High-thermal-conductivity silicon nitride ceramic copper-clad plate and manufacturing method thereof

A technology of silicon nitride ceramics with high thermal conductivity, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems affecting the reliability of power modules, low bending strength and fracture toughness, and easy cracking and other problems, to achieve the effect of strong temperature shock resistance, improved strength and impact resistance, and less voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

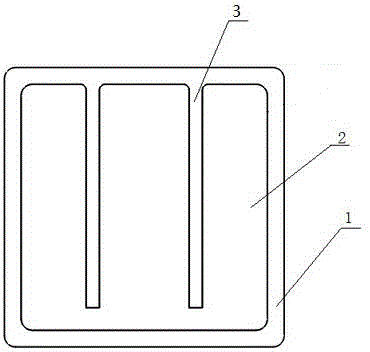

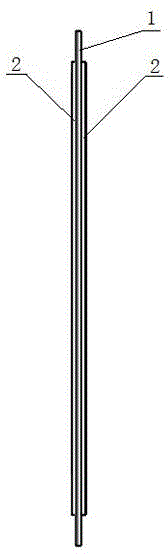

Image

Examples

preparation example Construction

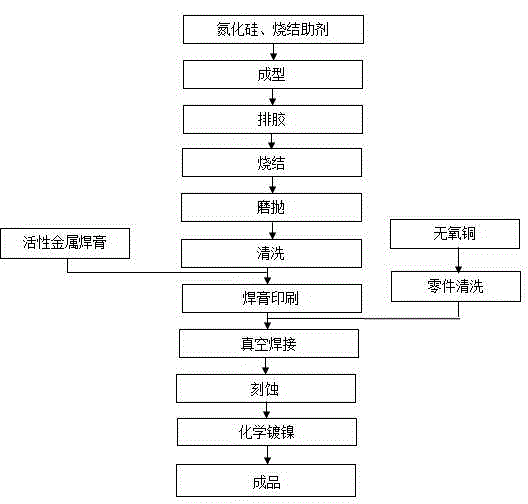

[0022] Such as image 3 As shown, the method for preparing a high thermal conductivity silicon nitride ceramic copper clad laminate of the present invention includes the following steps:

[0023] (1) Mixing ceramic powder and sintering aids into porcelain powder, the weight content of the ceramic powder is 90%-96%, and the sintering aids are yttrium oxide, aluminum oxide, magnesium oxide, and calcium oxide. One or more of the components, the weight content of which is 4%-10%, the thin-plate silicon nitride ceramic body is prepared by dry pressing, casting or gel injection molding;

[0024] (2) The thin-plate silicon nitride ceramic body is sintered under atmospheric pressure to prepare high thermal conductivity silicon nitride ceramic, and the ceramic surface is ground and polished to obtain a high thermal conductivity silicon nitride ceramic substrate;

[0025] (3) Stir and mix the metal Ag, Cu, Ti or Ag, Cu, Zr powders and then add an organic binder and stir to prepare Ti-Ag-Cu or...

Embodiment 1

[0030] Example 1: The above steps are the same, the weight content of the ceramic powder component is 90%. The sintering aid component is one or more of yttrium oxide, aluminum oxide, magnesium oxide, and calcium oxide, and its component weight content is 10% .

Embodiment 2

[0031] Example 2: The above steps are the same, the weight content of ceramic powder components is 96%. The sintering aid component is one or more of yttrium oxide, aluminum oxide, magnesium oxide, and calcium oxide, and its component weight content is 4% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com