Metal extruding, casting and forging forming method and products of method

A metal extrusion, casting and forging technology, applied in metal processing equipment, mechanical equipment, transportation and packaging, etc., can solve the problem of small plastic deformation, and achieve the effect of good workpiece performance and low pouring temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with a preferred embodiment and accompanying drawings.

[0029] This embodiment provides a metal extrusion casting and forging forming method and its products, which is an aluminum alloy wheel with a designation of ZL101A (American designation A356.2, Japanese designation AC4CH), which includes the following steps:

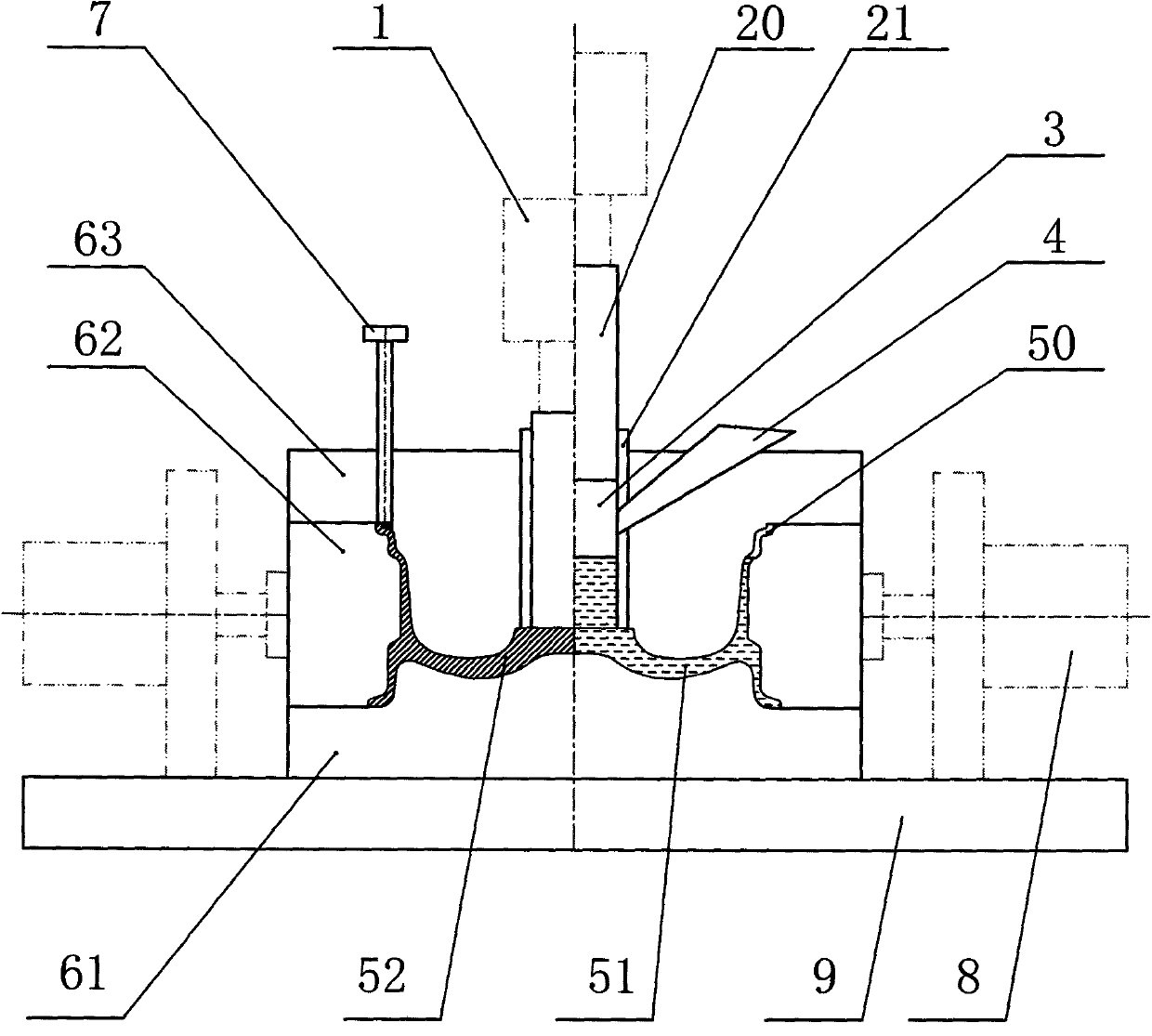

[0030] Step 1, equipment, mold, aluminum liquid, etc. are prepared; the equipment can be special extrusion casting and forging equipment or a refitted liquid die forging extrusion machine, die-casting machine, etc.; the mold includes a lower mold (61), a side mold (62), Upper mold (63), plunger (20), plunger sleeve (21) etc., also can not have side mold; Allow one mold to be many pieces; Mold is installed on the base plate (9), needs to clean, spray paint, preheat to 150-300℃, the mold cooling device can be used in continuous production; the pouring temperature of molten aluminum after ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com