Intelligent pantograph device for trolley bus and using method thereof

A trolleybus and pantograph technology, applied in electric vehicle charging technology, electric vehicles, collectors, etc., can solve the problem that pantographs and contact wires cannot be automatically connected, and achieve high feasibility, cost saving, The effect of high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

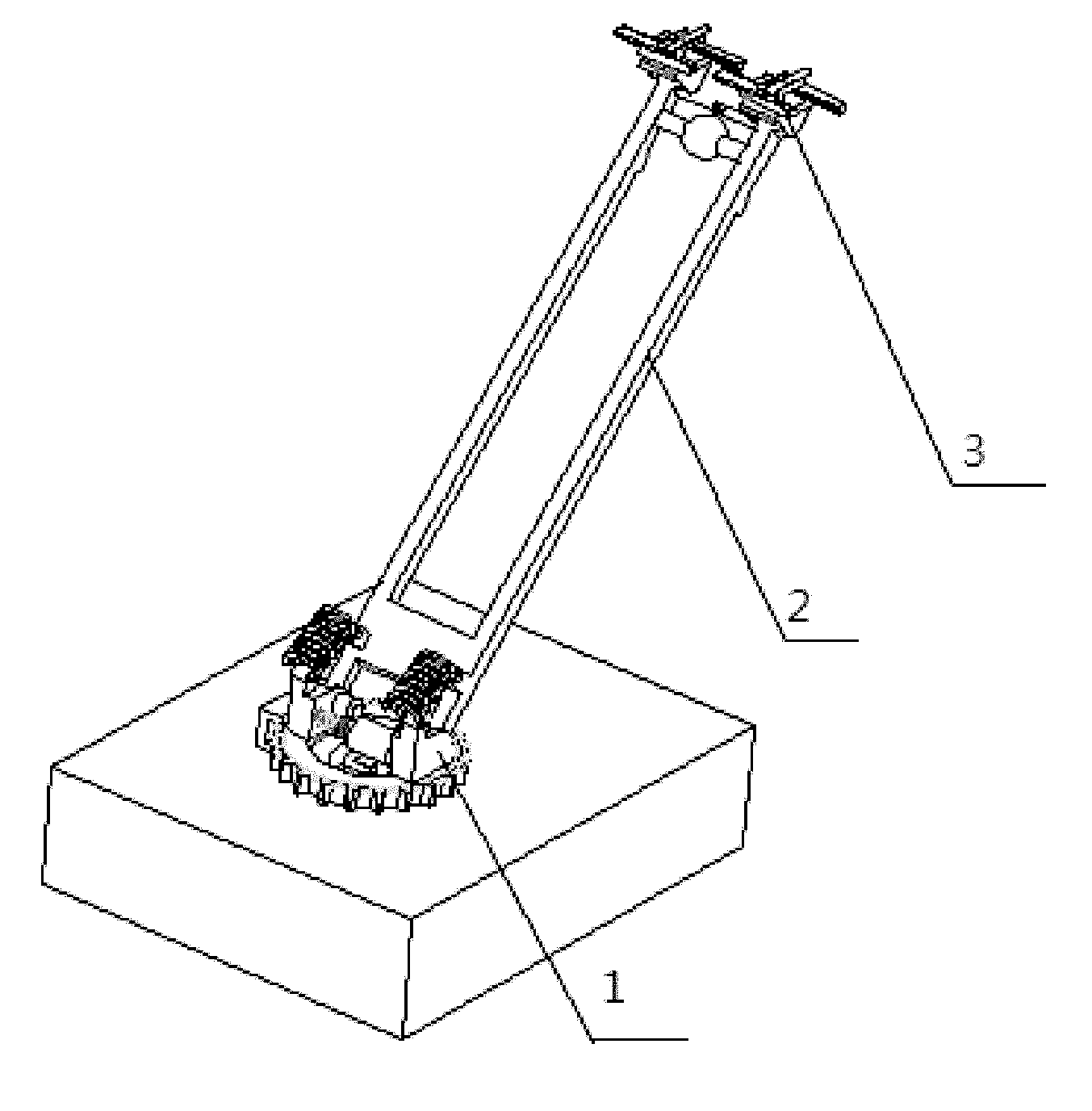

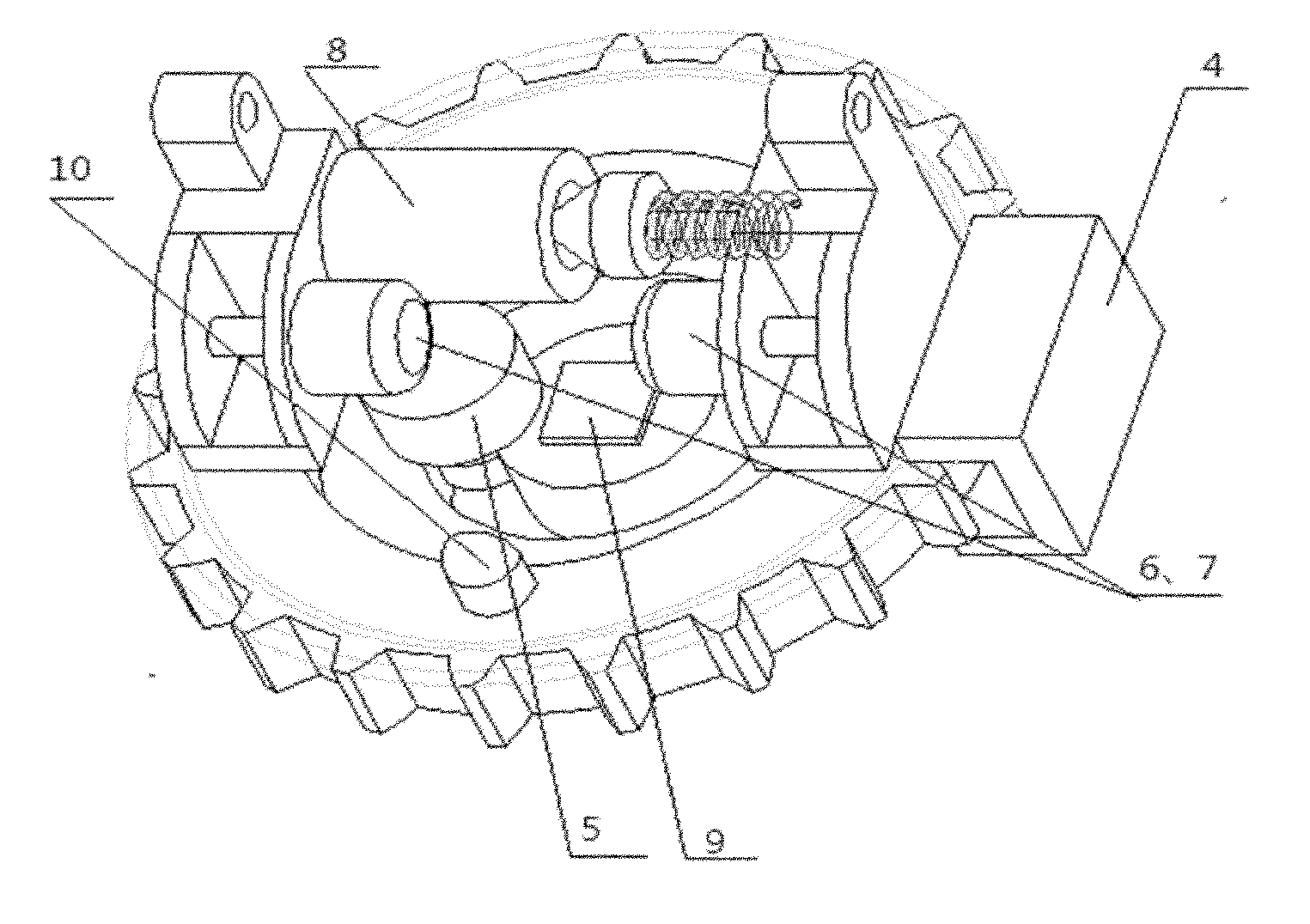

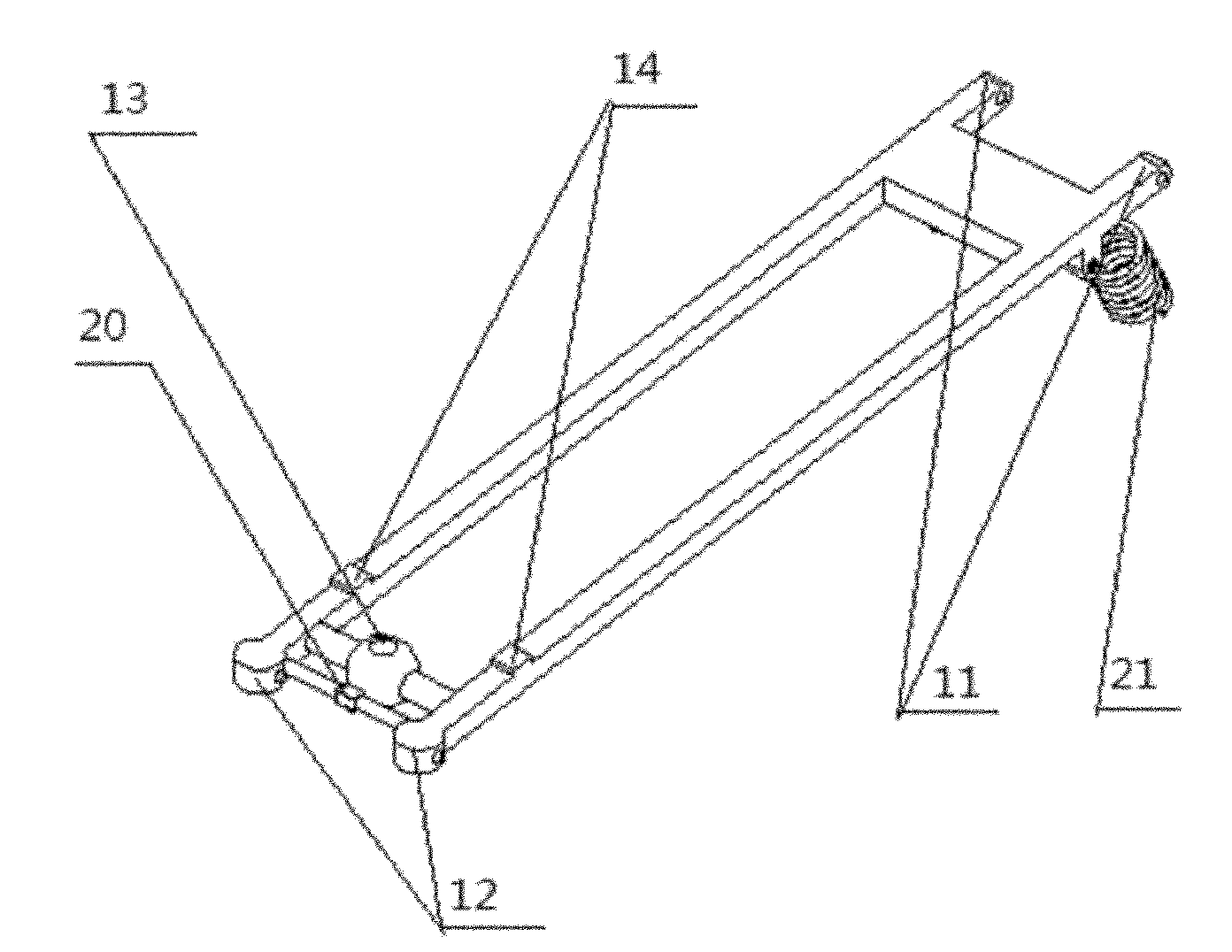

[0040] Specific implementation mode 1. Combination Figure 1 to Figure 4 To illustrate the implementation mode, the intelligent pantograph device for a trolley bus includes a pantograph assembly, a pantograph assembly and a clamp assembly 3, one end of the pantograph assembly is installed on the roof, and the other end of the pantograph assembly is connected to the pantograph assembly. One end of the pantograph assembly is hinged, and the other end of the bow frame assembly is hinged with the clamp assembly 3; the bow base assembly includes a circular bow base body 1, a pantograph rotating motor 5, a pantograph position sensor 4, and a first pantograph lifting motor 6 , the second pantograph lifting motor 7, the camera 10, the main circuit breaker 8 and the central controller 9; the first pantograph lifting motor 6 and the second pantograph lifting motor 7 are installed symmetrically on the circular bow base body 1 On the boss used to articulate the pantograph assembly, the pa...

specific Embodiment approach 2

[0048] Specific embodiment two, combine Figure 5 to Figure 8 Describe this embodiment, the application method of trolley bus intelligent pantograph, this method is realized by the following steps:

[0049] Step 1. After the trolley bus enters the electrified section, the driver uses the left and right adjustment buttons to adjust the position of the pantograph according to the image obtained by the camera 10, so that the contact line is located within the lens range of the infrared camera 20, and starts the bow raising procedure;

[0050] The specific process of the bow raising program is: disconnect the main circuit breaker 8, separate the movable line clamp 16, call the contact line tracking program to locate the position of the contact line, control the bow base rotation motor 5 to move the bow head of the pantograph directly below the contact line Nearby, this position can ensure that the contact line is embedded in the middle of the separated movable wire clip after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com