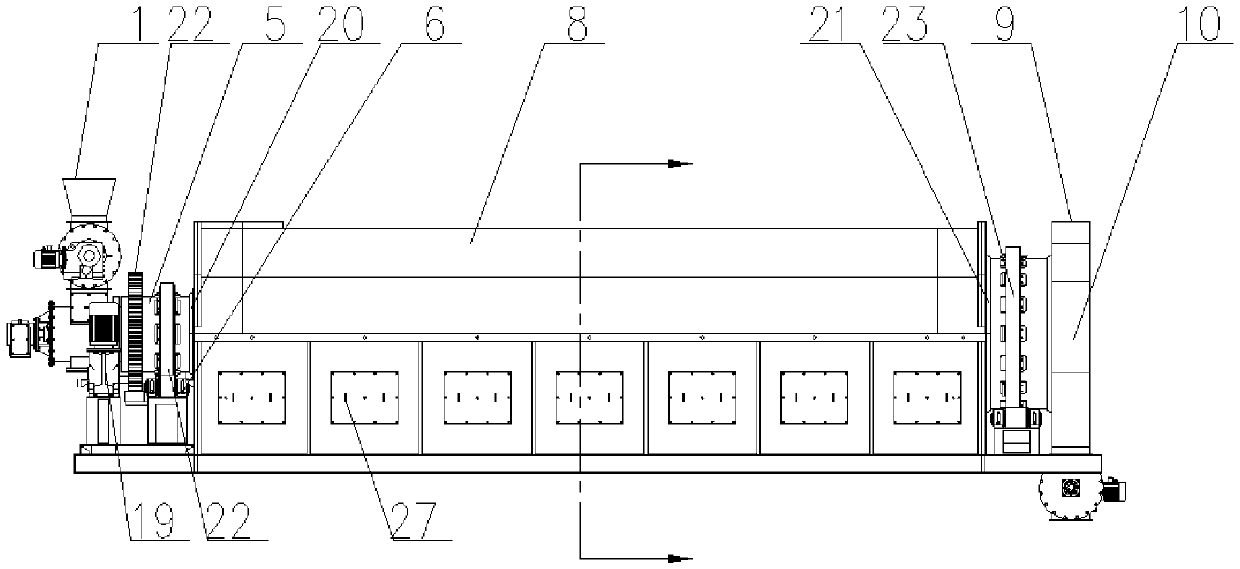

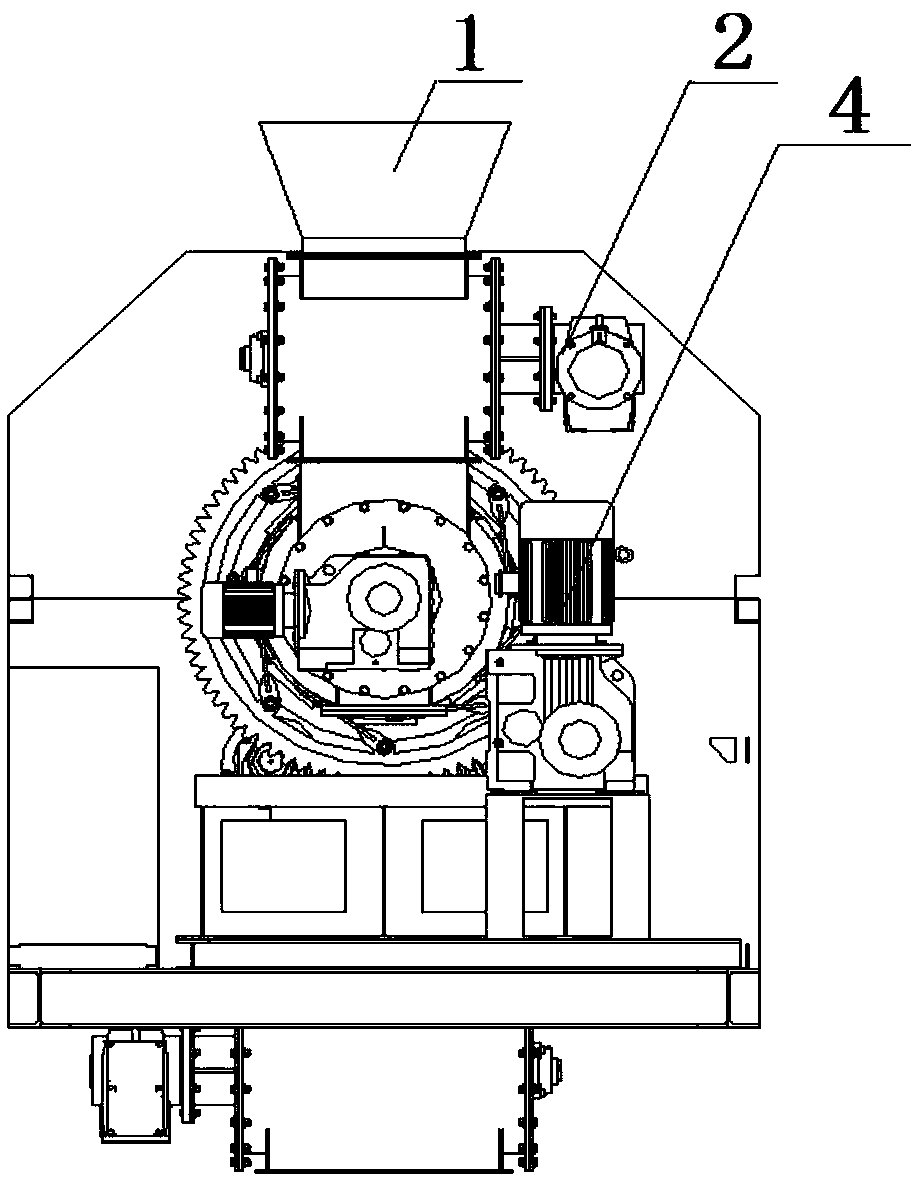

External thermal rotary organic contaminated soil thermal desorption device with inner tube bundle

A technology of organic pollution and thermal rotation, which is applied in the field of soil remediation of contaminated sites, and can solve the problems of large footprint, low processing capacity of a single machine, and low thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] The above-mentioned device is used to treat organic pollutants, and its specific parameter conditions are shown in Table 1.

[0080] Processing object:

[0081] Moisture content 20%, toluene, xylene volatile organic pollution soil treatment parameters:

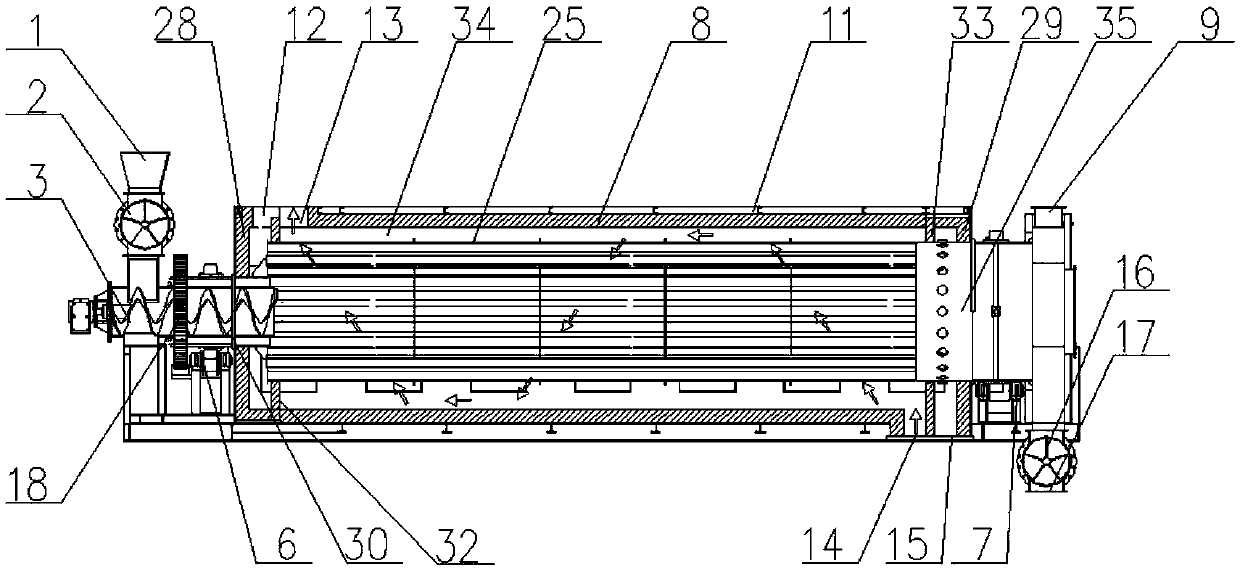

[0082] The temperature of the flue gas inlet (16) inside the tube is 650 °C, the temperature of the flue gas inlet (14) outside the tube is 700 °C, and the soil residence time is 30 minutes, the temperature of the flue gas outlet (15) of the tube bundle is 220 °C, and the flue gas outlet (13) outside the tube is 220 °C. The temperature is 260°C, the treatment capacity is 7.4t / h, the initial average concentration of toluene and xylene is 500mg / kg, the average concentration after treatment is lower than 5.0mg / kg, the removal rate has reached 99%, and the average heating per ton of soil consumption 40Nm 3 / h natural gas;

[0083] The temperature of the flue gas inlet (16) inside the tube is 700 °C, the temperature of th...

Embodiment 2

[0085] The above-mentioned device is used to treat organic pollutants, and its specific parameter conditions are shown in Table 1.

[0086] With a moisture content of 20%, the treatment parameters of semi-volatile organic polluted soil by 666 and DDTs pesticides:

[0087] The temperature of the flue gas inlet (16) inside the cylinder is 700°C, the temperature of the flue gas inlet (14) outside the cylinder is 750°C, and when the soil residence time is 30 minutes, the temperature of the flue gas outlet (12) inside the cylinder is 260°C, and the temperature of the flue gas outlet (13) outside the cylinder is 260°C. ) temperature is 300°C, the treatment capacity is 7.4t / h, the initial average concentration of HC6 and DDTs is 300mg / kg, the average concentration after treatment is lower than 6.0mg / kg, the removal rate has reached 98%, and the average heating per ton Soil consumption 45Nm 3 / h natural gas;

[0088]The temperature of the flue gas inlet (16) inside the cylinder is 7...

Embodiment 3

[0090] The above-mentioned device is used to treat organic pollutants, and its specific parameter conditions are shown in Table 1.

[0091] Moisture content 20%, benzoanthracene, benzopyrene polycyclic aromatic hydrocarbons refractory volatile organic pollution soil treatment parameters:

[0092] The temperature of the flue gas inlet (16) inside the cylinder is 750°C, the temperature of the flue gas inlet (14) outside the cylinder is 800°C, and the soil residence time is 30 minutes, the temperature of the flue gas outlet (12) inside the cylinder is 300°C, and the temperature of the flue gas outlet (13) outside the cylinder is 300°C. ) temperature is 340°C, the treatment capacity is 7.4t / h, the initial average concentration of benzoanthracene and benzopyrene is 100mg / kg, the average concentration after treatment is lower than 2.0mg / kg, the removal rate has reached 98%, and the average heating Consumption of 50Nm per ton of soil 3 / h natural gas;

[0093] The temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com