Method for manufacturing dissimilar aluminum alloy composite automobile hub

A technology of dissimilar aluminum alloy and manufacturing method, which is applied to manufacturing tools, metal processing equipment, non-electric welding equipment, etc., can solve the problems of heat concentration at the axle, slow solidification speed, and coarse grains, so as to improve overall performance and simplify production. Process, the effect of simplifying the welding jig

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

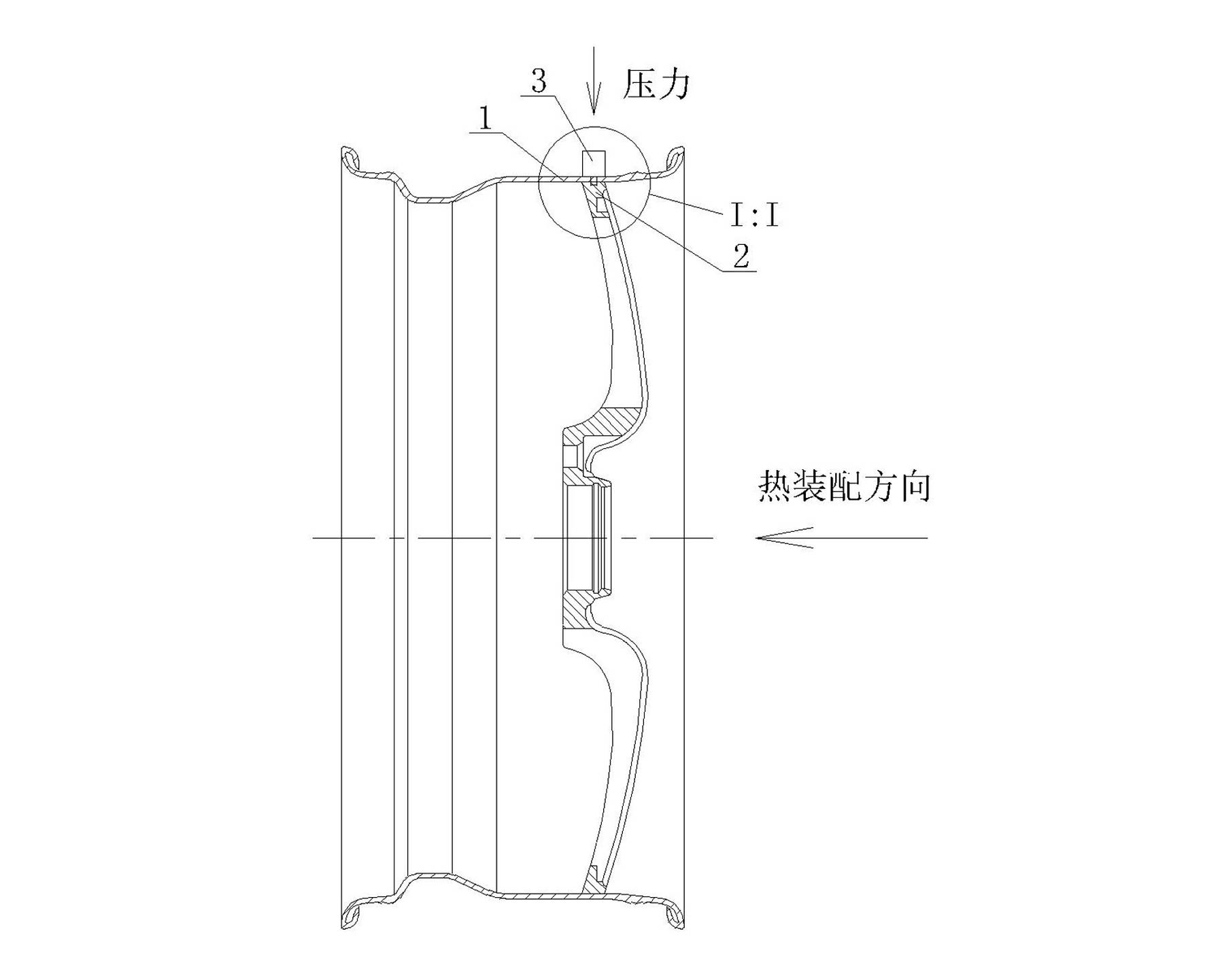

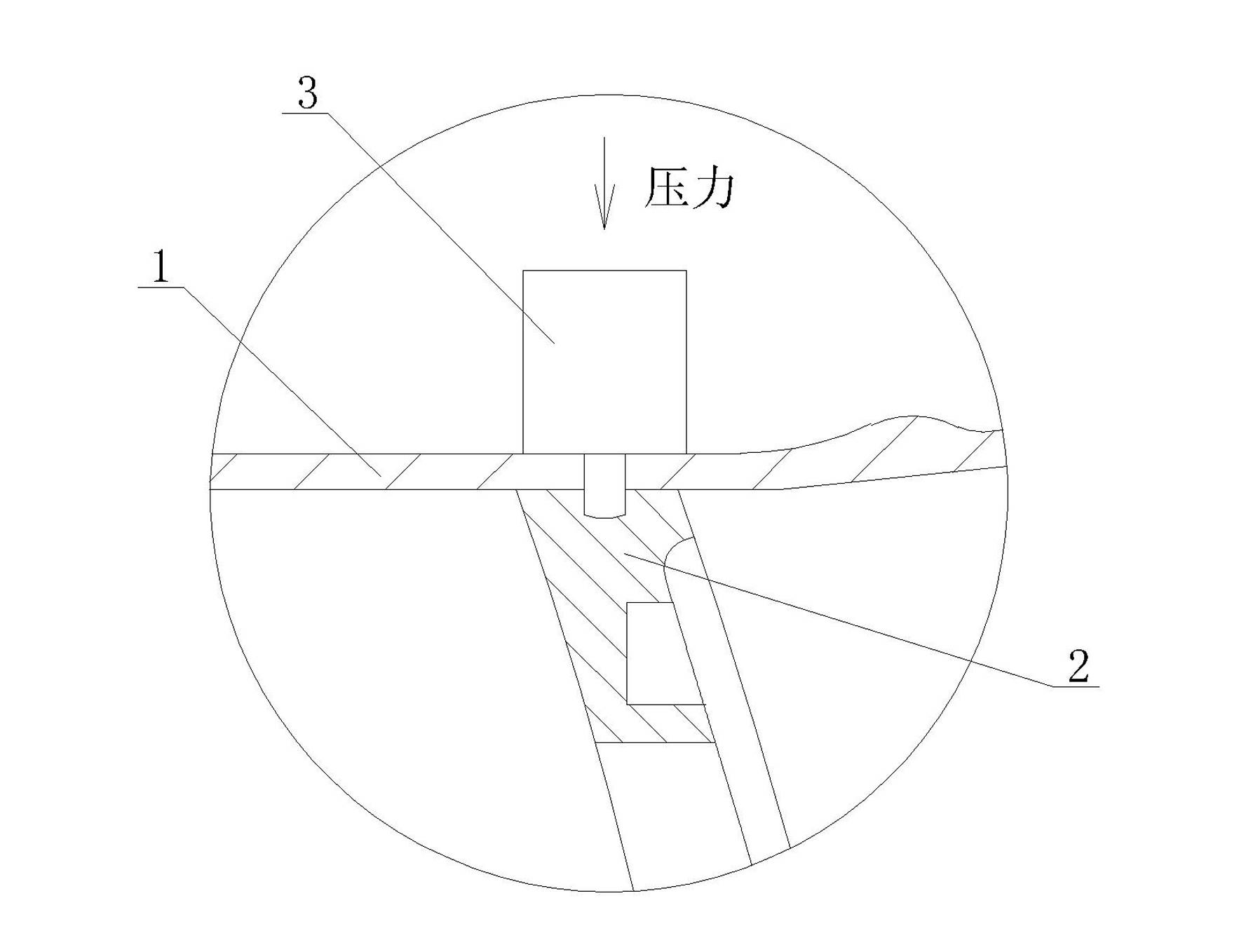

[0022] The manufacturing method of heterogeneous aluminum alloy composite automobile wheel hub of the present invention, comprises the following steps:

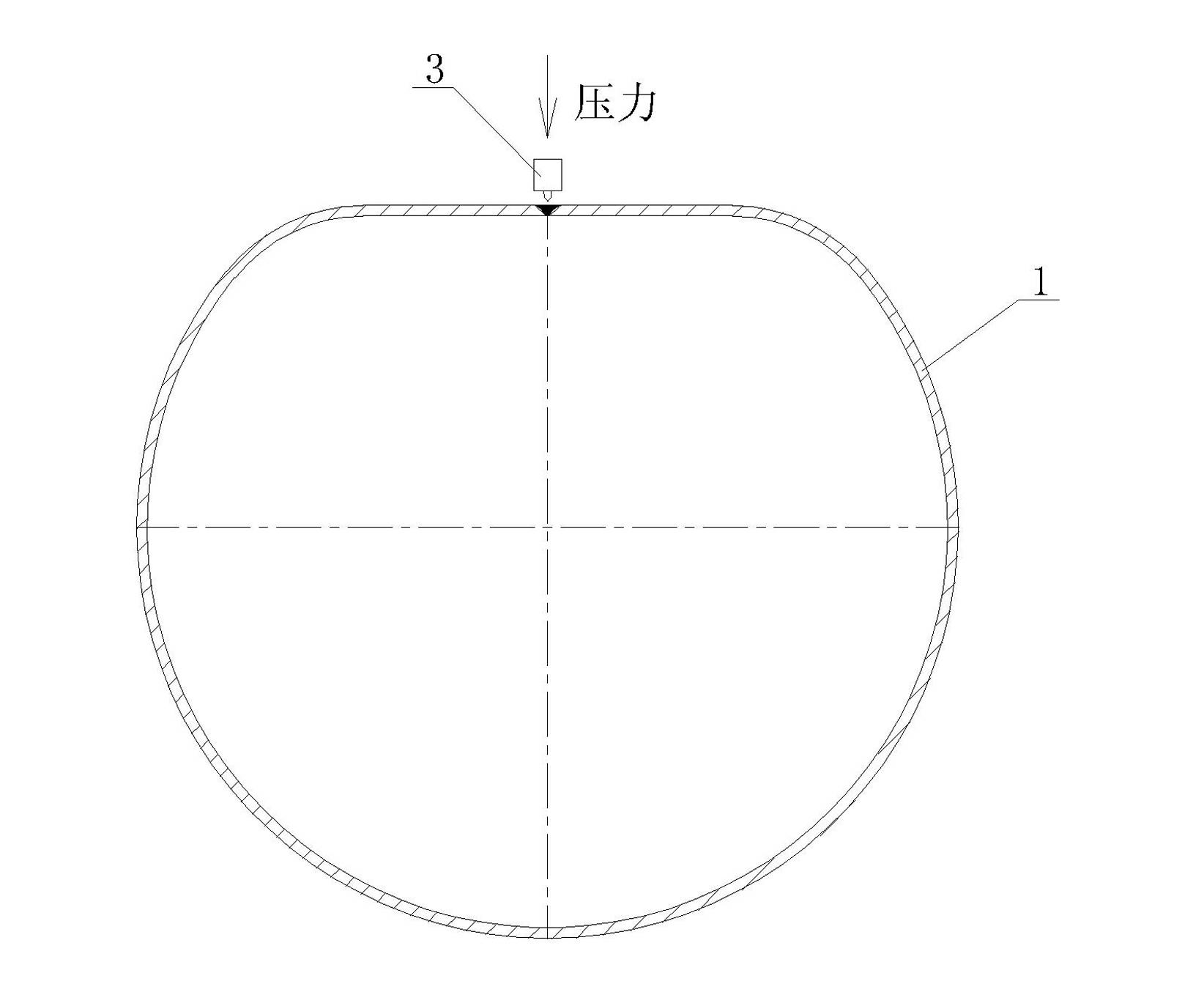

[0023] First, manufacture the wheel rim 1, the method and steps are as follows: First, use the annealed (O state) 6061 deformed aluminum alloy plate to roll into a "D" shaped cylinder, such as image 3 As shown; Then, put the "D" shaped cylinder on the special fixture and perform flat longitudinal seam welding on it by friction stir welding. The welding process is that the rotation speed of the stirring head is 1200r / min, and the walking speed of the workpiece is 300~ 400mm / min; Next, roll the "D"-shaped cylinder into a circular cylinder; then, put the circular cylinder on a horizontal spinning machine and spin it into rim 1; finally, perform T6 heat treatment on rim 1 , the heat treatment specification is: 535°C for 4 hours + water quenching, water quenching requires water temperature not lower than 80°C, and water should be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com