Sintered brick prepared by utilizing paper mill sludge and preparation method thereof

A technology of papermaking sludge and sintered bricks, which can be used in applications, clay products, household appliances, etc., can solve the problems of high cost and unsuitable promotion, and achieve the effects of low price, good heat insulation, and solving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] The invention is a fired brick prepared by papermaking sludge. The fired brick consists of 7 parts of clay, 2 parts of coal gangue and 1 part of sludge in parts by weight. Its size is 240mm x 115mm x 53mm. The sludge is the sludge produced after the wastewater discharged from the production system of the paper mill is treated.

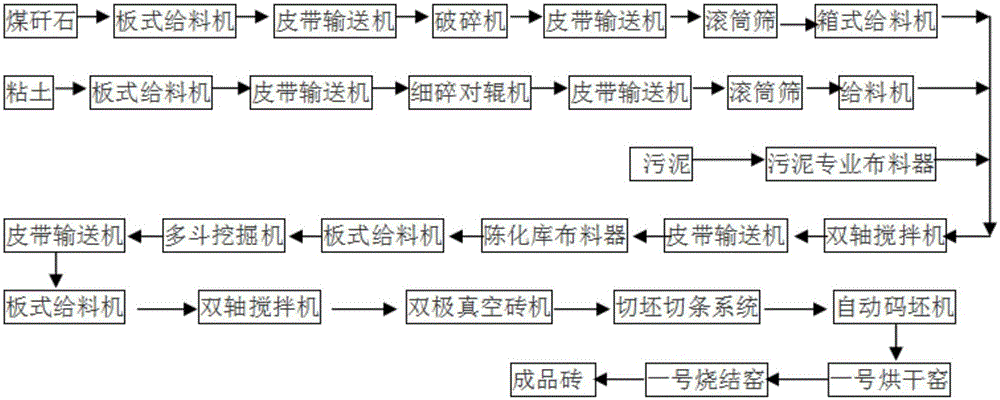

[0018] Such as figure 1 As shown, another object of the present invention is to provide a method for preparing sintered bricks from papermaking sludge, comprising the following steps: 1. Crushing and filtering coal gangue and feeding it into a coal gangue feeder; 2. Crushing and filtering the clay 3. Fully mix the sludge with the treated coal gangue and clay in a fixed ratio through a feeder to obtain raw materials, and make billets, dry and sinter the mixed raw materials to obtain finished products .

[0019] The gangue feeder is ...

PUM

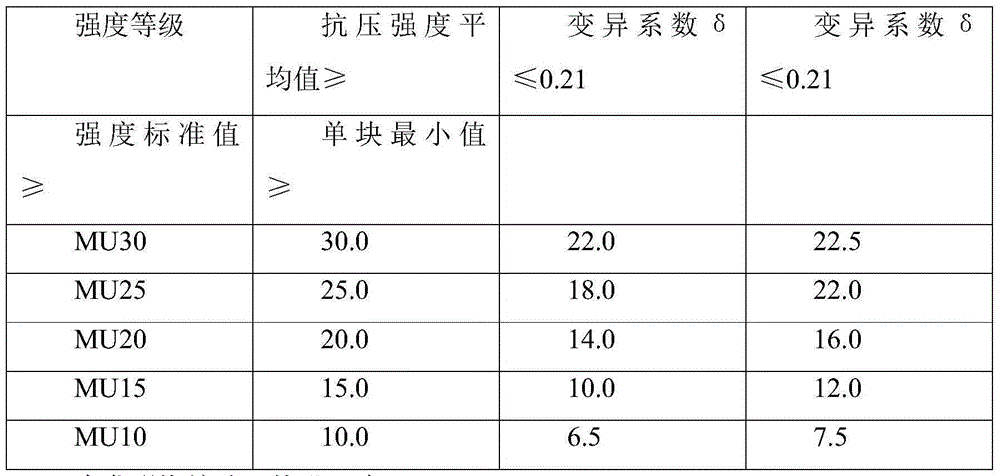

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com