OLED structure, and the sealing glue completely infiltrates the light-emitting area 1 of the device to form a sealing glue layer 9, and then the glass cover plate 10 is directly pressed on the device coated with the sealing glue to complete the sealing process of the device . This encapsulation method ensures that there is no gap between the OLED structure, the sealing glue layer 9 and the glass cover 10 , and they are tight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com