Oil spouting ignition apparatus

A fuel injector and igniter technology, which is applied to electric spark ignition controllers, engine ignition, spark plugs, etc., can solve the problems of high requirements for the processing of fuel injector mounting holes, difficult fuel injector installation and layout, and increased engine cost. Achieve the effect of favorable fuel atomization, compact structure, and reduced number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

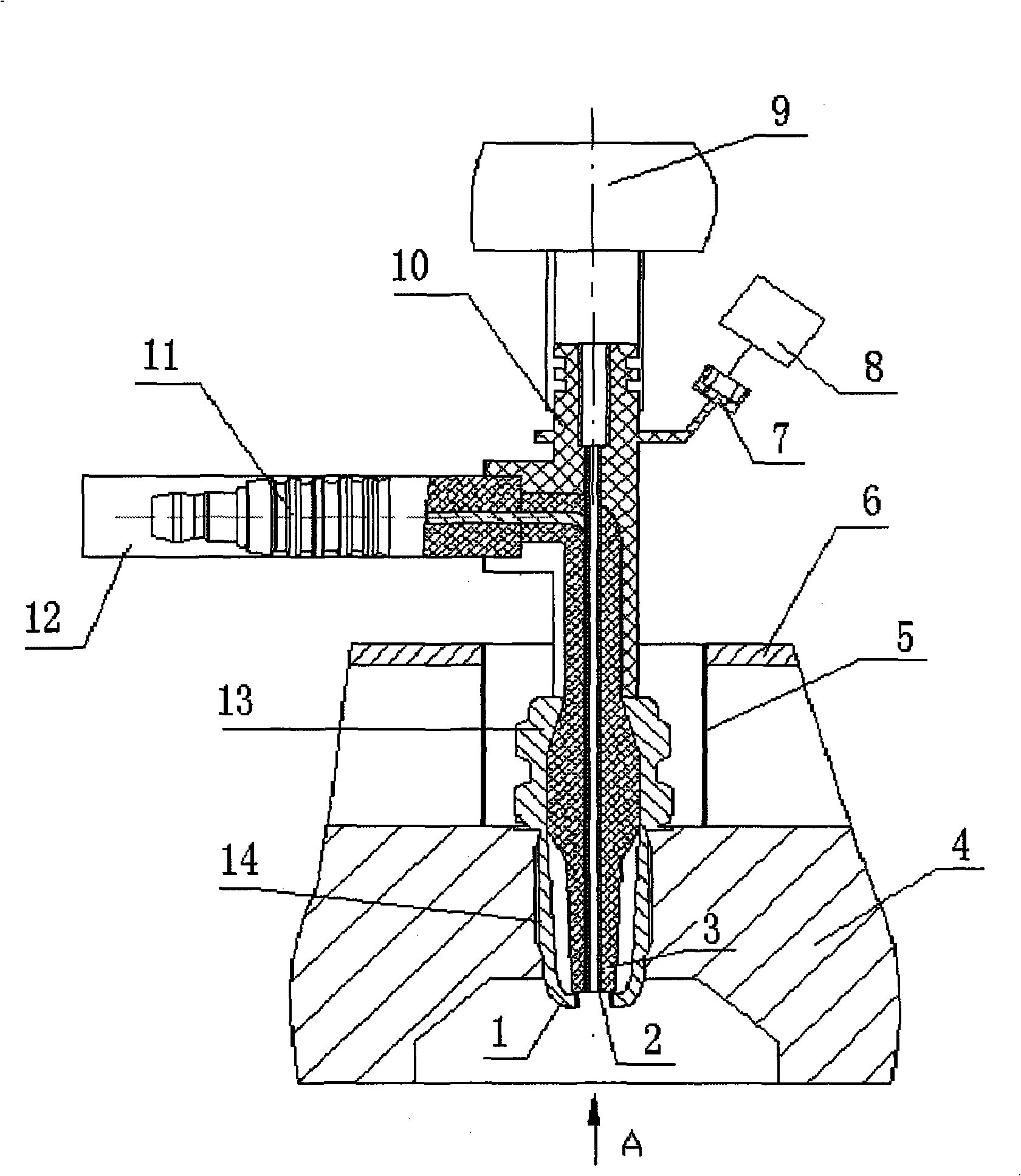

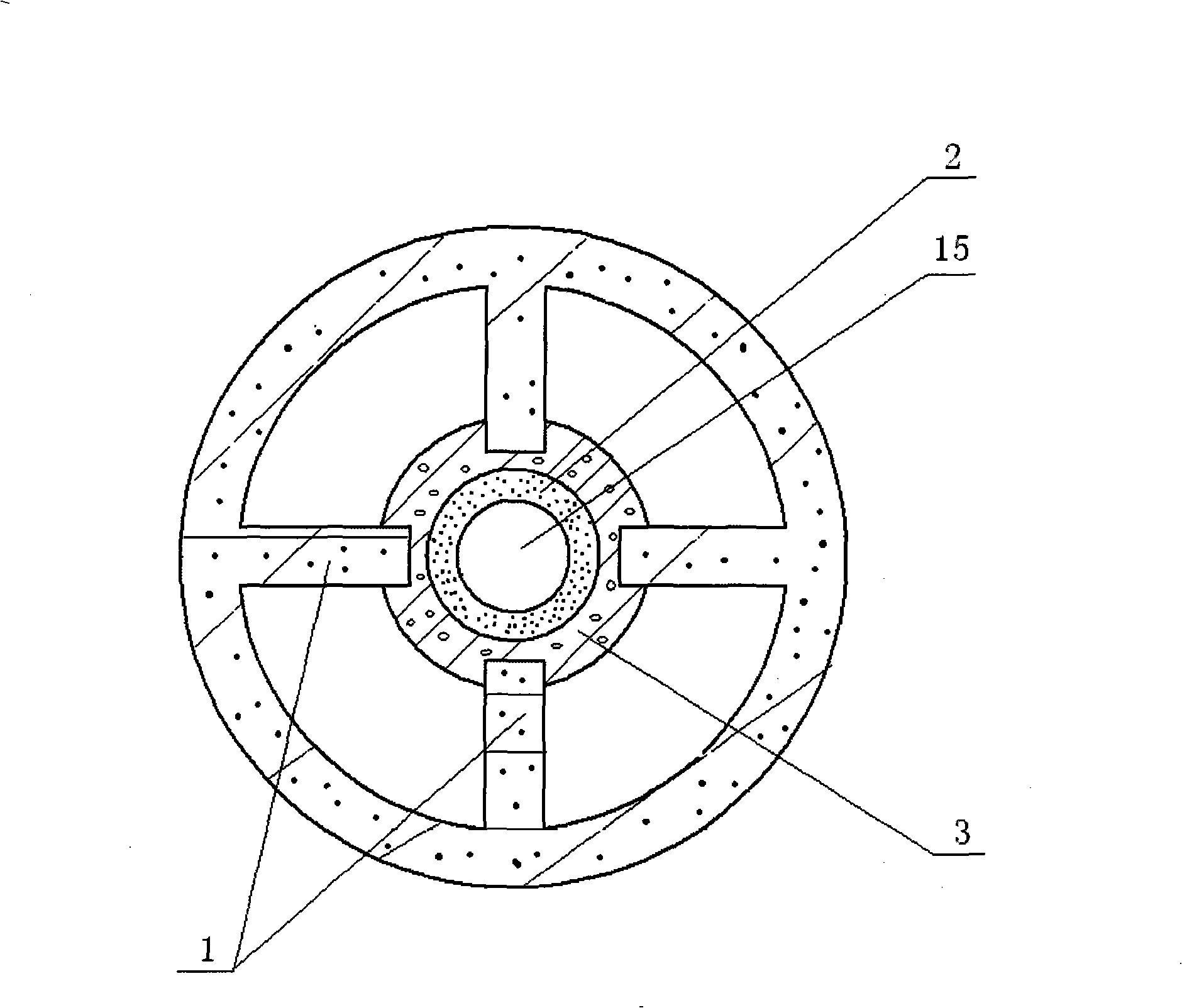

[0017] Such as figure 1 , figure 2 As shown, a fuel injection igniter includes a fuel rail 9, a cylinder head 4, an fuel injector 10, and a spark plug 11. The spark plug 11 includes a center electrode 2, an insulator 3, and four side electrodes 1. The insulator 3 wraps the center electrode 2 , The fuel injector 10 and the spark plug 11 are integrated, and the lower part of the fuel injector 10 overlaps with the lower part of the spark plug 11. The angle between the center line of the fuel injector 10 and the center line of the upper part of the spark plug 11 is 90 degrees, and the upper end of the fuel injector 10 In communication with the fuel rail 9, the lower end of the fuel injector 10 extends vertically into the center of the combustion chamber, and the middle of the fuel injector 10 has a copper core as the center electrode 2 of the spark plug 11, and the copper core is a piece with a fuel injection hole 15 A slender tube, the upper electrode of the spark plug 11 is in cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com