Stainless steel / alumina ceramic low stress hermetic seal solder

An alumina ceramic and stainless steel technology, applied in welding/cutting media/materials, welding equipment, welding media, etc., can solve the problems of low assembly efficiency, high production cost, and many operating procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

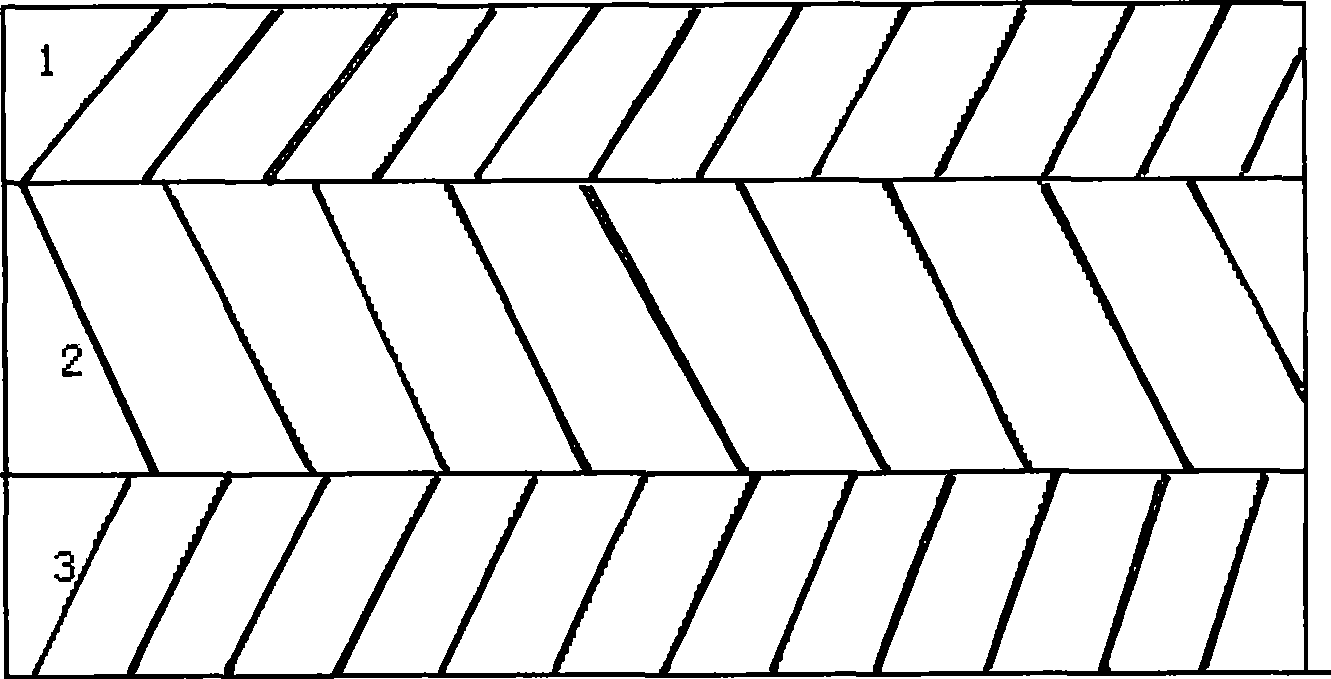

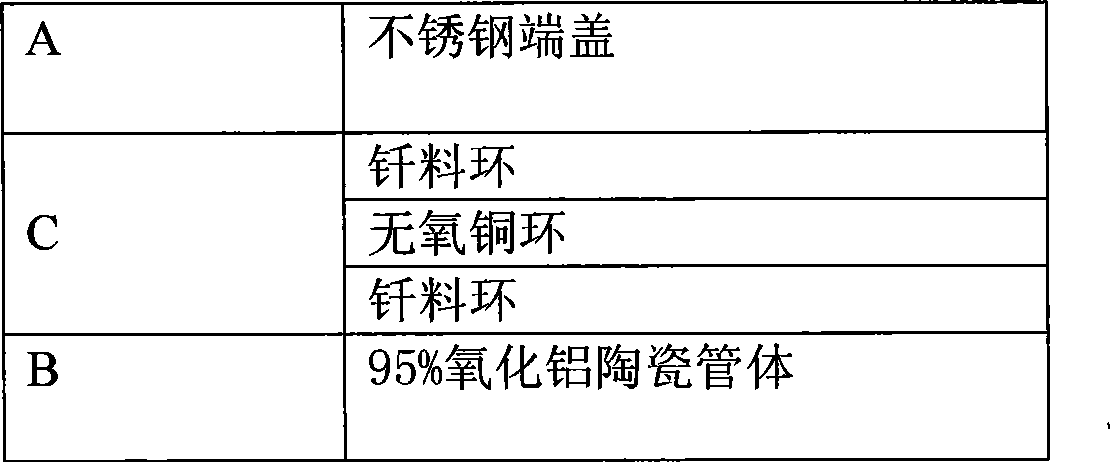

[0025] 1), one such as figure 1 The composition and composition of the silver alloy composite brazing material strip in the three-layer structure shown are:

[0026] (1) Silver solder composition (mass fraction): Ag: 71.0-72.0%; Cu: 27-29%; Ni: 0.5-1.0%;

[0027] Melting temperature of solder: 780-800°C; sealing temperature of composite solder: 820-830°C.

[0028] (2) Core layer: oxygen-free copper;

[0029] (3) Thickness of solder layer: 0.10mm;

[0030] (4) The composite ratio of the thickness of the solder layer and the thickness of the oxygen-free copper core layer: 1:2:1; the total thickness of the composite solder strip is 0.40mm;

[0031] 2) According to the size requirements of the sealing part, the above-mentioned silver composite solder strip is cold stamped into a welding ring, and placed on the 304 stainless steel end cap to be sealed and the 95% alumina ceramic tube that has been metallized and nickel-plated Between them, fix them with clamps of corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com