Metal-based cable-like distributed optical fiber sensor

A distributed sensor and distributed optical fiber technology, applied in the field of sensors, can solve the problems of fiber optic sensor application limitations, cable body monitoring difficulties, etc., and achieve the effects of improving survival rate and sensitivity, improving timeliness, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

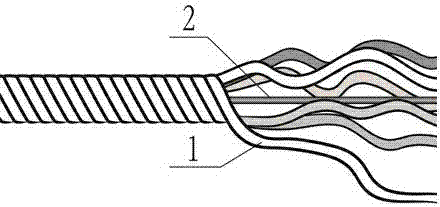

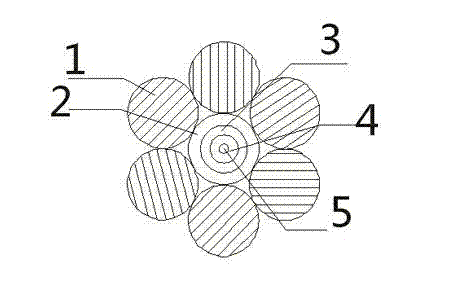

[0024] The metal cord-like material has a certain strength and meets certain requirements of ductility, deformability, machinability and corrosion resistance. The metal wires are steel wires, or metal wires made of metals such as copper, aluminum, and stainless steel. As shown in the figure: 1 steel wire bundle, 2 sheathed optical fiber, 3 coating layer, 4 cladding layer, 5 optical fiber core. Its implementation process is:

[0025] (1) Preparation of sensing fiber core

[0026] The sensing fiber core used in the present invention is common single-mode or multimode fiber core, tight package structure, and its diameter is 1 / 3 of the desired cable diameter, or slightly larger, so that can guarantee internal fiber core and The outer metal wires are in close contact and deform simultaneously. The outer cladding of the optical fiber has a certain degree of elasticity, which can buffer the external pressure and prevent the core from being squeezed and damaged during the strand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com