Device for forming isolated ribs on screen of plane display device

A technology for flat panel displays and substrates, which is applied in the directions of devices for coating liquids on surfaces, jetting devices, liquid jetting devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]

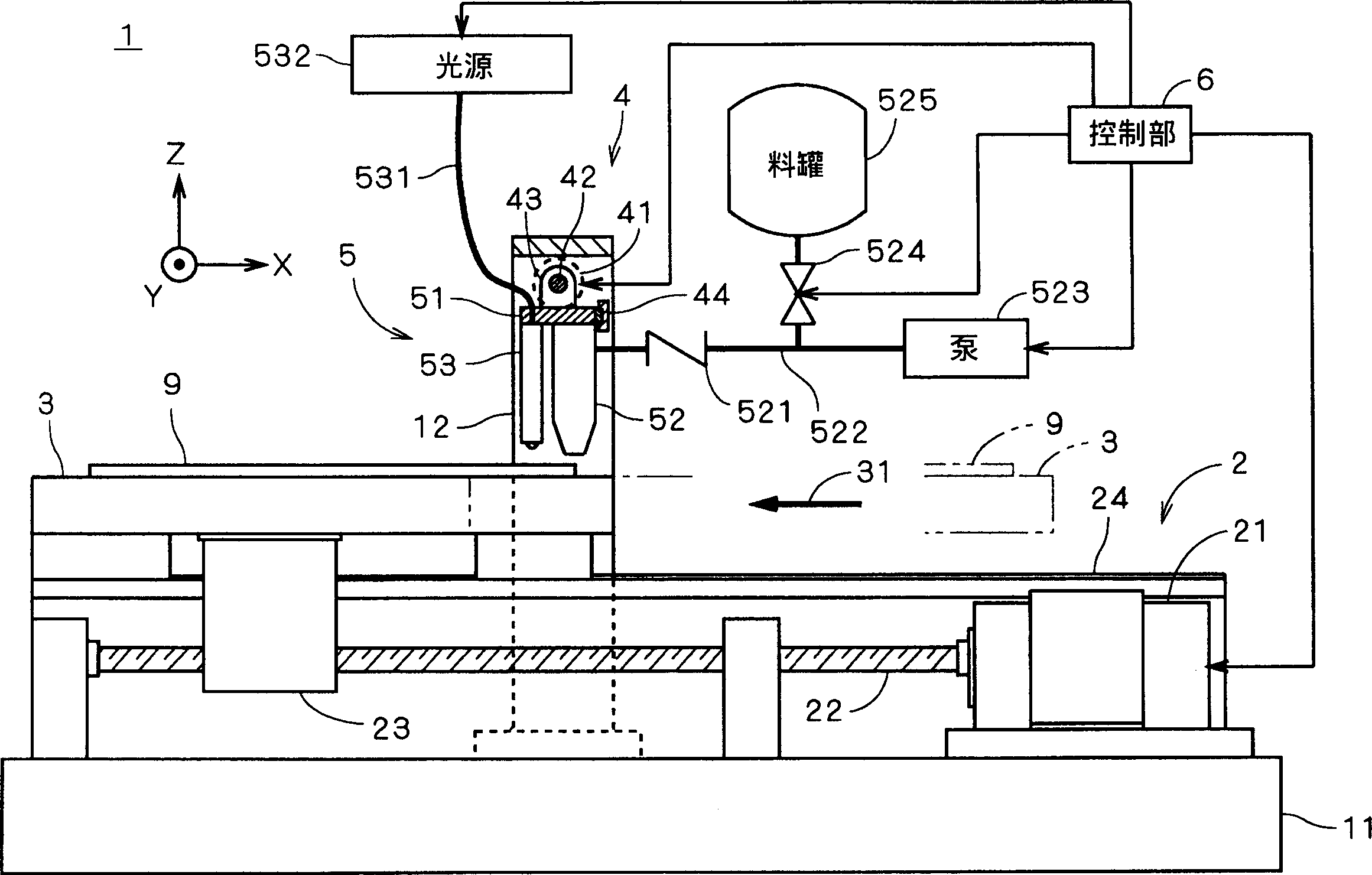

[0028] figure 1 is a view schematically showing the structure of the isolation rib forming device 1 according to the first preferred embodiment. The isolation rib forming device 1 is a device for forming isolation ribs on a glass substrate (called "substrate") 9 of a plasma display, and the substrate 9 on which the isolation ribs are formed becomes a screen plate (usually " Rear panel"), which is a sub-assembly of the plasma display.

[0029] In the isolation rib forming device 1, a platform transfer mechanism 2 is provided on the base 11, and the platform 3 supporting the substrate 9 can pass through the platform transfer mechanism 2 along the figure 1 to move in the X direction. The frame 12 is mounted on the base 11 across the platform 3 , and the head 5 is connected to the frame 12 via the swing mechanism 4 .

[0030] The platform transfer mechanism 2 has a structure in which a ball screw 22 is connected to a motor 21 and fitted into a nut 23 fixed on the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com