Fluorescent lamp having bulb whose end portion to which stem mount is welded, and a lighting apparatus having the fluorescent lamp

A technology for lighting devices and welding parts, which is applied in the direction of fluorescence, lighting devices, parts of lighting devices, etc., can solve the problems of reduced brightness in the end area and differences in bulbs, and achieve the effect of reducing the difference in brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The best embodiments for carrying out the present invention are described below using examples. Note that the embodiments described hereinafter are only examples for explaining the structure, function and effect of the present invention, so the present invention is by no means limited to the following embodiments as long as it does not depart from the scope of essential characteristics of the present invention.

[0029] 1. Structure of fluorescent lamp 1

[0030] Reference to the structure of the fluorescent lamp 1 belonging to the embodiment of the present invention figure 2 describe.

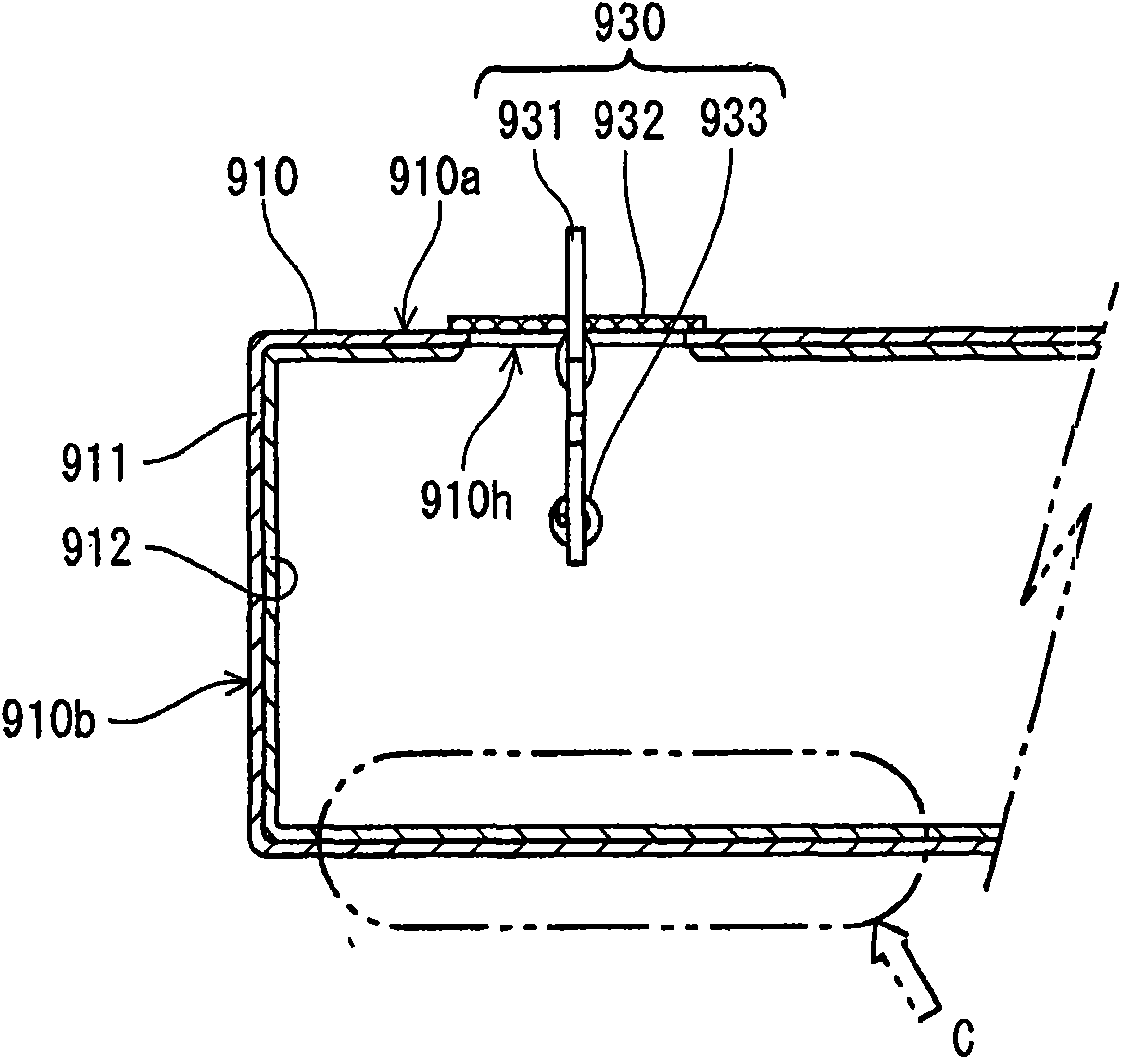

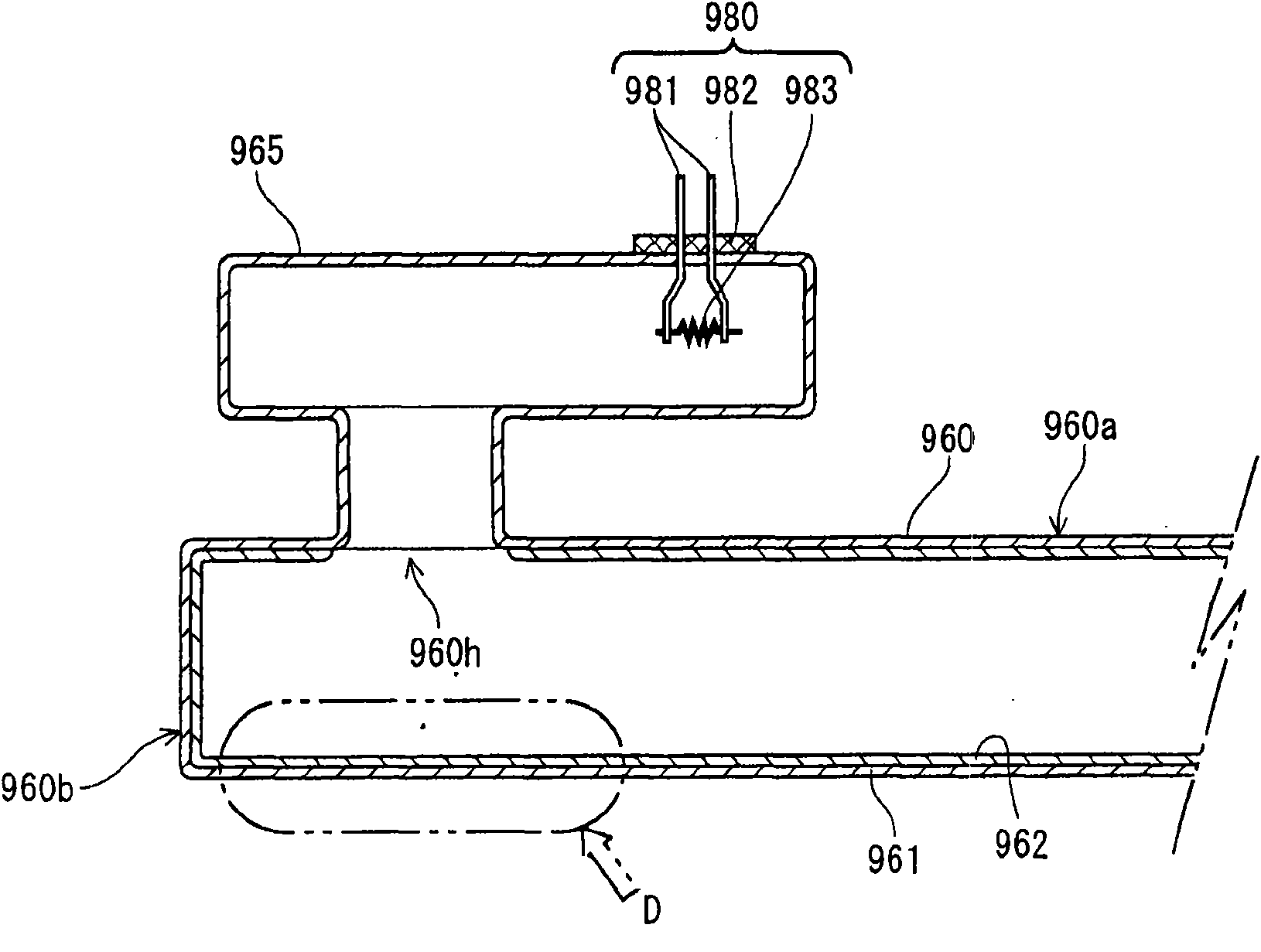

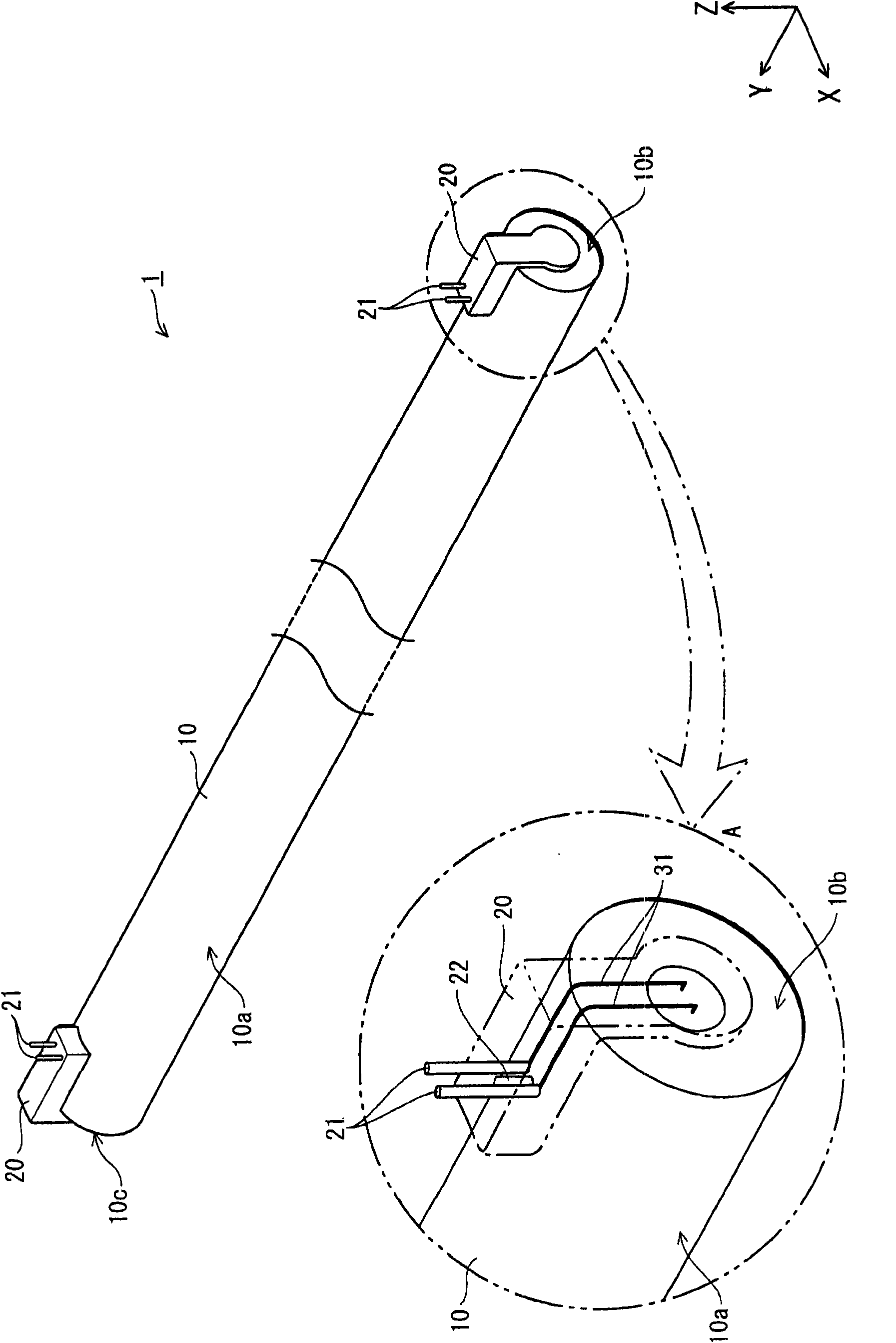

[0031] like figure 2 As shown, the fluorescent lamp 1 pertaining to the embodiment has a cylindrical glass bulb 10 whose tube axis is in the Y-axis direction and a base is provided at each end portion of the bulb 10 in the Y-axis direction. The base 20 at each end portion has two base pins 21 extending outward in the Z-direction intersecting the tube axis (Y-axis) of the glass bulb 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com