Electrochemical cell and preparation method thereof

An electrochemical and battery technology, applied in the field of electrochemical batteries, can solve problems such as vulnerability to damage and poor performance of flexible batteries, and achieve the effects of improving energy density, increasing and reducing electrode impedance, and solving packaging reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

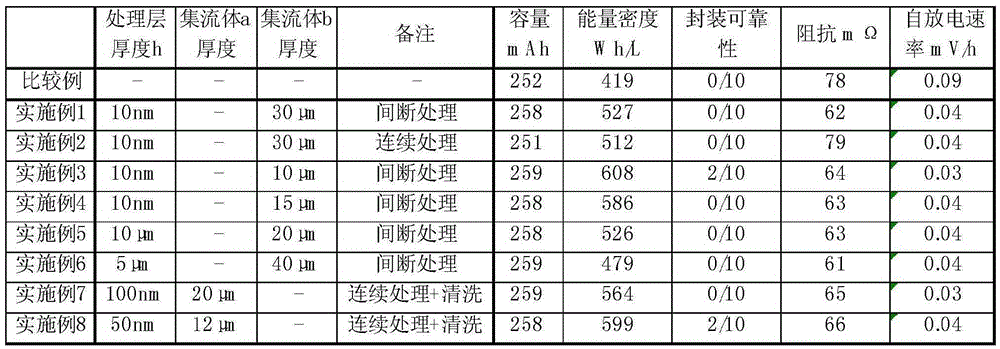

Embodiment 1

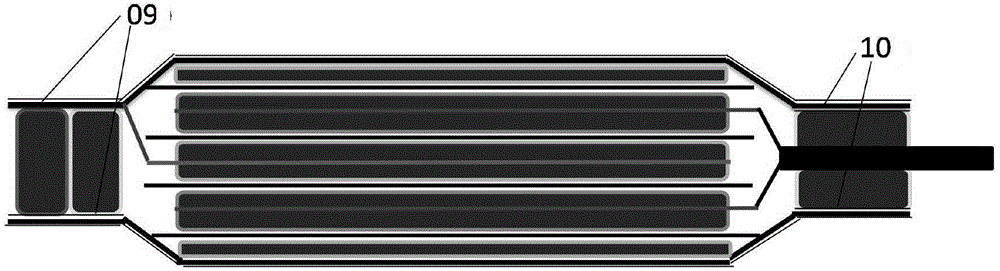

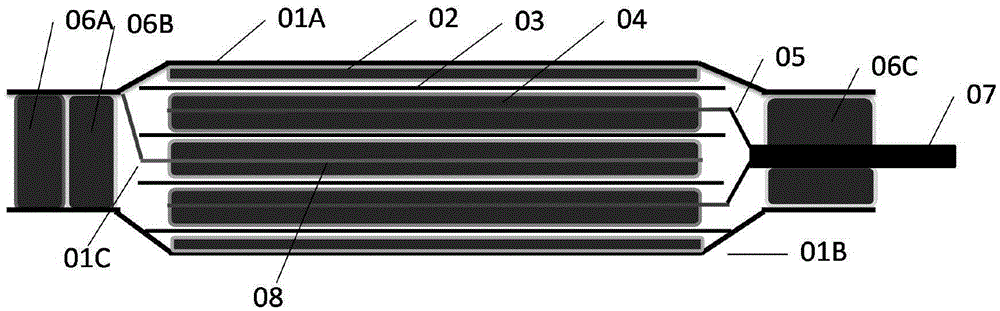

[0040] figure 1 Shown is the schematic diagram of the cross-sectional structure of the electrochemical cell corresponding to this embodiment. It can be seen from the figure that the negative electrode coating 02 is coated on one surface of the current collector 01A as the packaging material, and then coated with the separator 03 and double-sided coating There are five layers of electrodes in total (three negative electrodes, two positive electrodes, two of the three negative electrodes are single-sided coated, one is double-sided coated, and the two positive electrodes are double-sided coated. The positive electrode sheet is welded together with the current collector 07 through the current collector cutting lug 05, and is connected to the outside of the cell by the current collector 07. The current collectors 01A and 01B are water-proof layers in the packaging structure. The insulating sealing layer 06C bonds the water-blocking layer 01A and 01B together to seal and insulate t...

Embodiment 2

[0048] The difference from Example 1 is that it includes the following steps:

[0049] Auxiliary treatment of current collector packaging: put chromium solution in the electroplating tank, spread copper foil with a thickness of 30 μm on the surface of the electroplating tank, and perform electroplating to obtain a chromium-containing packaging auxiliary treatment layer with a thickness of 10 nm, and then wash it with deionized water , to obtain the current collector after encapsulation auxiliary treatment for use;

[0050] Negative electrode preparation as a packaging structure: apply the above-mentioned negative electrode slurry on the current collector after the above-mentioned auxiliary encapsulation treatment to obtain a single-sided coated electrode sheet, and then wash off the coating corresponding to the sealing area with deionized water, and separate After cutting, the negative electrode electrode coated on one side of the monolithic sheet is obtained for use;

[0051...

Embodiment 3

[0053] The difference from Example 1 is that it includes the following steps:

[0054] Auxiliary treatment of current collector packaging: place the chromium solution in the electroplating tank with a fixed structure (the electroplating tank is a "ten" cross groove, of which only the "cross" line is the chromium liquid containing tank, and the groove width matches the seal width (equal to seal width)), and then spread copper foil with a thickness of 10 μm on the surface of the electroplating tank for electroplating to obtain a chromium-containing packaging auxiliary treatment layer with a thickness of 10 nm. The chromium-containing packaging auxiliary treatment layer divides the current collector into multiple uncoated The treated current collector small pieces are then cleaned with deionized water to obtain the packaged auxiliary treated current collector for use;

[0055] The rest are the same as in Embodiment 1 and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com