Highly wear resistant copper silver alloy contact wire and production method thereof

A copper-silver alloy, production method technology, applied in metal/alloy conductors, electrical components, circuits, etc., can solve the problems affecting the service life of electrified railway catenary, etc., to ensure strength and electrical conductivity, improve wear resistance, purify Matrix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

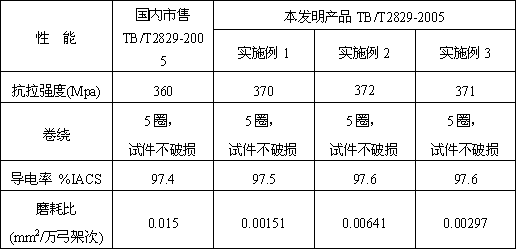

Examples

Embodiment 1

[0025] Example 1: Production of CTAH120 high wear-resistant copper-silver alloy contact wire

[0026] Take 99.895kg copper cathode, 0.09kg silver ingot, 0.006kg indium and 0.009kg tellurium with copper content> 99.95% (weight percentage), place them in a vacuum melting furnace, heat to 1050~1200℃, and smelt them into copper-silver alloy ingots. The copper-silver alloy ingot is smelted into a copper-silver alloy liquid using a power frequency furnace with a heating temperature of 1050~1200℃, the crystallizer is directly extended into the copper-silver alloy liquid, and the copper-silver alloy liquid is topped by the method of upward continuous casting. The copper-silver alloy rod is made by continuous casting. Charcoal is used to insulate oxygen during upward continuous casting, and the water is cooled by a jacket.

[0027] The copper-silver alloy rod is continuously extruded, and then rolled by a multi-roll continuous rolling mill to produce a copper-silver alloy rod that meets the...

Embodiment 2

[0030] Example 2: Production of CTAH85 high wear-resistant copper-silver alloy contact wire

[0031] Take 99.895 kg of copper cathode, 0.092 Kg of silver ingot, 0.005 kg of indium and 0.008 kg of tellurium with copper content> 99.95% (weight percentage), place them in a vacuum melting furnace, heat to 1050~1200℃, and smelt them into copper-silver alloy ingots. The copper-silver alloy ingot is smelted into a copper-silver alloy liquid using a power frequency furnace with a heating temperature of 1050~1200℃, the crystallizer is directly extended into the copper-silver alloy liquid, and the copper-silver alloy liquid is topped by the method of upward continuous casting. The copper-silver alloy rod is made by continuous casting. Charcoal is used to insulate oxygen during upward continuous casting, and the water is cooled by a jacket.

[0032] The copper-silver alloy rod is continuously extruded, and then rolled by a multi-roll continuous rolling mill to produce a copper-silver alloy ro...

Embodiment 3

[0035] Example 3: Production of CTAH150 high wear-resistant copper-silver alloy contact wire

[0036] Take 99.902 kg of copper cathode, 0.085 Kg of silver ingot, 0.005 kg of indium and 0.008 kg of tellurium with copper content> 99.95% (weight percentage), place them in a vacuum melting furnace and heat to 1050~1200°C to smelt them into copper-silver alloy ingots. The copper-silver alloy ingot is smelted into a copper-silver alloy liquid using a power frequency furnace with a heating temperature of 1050~1200℃, the crystallizer is directly extended into the copper-silver alloy liquid, and the copper-silver alloy liquid is topped by the method of upward continuous casting. The copper-silver alloy rod is made by continuous casting. Charcoal is used to insulate oxygen during upward continuous casting, and the water is cooled by a jacket.

[0037] The copper-silver alloy rod is continuously extruded, and then rolled by a multi-roll continuous rolling mill to produce a copper-silver alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com