Jack catch for clamping workpiece or cutting tool

A cutting tool and workpiece technology, applied in the field of clamping devices, can solve the problems of difficult processing and large cutting volume of helical teeth, and achieve the effect of simple structure, small processing area and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

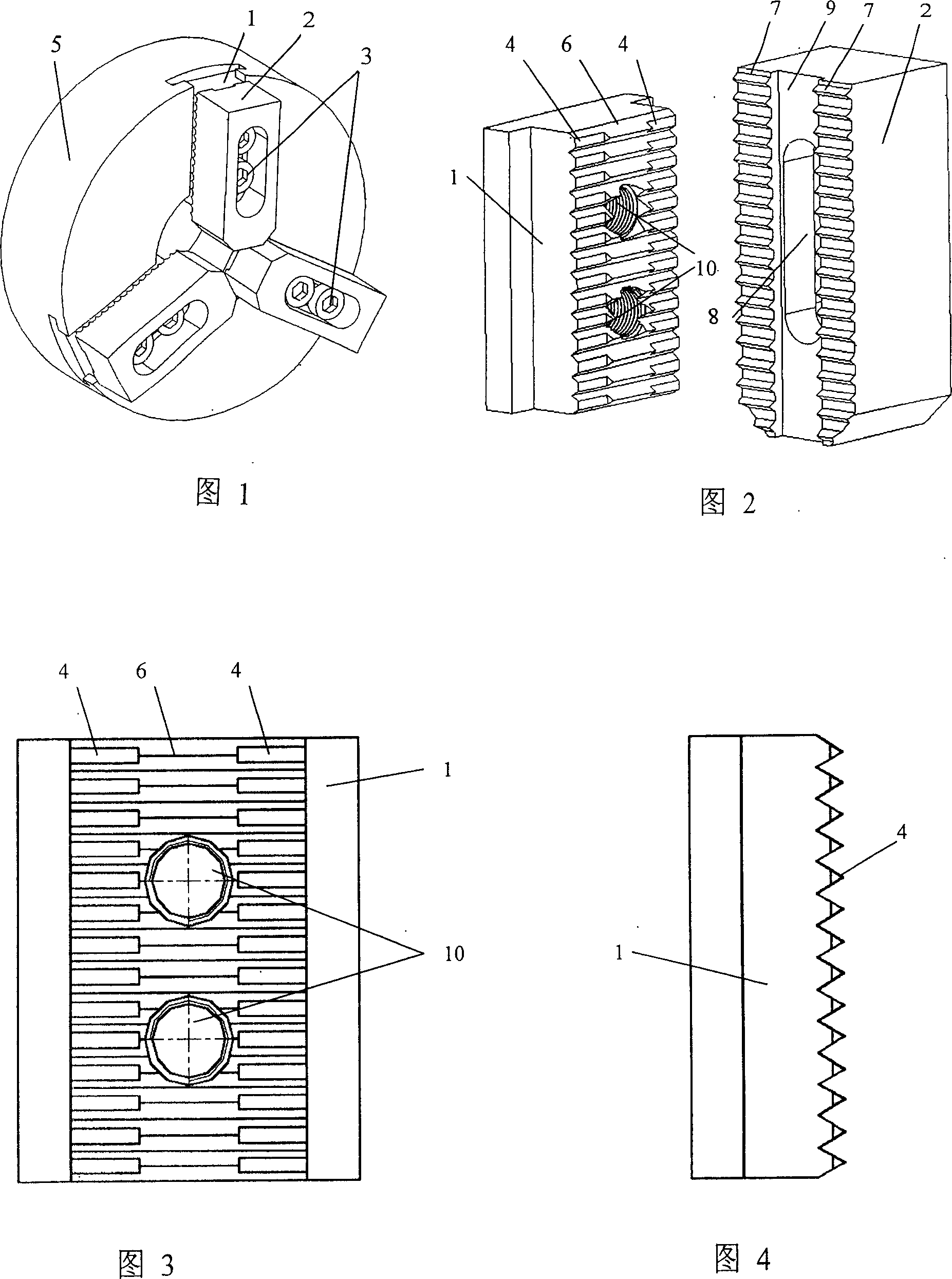

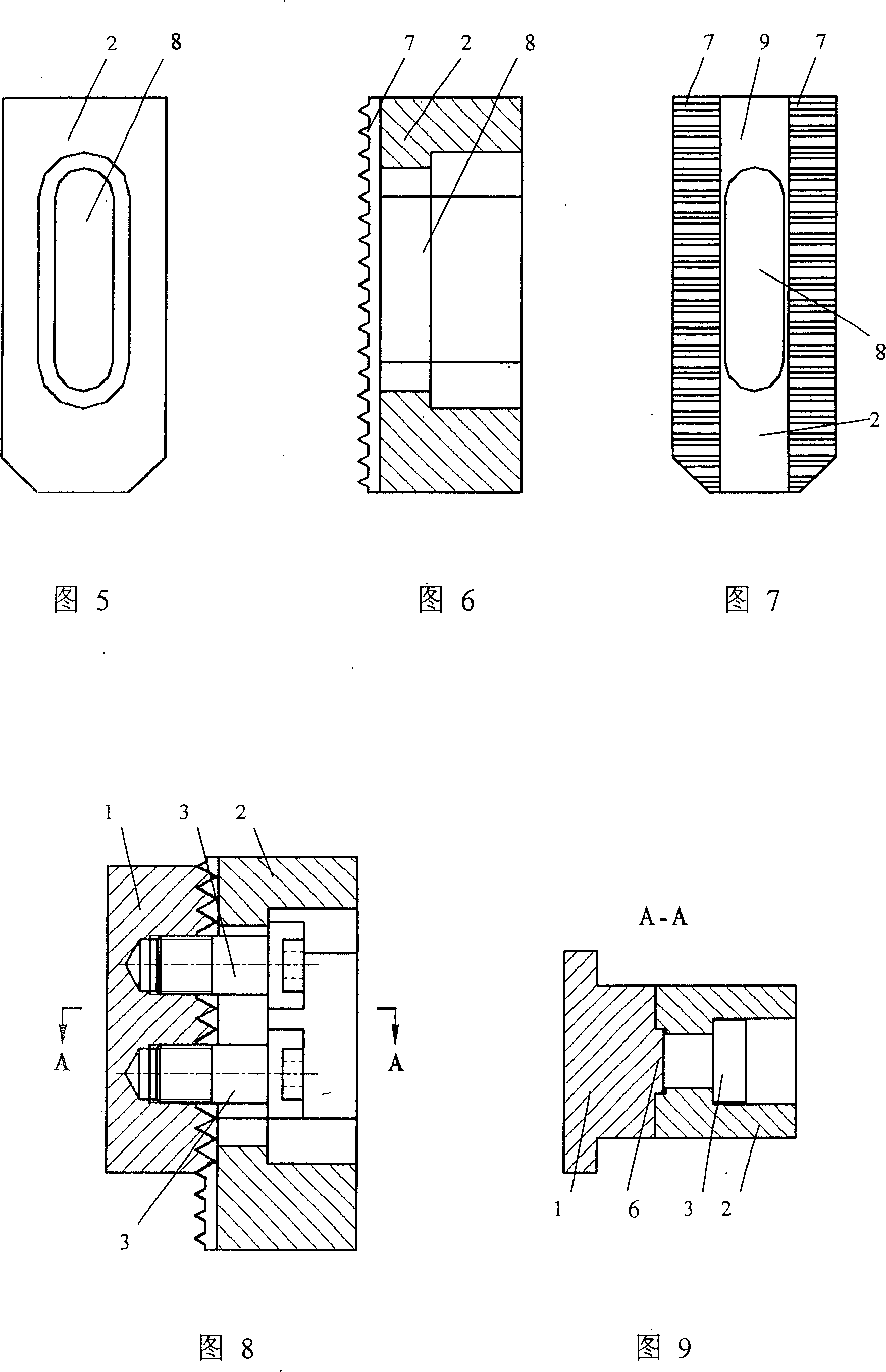

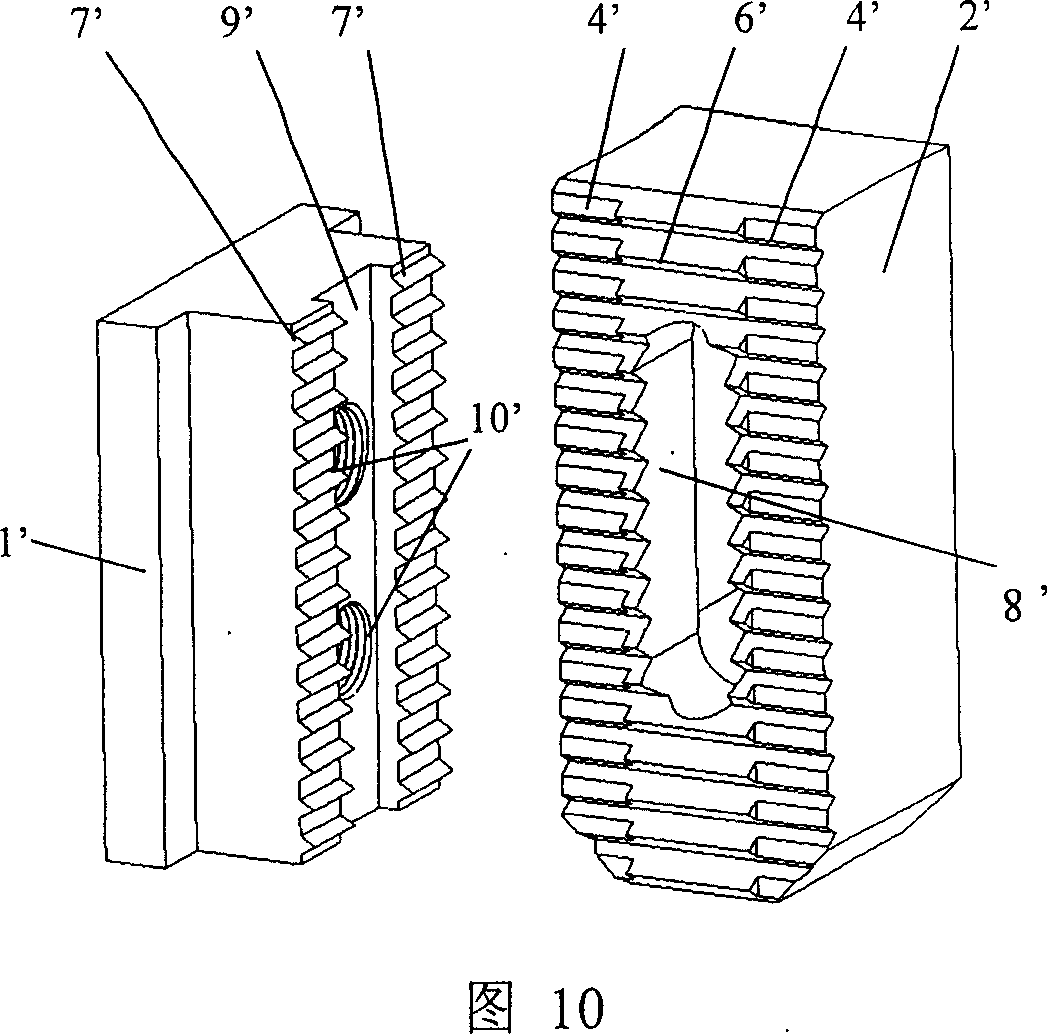

[0018] The present invention will be further illustrated by the accompanying drawings and examples.

[0019] As shown in Figures 1 to 9, the present invention includes a toothed base claw 1 matched with a toothed high claw 2, and connected with a screw 3 as a whole. One side of the base claw 1 is provided with base claw triangular teeth 6 arranged equidistantly, and the tooth tops on both sides of the base claw triangular teeth 6 are flattened into base claw trapezoidal teeth 4, and the base claw triangular teeth 6 in the middle of the base claw 1 are provided with base claw screws Hole 10, one side of the high claw 2 is provided with the same pitch as the base claw 1, and the tooth top is triangular, and the tooth groove is trapezoidal high claw teeth 7, and the middle of the toothed side of the high claw 2 is provided with a horizontal positioning groove for the high claw 9. There is a high claw waist-shaped hole 8 parallel to the high claw lateral positioning groove 9 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com