Top gun applied to steel production

A top gun and steel technology, applied in the field of steel production, can solve the problems of large amount of oxygen blowing, large amount of wear on the surface of the hole, wear and water leakage of the pipe wall, etc., and achieve the effects of reducing corrosion of refractory materials, improving processing accuracy and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below with reference to the accompanying drawings, through the description of the implementation examples, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between each part, the role and working principle of each part, etc., will be further described. Detailed instructions:

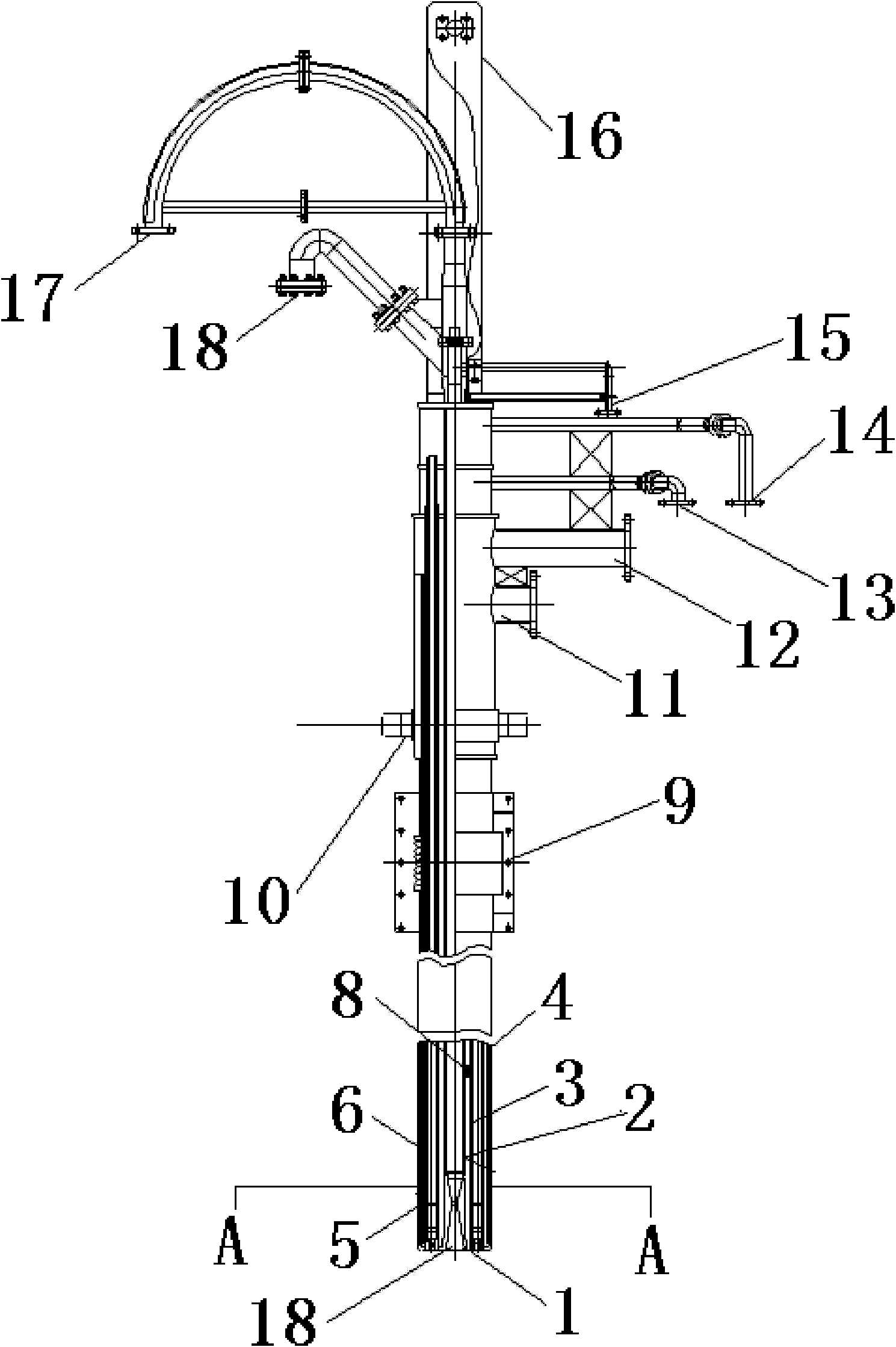

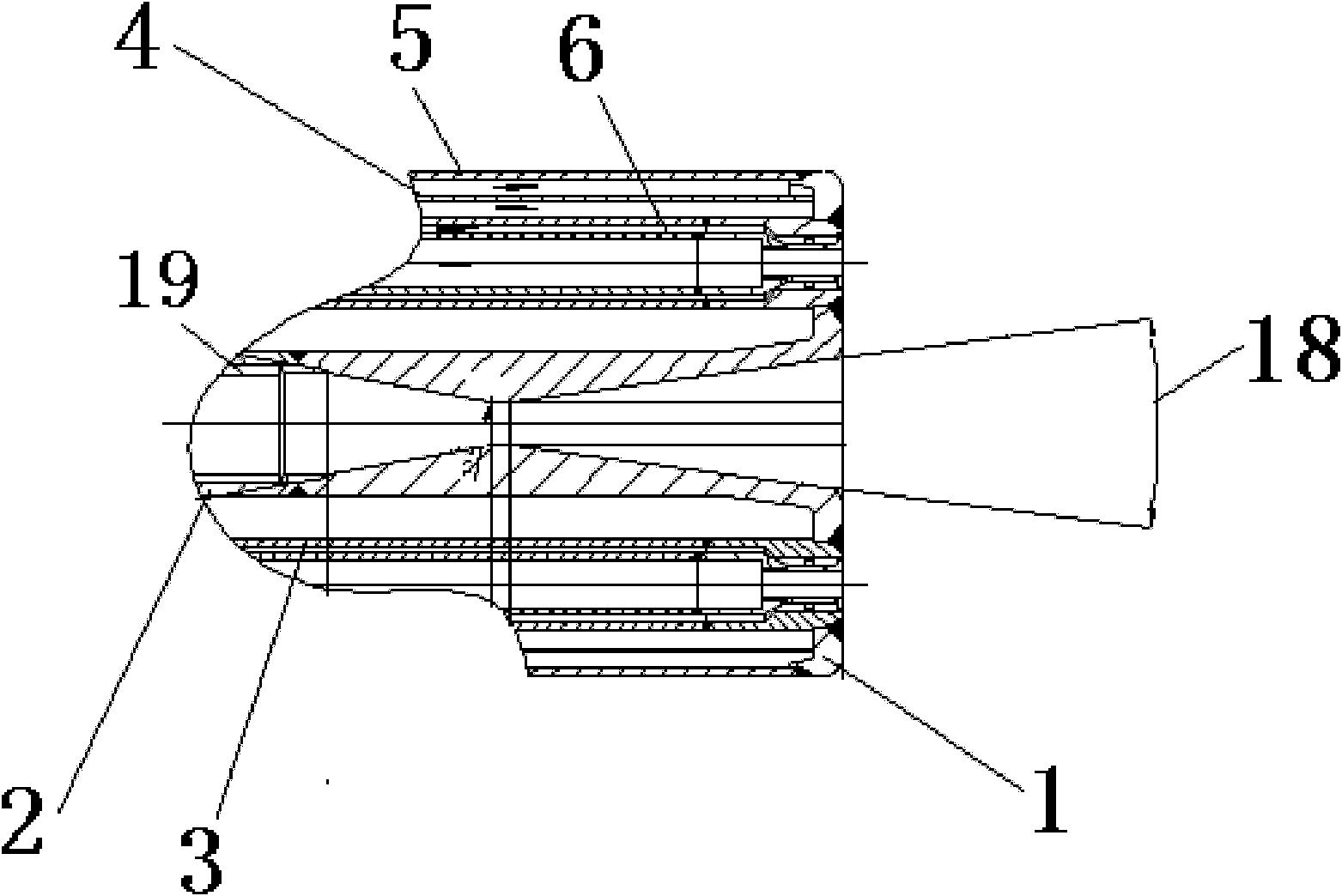

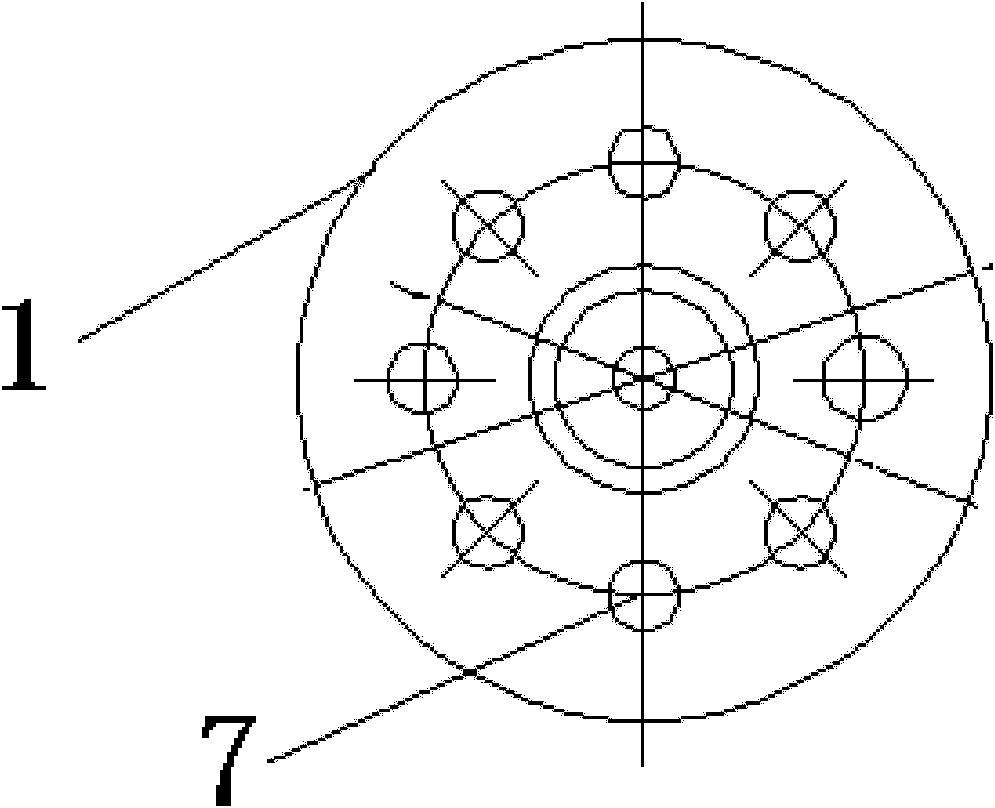

[0022] as attached Figure 1-3 As shown, the present invention is a top gun applied to steel production, including a Laval gun head 1, a Laval gun head center pipe 2, a gas pipe 3, a water riser 4, an outer pipe 5, an oxygen pipe 6, and a flame detector Mounting hole 7, isolation device 8, gun body telescopic adjustment device 9, suspension device 110, cooling water outlet pipe 11, cooling water inlet pipe 12, combustion oxygen inlet pipe 13, gas inlet pipe 14, nitrogen gas inlet pipe 15, suspension Hanging device II 16, central oxygen inlet pipe 17, the Laval gun head 1 of the top gun used in steel production is set to T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com