Production method of high-power precision alloy SMD (surface mount device) resistor

A technology of precision alloys and chip resistors, which is applied in the direction of resistors, resistor manufacturing, and resistors at the lead-out end. It can solve problems such as unstable circuit performance, high cost, and overall heat accumulation, and achieve material saving and reliability. Excellent thermal stability and low thermoelectric potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

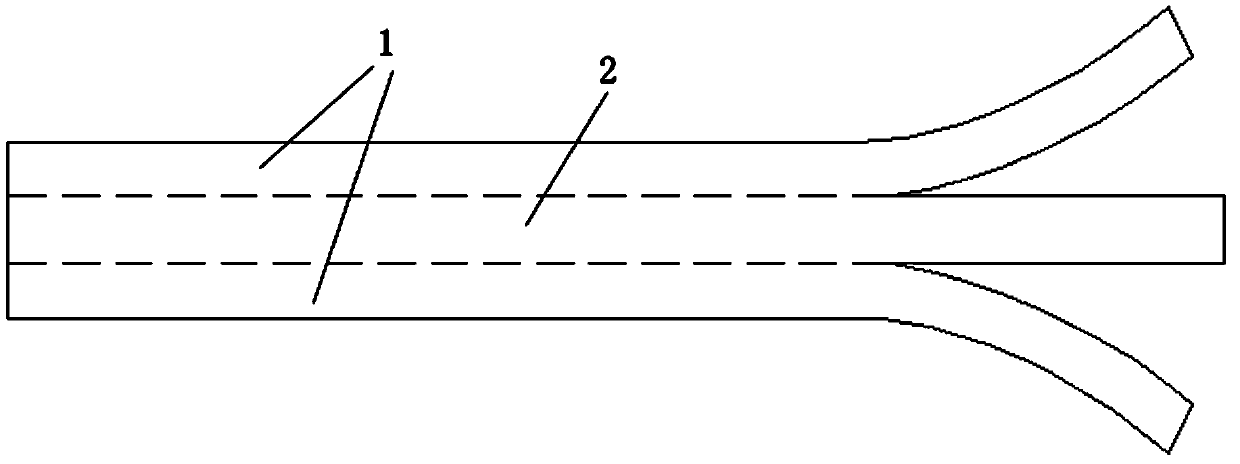

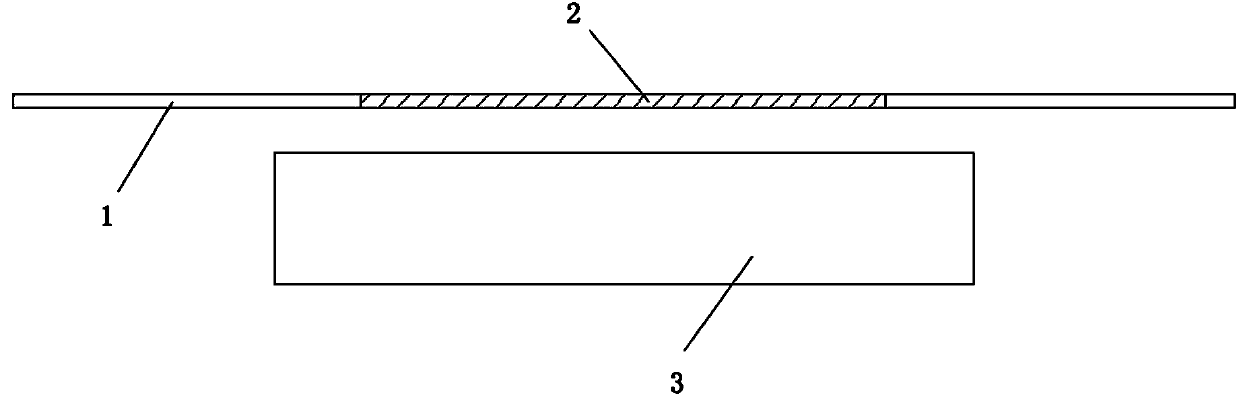

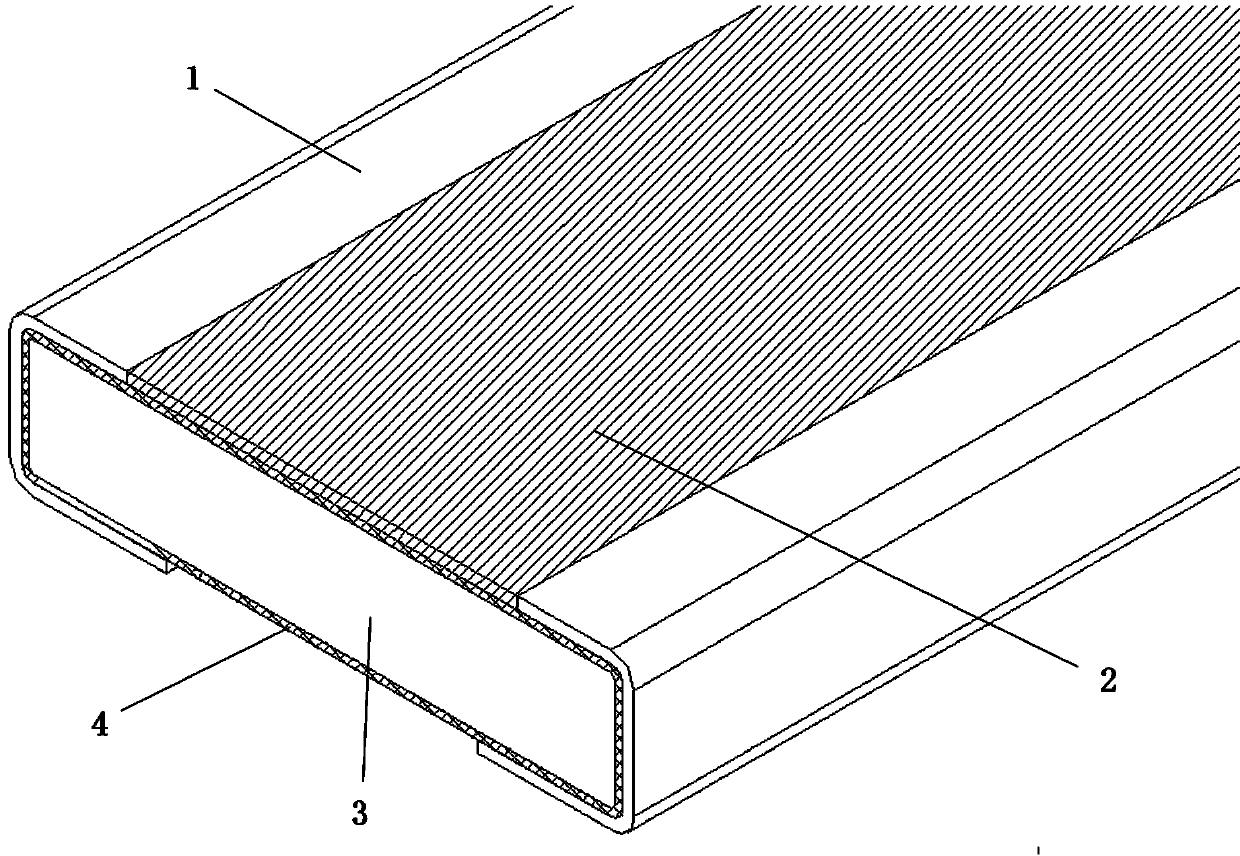

[0029] Such as Figure 1~3 Shown, the manufacture method of the high-power precision alloy chip resistor of the present invention, it comprises the steps:

[0030] a. Utilize the welding process or the pressing process to combine two oxygen-free copper strips 1 with the two sides of the resistance alloy strip 2 respectively to form an integral strip-shaped resistor strip, the oxygen-free copper strip And the section of the resistance alloy strip is rectangular;

[0031] b. Wrap the resistor strip on a strip-shaped substrate 3 with high thermal conductivity, the surface of the substrate 3 is insulated;

[0032] c. Etch the basic resistance structure on the inclusion wrapped with the substrate 3 by chemical etching or laser engraving or grinding, such as Figure 4-7 shown;

[0033] d. Refer to Figure 8 , on the basic resistance structure, the resistance value is precisely adjusted 5, and the adjustment can be made by laser engraving or grinding or chemical etching;

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com