Resistance discharging fluorescent lamp of planar medium

A dielectric barrier discharge, fluorescent lamp technology, applied in discharge lamps, gas discharge lamps, fluorescent lamps, etc., to reduce brightness differences, ensure stability, and improve brightness uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

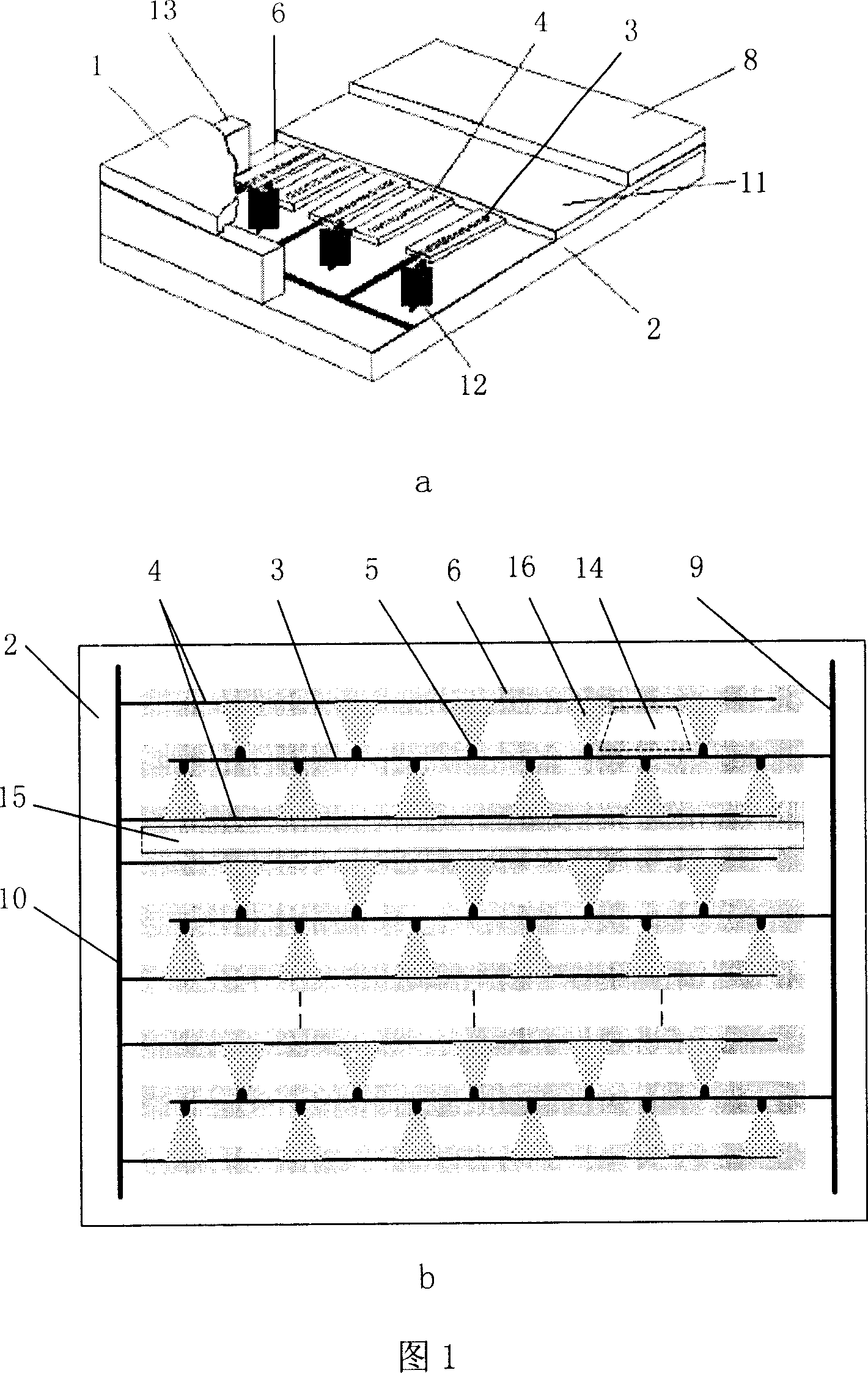

[0025] Fig. 1 is a schematic structural diagram of a planar dielectric barrier discharge fluorescent lamp in the prior art. It consists of a front glass substrate 1 and a rear glass substrate 2. The inner surface of the front glass substrate 1 is equipped with a phosphor layer, and the inner surface of the rear glass substrate 2 is equipped with two sets of electrodes—cathode and anode. The cathode is the X electrode 3. The anode is the Y electrode 4: the X electrode 3 and the Y electrode 4 are covered with a dielectric layer 6, and the surface of the dielectric layer 6 and the inner side of the rear glass substrate 2 not covered by the dielectric layer 6 are covered with a reflective layer 11. The reflective layer 11 The top is covered with a phosphor layer 8, and a certain distance is maintained between the front glass substrate 1 and the rear glass substrate 2 by support columns 12. After the two substrates are aligned, they are sealed together with low-melting point glass 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com