Production technology of big-length oxygen-free copper stripe

A production process, oxygen-free copper technology, applied in the direction of manufacturing tools, metal processing equipment, metal extrusion control equipment, etc., can solve the problems of long process flow, large environmental pollution, short length, etc., to achieve complex process, processing High performance, dimensionally accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

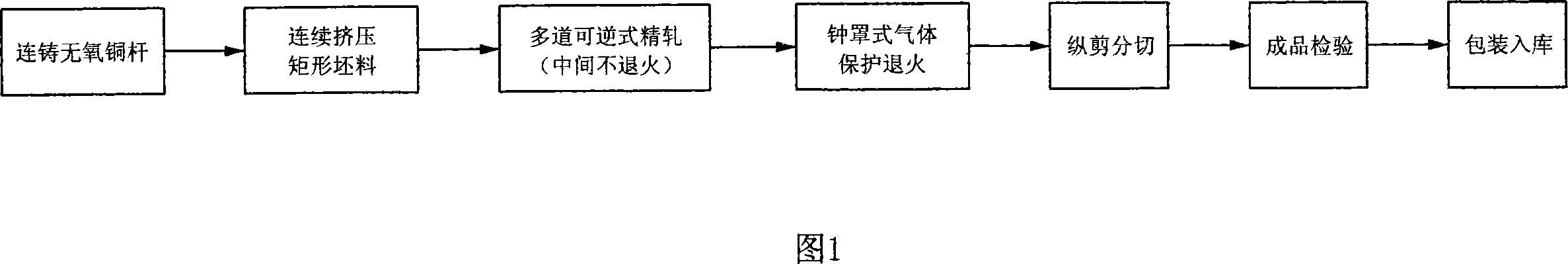

[0025] As shown in Figure 1, the technological scheme adopted by the present invention is as follows: continuous casting of oxygen-free copper rods—continuous extrusion of rectangular billets—multi-pass reversible finish rolling (no annealing in the middle)—bell-type gas shielded annealing— Slitting and slitting——finished product inspection——packaging and warehousing

[0026] 1. Continuous casting oxygen-free copper rod

[0027] High-quality No. 1 electrolytic copper is preferred as the raw material. After being melted in a power frequency electric furnace, steel carbon and wood phosphorus sheets are used to cover the reducing agent, and the oxygen-free copper rod is drawn up by the clutch-type vacuum of the traction unit, and then the oxygen-free copper rod enters the take-up device.

[0028] Main process parameters: copper content ≥ 99.95%;

[0029] Copper melting temperature 1150℃±10℃

[0030] Oxygen content of copper rod ≤10PPM

[0031] Leading rod speed 600-750mm / sec ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com