Butt welding machine for constructional engineering

A technology of construction engineering and butt welding machines, which is applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of wasting time and low work efficiency, and achieve the goal of improving work efficiency, reducing time occupied, and ensuring positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

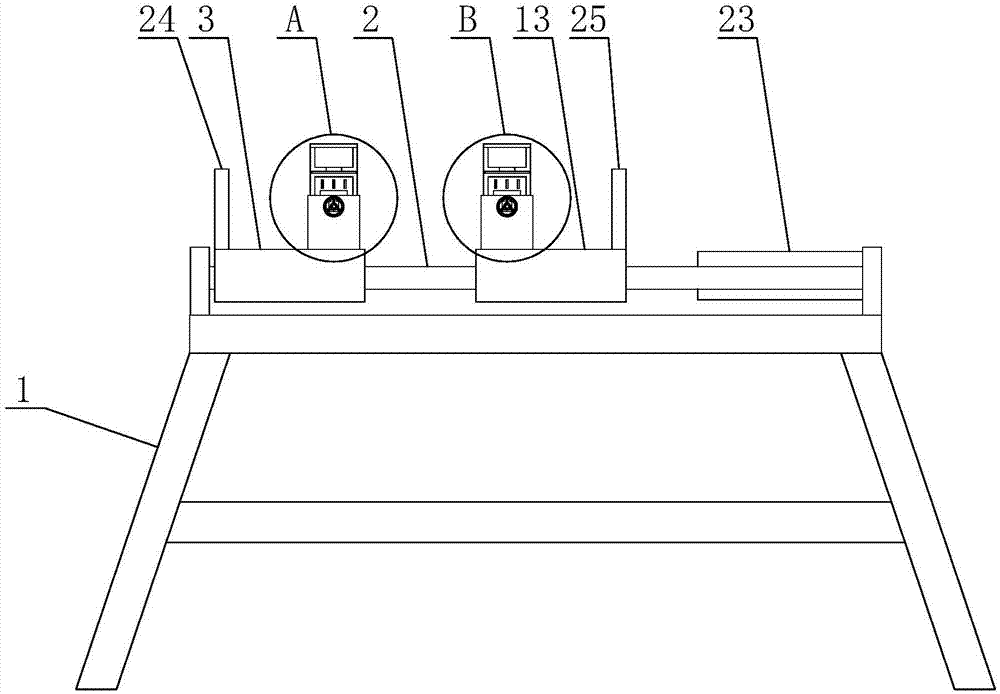

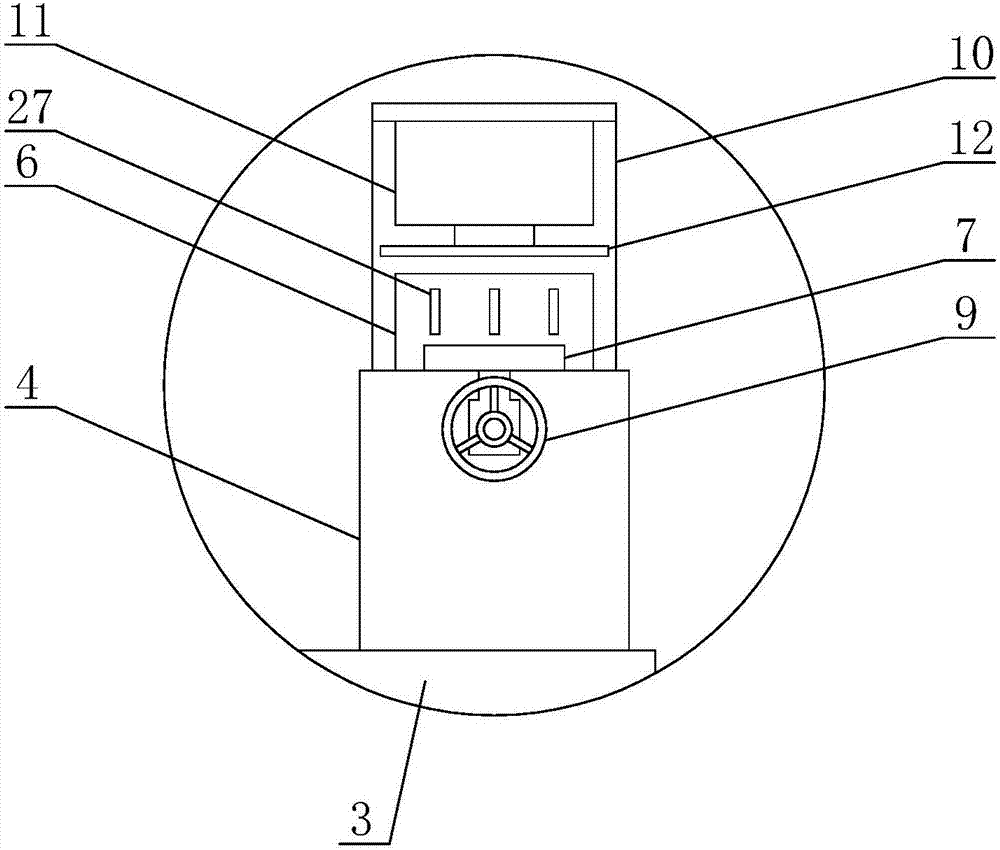

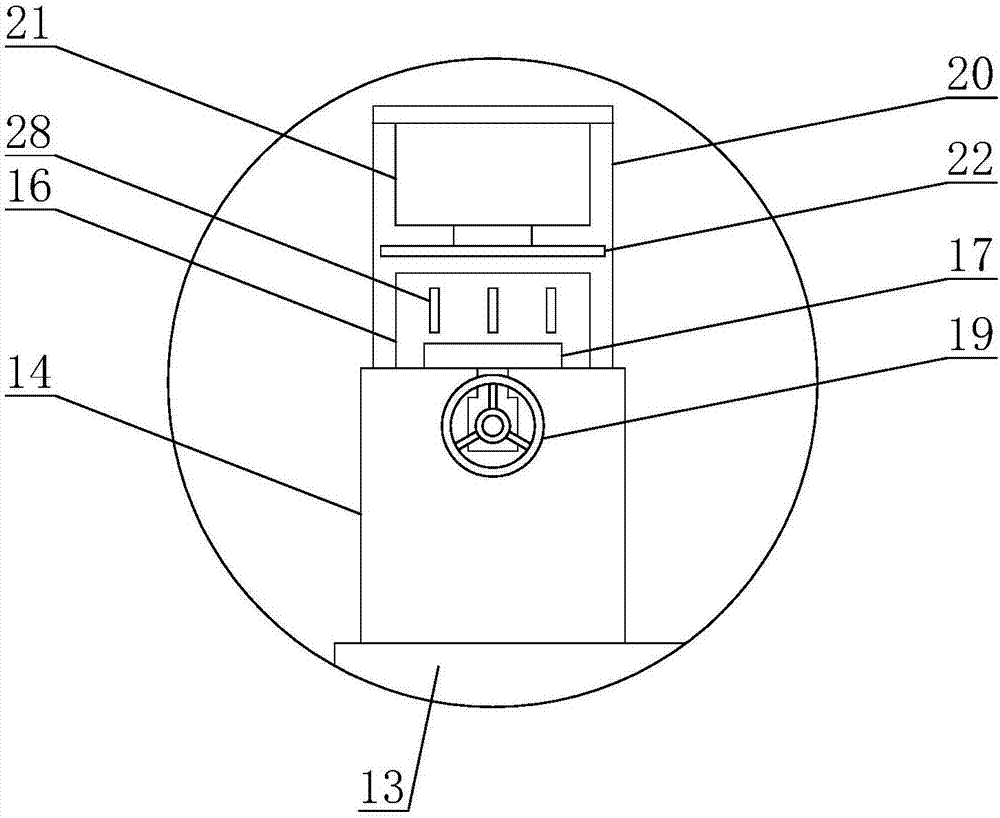

[0026] Embodiment: The present invention is a butt welding machine for construction engineering, which includes a frame 1, which is a bracket welded by square tubes, and a horizontal support plate is welded on the top of the bracket. The top of the frame 1 is horizontally provided with a guide post 2, the number of the guide post 2 is two, the centerlines of the two guide posts 2 are parallel and located on the same horizontal plane, and one end of the guide post 2 is provided with a fixed seat 3 , the fixed base 3 is provided with a through hole compatible with the guide column 2, and the fixed base 3 is fixedly connected with the guide column 2 through bolts. The top of the fixed seat 3 is provided with a first support seat 4, the first support seat 4 is fixed on the fixed seat 3 by a hexagon socket bolt, and the top of the first support seat 4 is provided with several first V-shaped grooves 5 , the first V-shaped groove 5 is used to place steel bars or steel pipes. The siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com