Method for producing copper alloy contact wire with excellent comprehensive performance

A comprehensive performance, copper alloy technology, used in cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as brittleness of contact wires, and achieve the effects of good plasticity, improved grain size and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

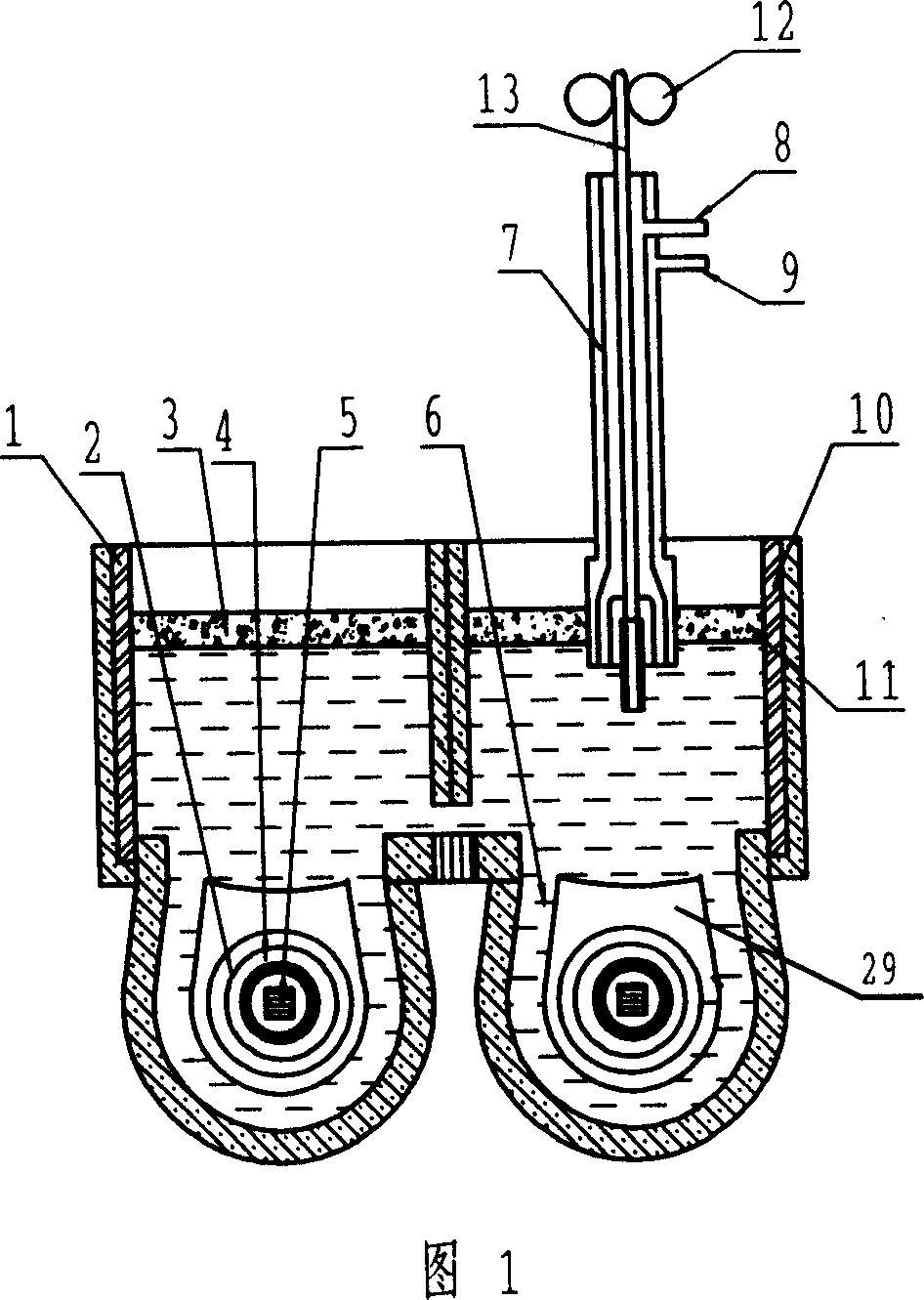

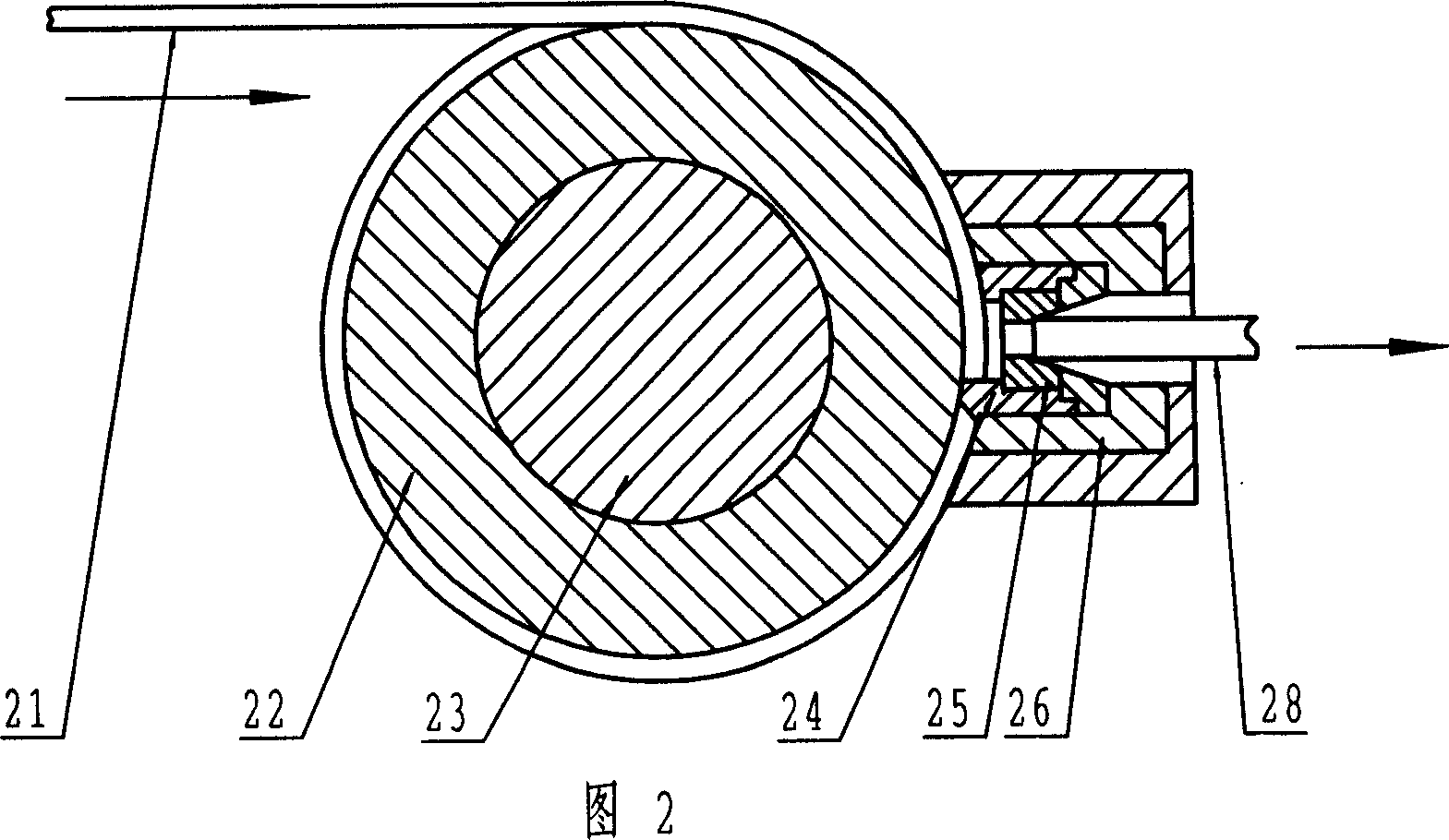

Image

Examples

Embodiment Construction

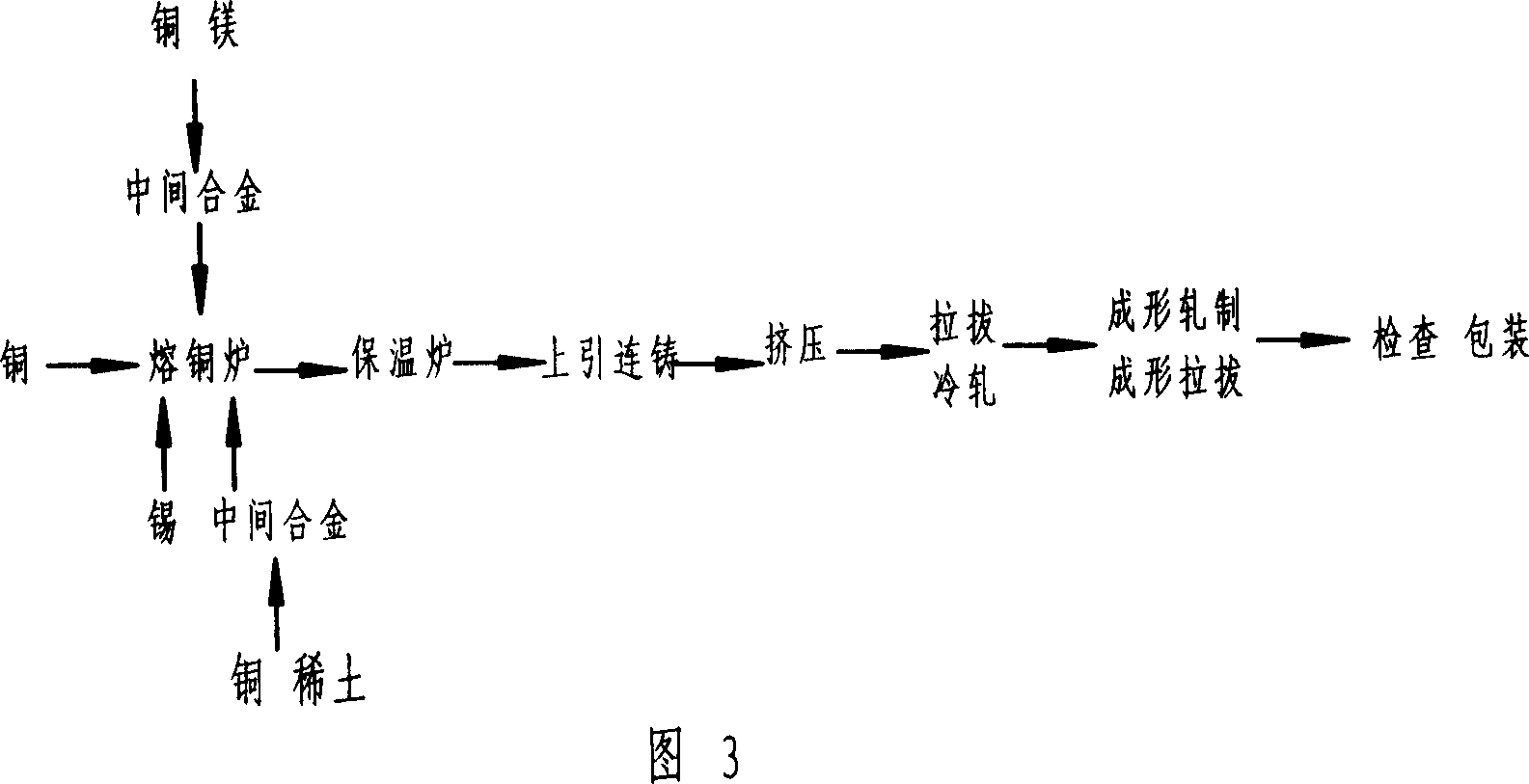

[0022] The contact wire raw material of the method of the present invention is a ternary copper alloy in which a small amount of magnesium and tin are added to a copper matrix or a quaternary copper alloy in which a small amount of magnesium, tin and rare earth elements are added. Among them, melting magnesium and tin into copper can form a solid solution with copper, aggravate lattice distortion, and play a composite strengthening role. Adding rare earth elements can not only refine grains, increase strength, eliminate or reduce composition segregation, but also improve the electrical conductivity of the alloy. By strictly controlling the addition amount and ratio of magnesium, tin, and rare earth elements, it is possible to improve the strength and electrical conductivity of the material, and at the same time make the alloy material have a high toughness index. Tests have shown that the strength of the above-mentioned ternary or quaternary alloys after upward continuous cast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com