Multifunctional fiber strand making machine

A strand-making machine and fiber technology, applied in the field of multi-functional fiber strand-making machines, can solve the problems of complex structure, single function, unstable operation, etc., and achieve the effect of stable operation and simple operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

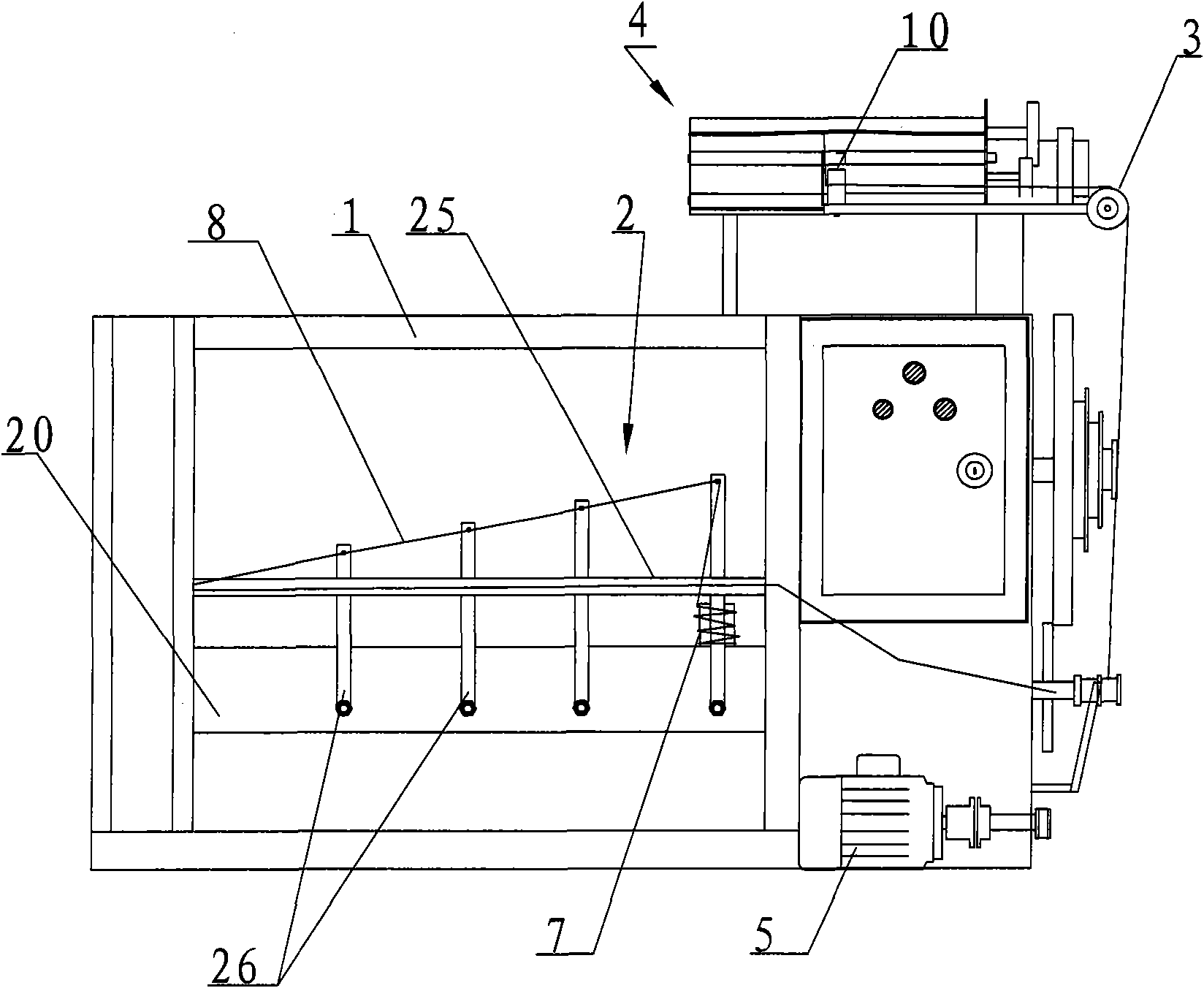

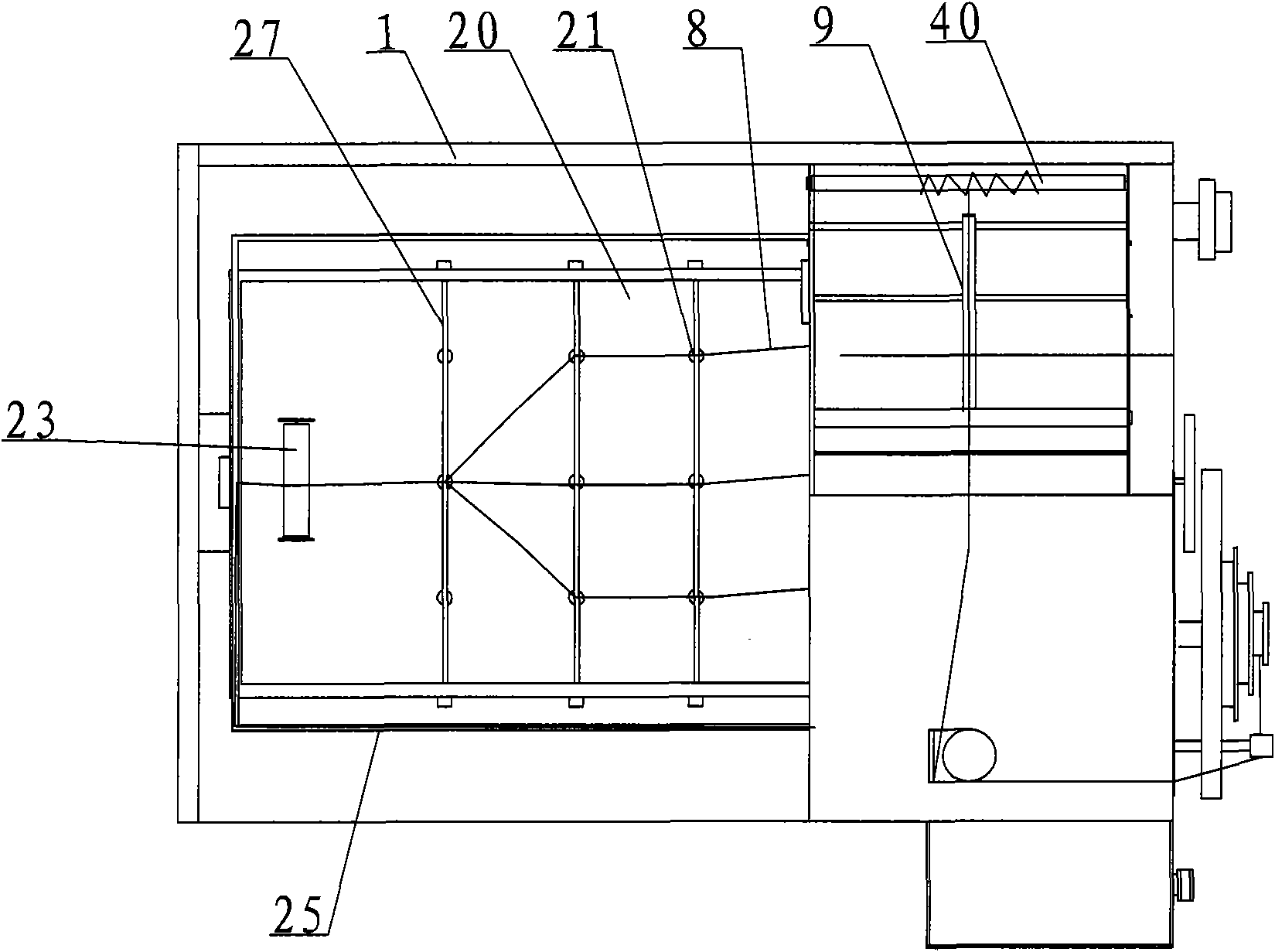

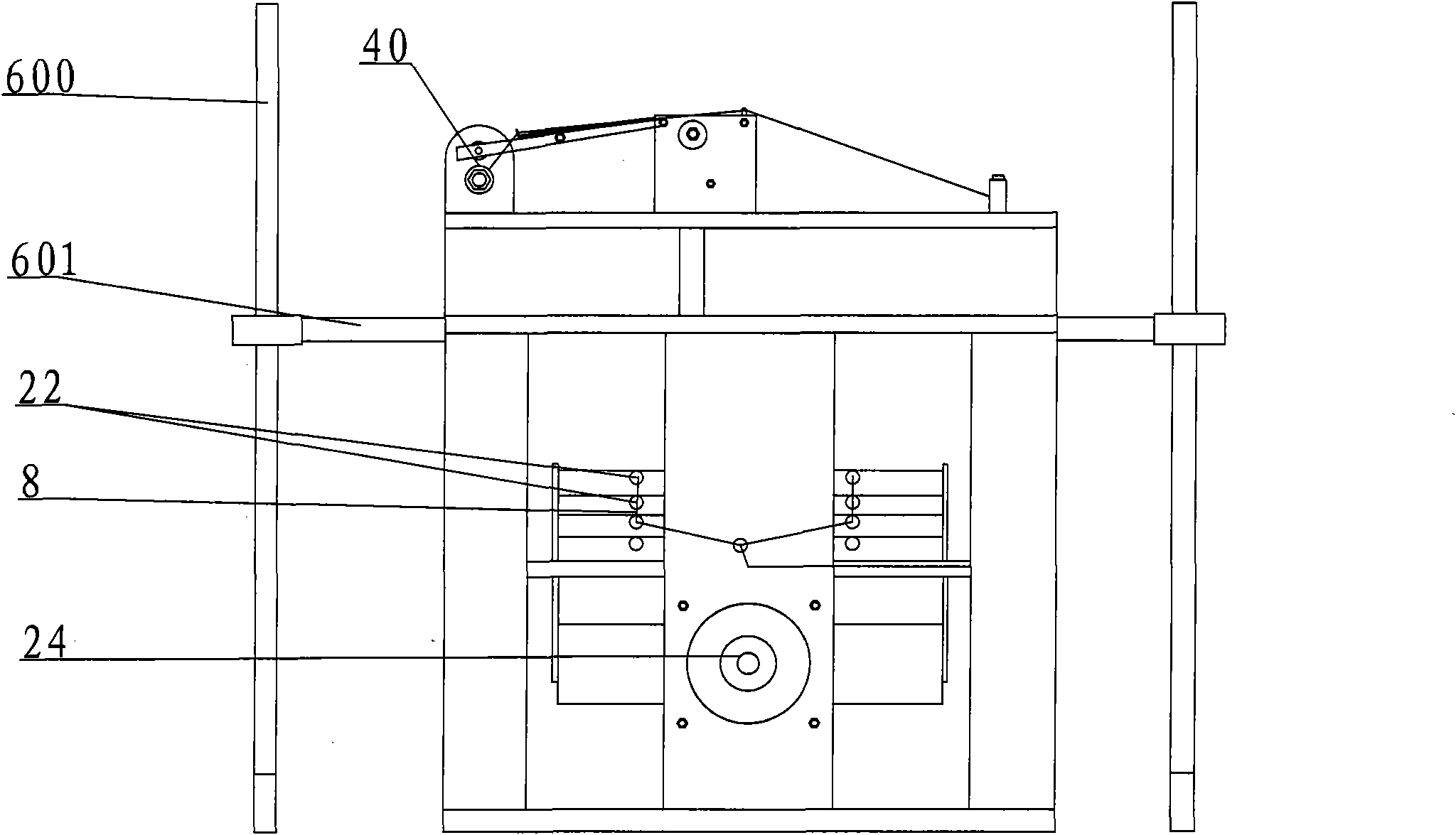

[0029] Such as Figure 1 to 5 As shown, the multifunctional fiber strand making machine according to the present embodiment mainly includes a frame 1, a twisting and plying device 2, a pulley 3, a reciprocating slider 9, a winding device 4, and a motor 5 arranged on the frame 1. : The winding device 4 includes a take-up shaft 40 rotatably arranged around its own axis, a gear (not shown) for driving the take-up shaft 40 to rotate, and a take-up roller 41 installed on the take-up shaft 40. Each part is explained in detail below.

[0030] In this example, the twisting and plying device 2 includes a rectangular carrier plate 20 arranged on the frame 1, a plurality of fixed posts 21 arranged on the carrier plate 20 for placing the fiber roll 7, and the carrier plate 20 is arranged along the carrier plate 20. The four guide coil supports distributed in the length direction of the disk 20, the three guide coils 22 arranged on each guide coil support, the crimping wheel 23 arranged on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com