Shortened method for producing oxygen-free copper belt

A production method and technology of oxygen-free copper, which is applied in the field of copper strip casting and processing, can solve the problems of high oxygen content, low efficiency, not as accurate as size and smoothness, etc., and achieves low oxygen content, short process flow and uniform size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

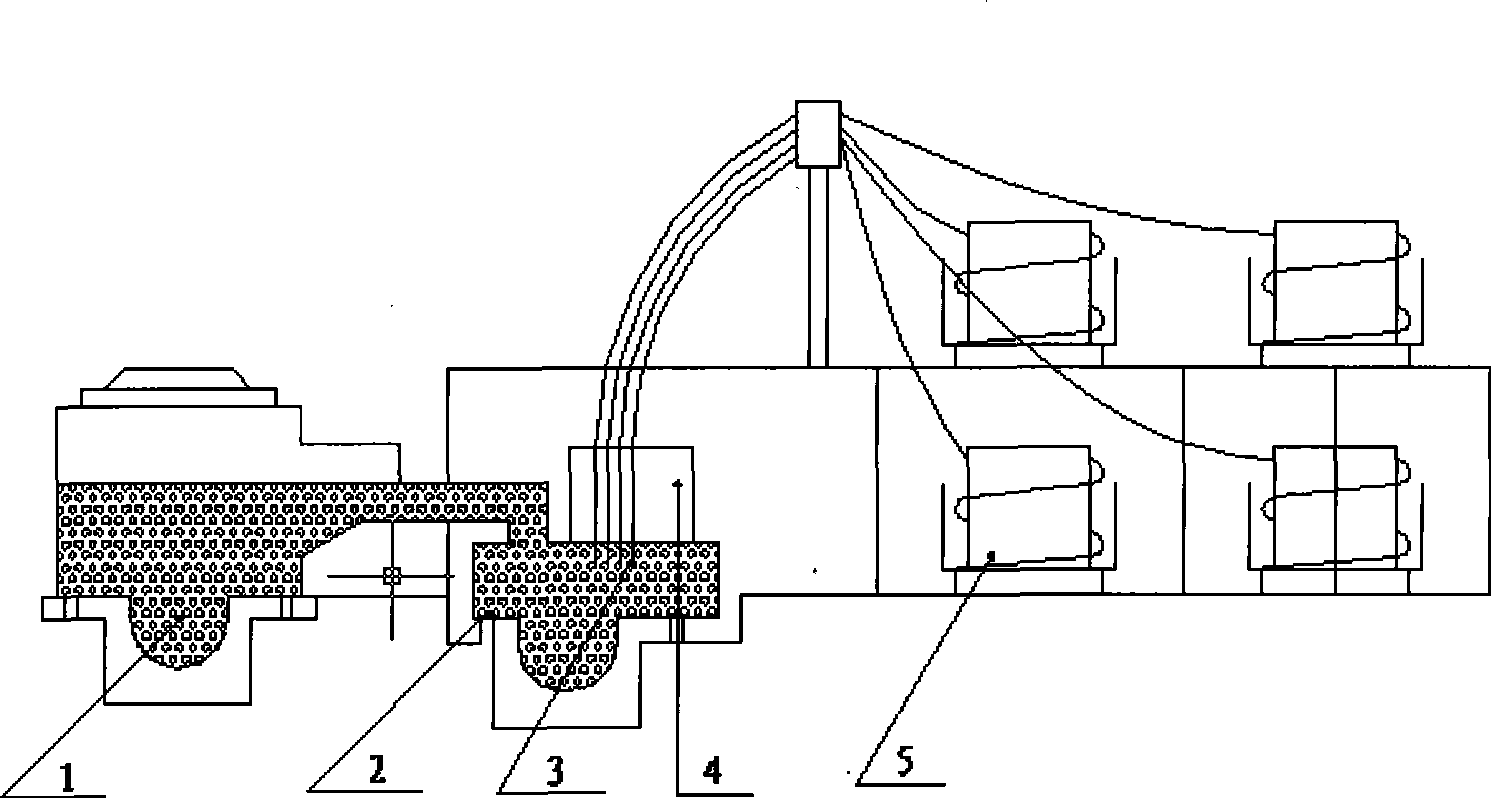

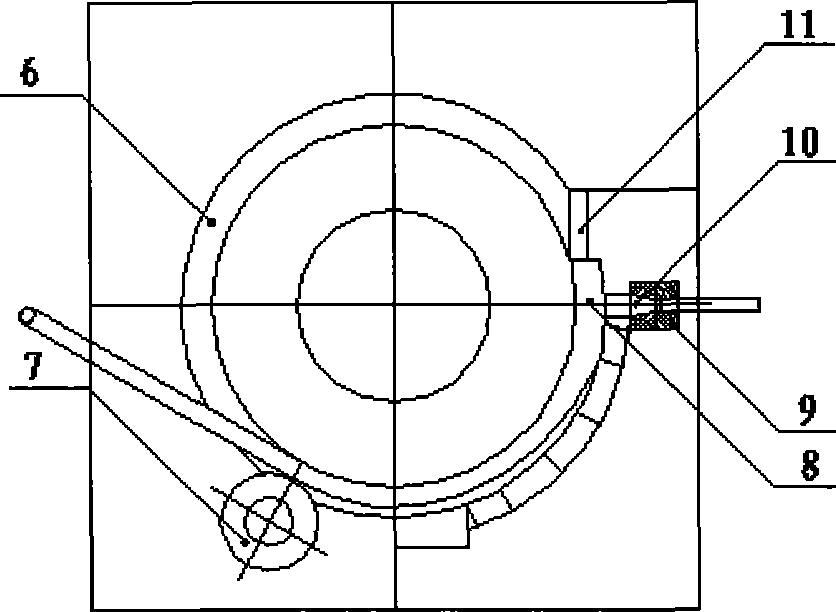

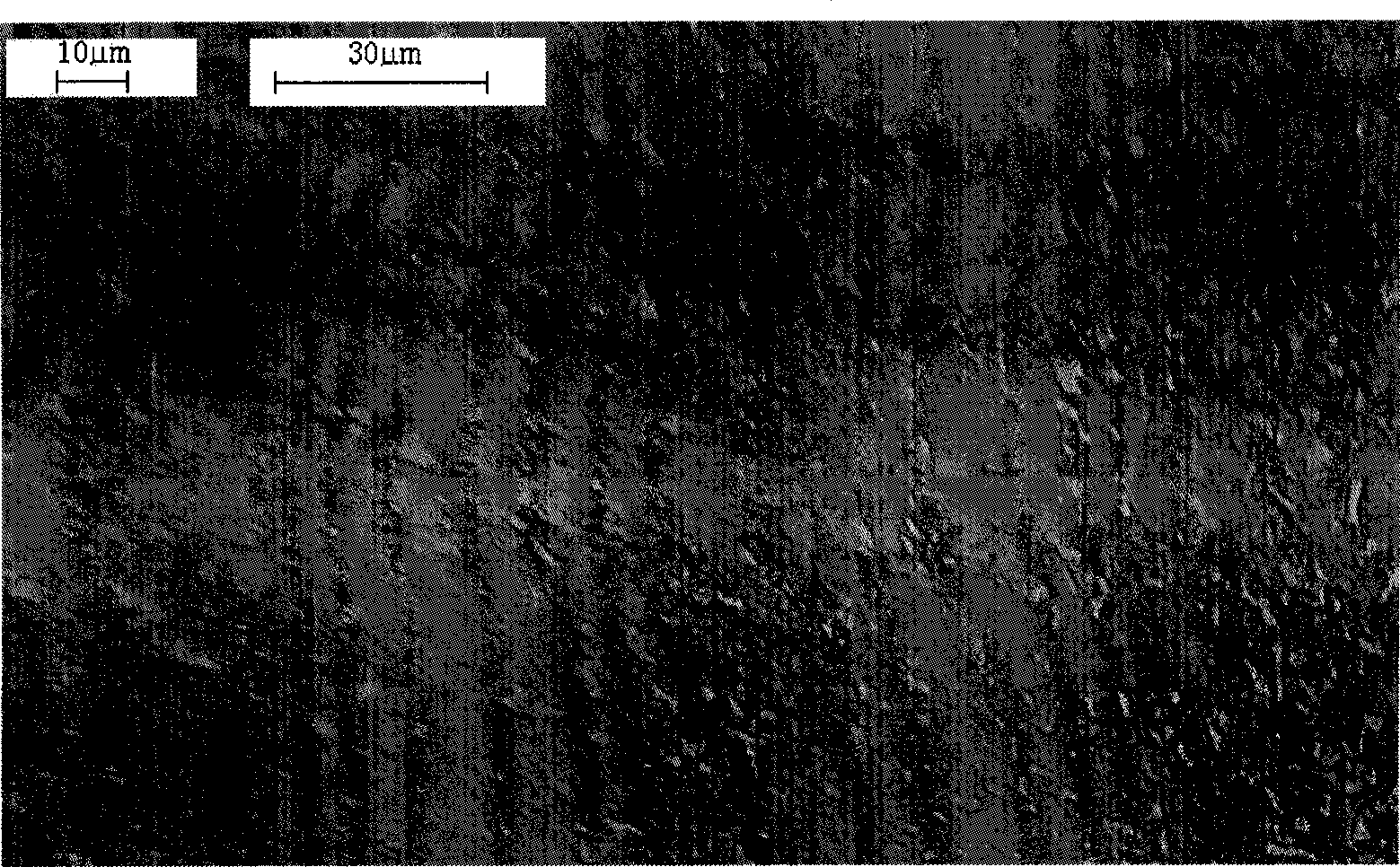

[0033] A short-process oxygen-free copper strip production method, the specific steps are: the electrolytic copper plate is cleaned by a steel brush and then preheated and dried, then added to the melting chamber 1, melted at 1160 ° C, kept for about 15 minutes, and flowed through the launder to Insulation chamber 2 is kept at 1140°C, and the voltage is adjusted through a voltage regulator so that the temperature of the copper liquid in the insulation chamber 2 reaches the casting temperature, and the crystallizer 3 with circulating cooling water in the graphite mold is inserted into the copper liquid, and the cooling cycle The water inlet temperature is 25°C, the water pressure is 0.2Mpa, and it is drawn out with a dummy rod, and the solidified copper rod is continuously pulled out through the traction device 4, and is looped by the take-up device 5. During the production process, the melting chamber is evenly fed, and the heat preservation chamber is continuously drawn up for...

Embodiment 2

[0037] A short-process oxygen-free copper strip production method, the specific steps are: the electrolytic copper plate is cleaned by a steel brush, preheated and dried, and then added to the melting chamber 1. After melting at 1180 ° C, it is kept for about 15 minutes, and flows through the launder to Insulation cavity 2 is kept at 1160°C, and the voltage is adjusted through a voltage regulator so that the temperature of the copper liquid in the insulation cavity 2 reaches the casting temperature, and then the crystallizer 3 with circulating cooling water in the graphite mold is inserted into the copper liquid, and the cooling cycle The water inlet temperature is 35°C, the water pressure is 0.4Mpa, and it is drawn out with a dummy rod, and the solidified copper rod is continuously pulled out through the traction device 4, and formed into a loop by the take-up device 5. During the production process, the melting chamber is evenly fed, and the heat preservation chamber is conti...

Embodiment 3

[0041] A short-process oxygen-free copper strip production method, the specific steps are: the electrolytic copper plate is cleaned by a steel brush, preheated and dried, added to the melting chamber 1, melted at 1170 ° C, kept for about 15 minutes, and flowed through the launder to Insulation cavity 2 is kept at 1150°C, and the voltage is adjusted through a voltage regulator so that the temperature of the copper liquid in the insulation cavity 2 reaches the casting temperature, and then the crystallizer 3 with circulating cooling water in the graphite mold is inserted into the copper liquid, and the cooling cycle The water inlet temperature is 30°C, the water pressure is 0.3Mpa, and it is drawn out with a dummy rod, and the solidified copper rod is continuously pulled out through the traction device 4, and looped by the take-up device 5. During the production process, the melting chamber is evenly fed, and the heat preservation chamber is continuously drawn up for casting. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com