Copper-chromium-zirconium alloy contact wire and production technique thereof

A production process and contact wire technology, applied in the direction of metal/alloy conductors, conductive materials, conductive materials, etc., can solve the problems of difficulty in meeting the high strength and high conductivity requirements of catenary wires, and the inability to continuously produce rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

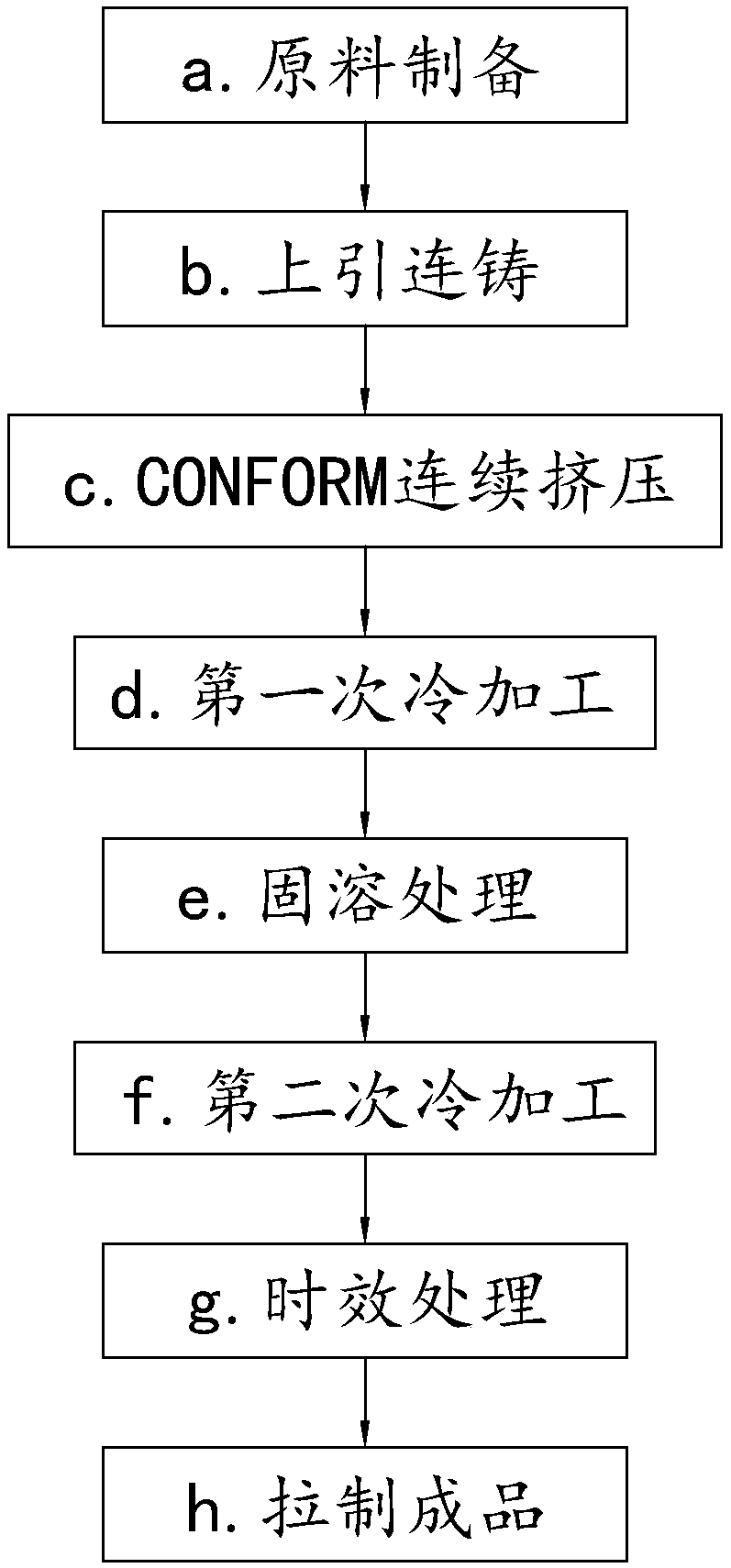

[0032] a. raw material preparation;

[0033] b. Upward continuous casting: using cathode copper plate, copper-chromium master alloy and copper-zirconium master alloy as raw materials for upward continuous casting, the temperature of copper liquid is controlled at 1200-1300°C, the single root speed is controlled at 100kg / h, and the cooling water of the crystallizer enters and exits The water temperature difference is 8-10°C, the diameter of the upper casting rod is 25mm, where ω(Cr)=0.72%, ω(Zr)=0.06%;

[0034] c. CONFORM continuous extrusion: tooling mold and preheating material preheating temperature 650 ℃, heat preservation 2h, extrusion gap controlled at 0.6mm, extrusion ratio controlled at 2.6, extrusion rod diameter 36mm, rod billet feed line speed controlled at 5m / min;

[0035] d. The first cold processing: use cold rolling equipment or drawing equipment to cold-roll the above-mentioned 36mm extruded rod to 28mm, the total cold processing amount> 40%, take up the w...

Embodiment 2

[0043] a. raw material preparation;

[0044] b. Upward continuous casting: use cathode copper plate, pure chromium, and pure zirconium as raw materials for upward continuous casting. The temperature of copper liquid is controlled at 1300-1400°C, and the single lead speed is controlled at 80kg / h. Ensure that Cr and Zr elements are evenly dissolved into the copper matrix. The temperature difference between the inlet and outlet of the crystallizer cooling water is 8-10°C. The diameter of the upward casting rod is 30mm. It is covered with graphite particles or graphite flakes. The thickness of the covering agent is greater than 15mm. Pass inert gas protection to avoid contact between copper water and air, where ω(Cr)=0.68%, ω(Zr)=0.07%;

[0045] c. CONFORM continuous extrusion: the preheating temperature of tooling mold and preheating material is 650℃, heat preservation for 2h, the extrusion gap is controlled at 0.6mm, the extrusion ratio is controlled at 2.6, the diameter of t...

Embodiment 3

[0054] a. raw material preparation;

[0055] b. Upward continuous casting: use cathode copper plate, pure chromium, and pure zirconium as raw materials for upward continuous casting. The temperature of copper liquid is controlled at 1300-1400°C, and the single root speed is controlled at 70kg / h. Ensure that Cr and Zr elements are evenly dissolved into the copper matrix. The temperature difference between the inlet and outlet of the crystallizer cooling water is 8-10°C. The diameter of the upward casting rod is 20mm. It is covered with graphite particles or graphite flakes. The thickness of the covering agent is greater than 15mm. Pass inert gas protection to avoid contact between copper water and air, where ω(Cr)=0.15%, ω(Zr)=0.01%;

[0056] c. CONFORM continuous extrusion: tooling mold and preheating material preheating temperature 500 ℃, heat preservation 2h, extrusion gap is controlled at 0.4mm, extrusion ratio is controlled at 1.8, extrusion rod diameter is 40mm, rod bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com