Cold region livestock and poultry breeding sewage treatment method

A sewage treatment method and livestock and poultry breeding technology, applied in the field of sewage treatment, can solve problems such as water pollution, and achieve the effects of short process flow, low production cost, and reduced planting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

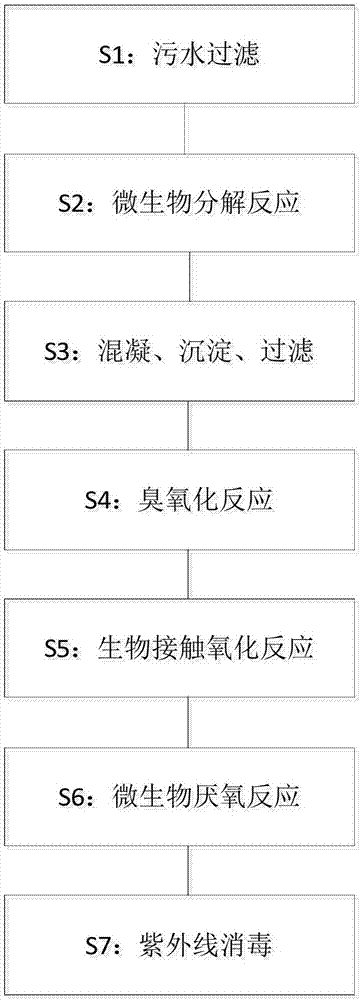

Method used

Image

Examples

Embodiment 1

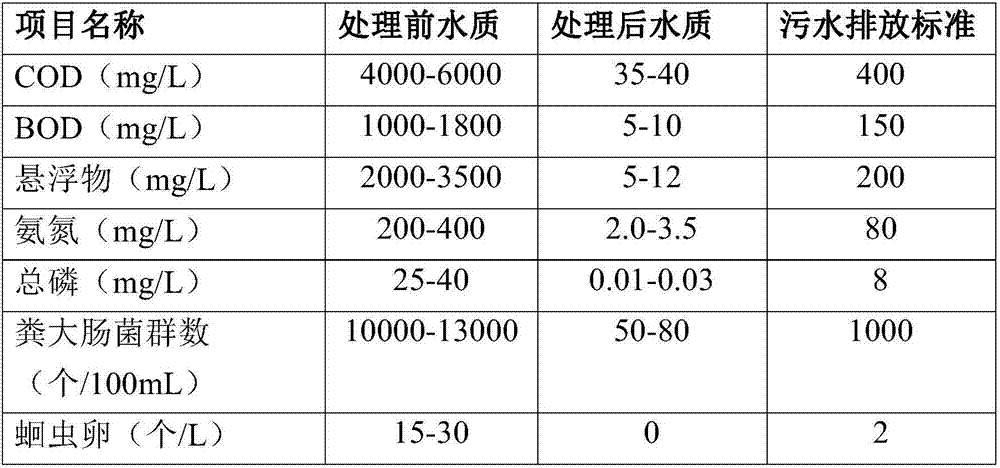

[0042] Treatment of farm sewage with 10,000 broiler chickens in breeding scale:

[0043] S1: Flow the sewage to the filter tank, use stainless steel 20-mesh, 40-mesh and 60-mesh filter screens at the water inlet, middle and outlet of the filter tank to filter, step by step filtration can fully remove the filter residue in the sewage, and get filtered treated water. The filtered residue can be used as crop fertilizer after being dried and pulverized, reducing the planting cost of farmers.

[0044] S2: Put 10 parts of nitrifying bacteria, 20 parts of photosynthetic bacteria, 20 parts of Bacillus subtilis, 10 parts of lactic acid bacteria, 10 parts of yeast, 5 parts of actinomycetes, 5 parts of Bdellovibrio, and 10 parts of EM bacteria into the filtered water , 5 parts of cellobiose-producing Clostridium, 2 parts of mutual oxygen bacteria, reacted for 3 days to obtain purified water. In this step, a variety of microorganisms are used to work together, which can be mutually bene...

Embodiment 2

[0051] Treatment of farm sewage with 5,000 pigs in breeding scale:

[0052] S1: Flow the sewage to the filter tank, use stainless steel 20-mesh, 40-mesh and 60-mesh filter screens at the water inlet, middle and outlet of the filter tank to filter, step by step filtration can fully remove the filter residue in the sewage, and get filtered treated water. The filtered residue can be used as crop fertilizer after being dried and pulverized, reducing the planting cost of farmers.

[0053] S2: Put 10 parts of nitrifying bacteria, 20 parts of photosynthetic bacteria, 20 parts of Bacillus subtilis, 10 parts of lactic acid bacteria, 10 parts of yeast, 5 parts of actinomycetes, 5 parts of Bdellovibrio, and 10 parts of EM bacteria into the filtered water , 5 parts of cellobiose-producing Clostridium, 2 parts of mutual oxygen bacteria, reacted for 4 days to obtain purified water. In this step, a variety of microorganisms are used to work together, which can be mutually beneficial in the...

Embodiment 3

[0060] Treatment of farm sewage with 300 beef cattle in breeding scale:

[0061] S1: Flow the sewage to the filter tank, use stainless steel 20-mesh, 40-mesh and 60-mesh filter screens at the water inlet, middle and outlet of the filter tank to filter, step by step filtration can fully remove the filter residue in the sewage, and get filtered treated water. The filtered residue can be used as crop fertilizer after being dried and pulverized, reducing the planting cost of farmers.

[0062] S2: Put 10 parts of nitrifying bacteria, 20 parts of photosynthetic bacteria, 30 parts of Bacillus subtilis, 10 parts of lactic acid bacteria, 15 parts of yeast, 5 parts of actinomycetes, 5 parts of Bdellovibrio, 15 parts of EM bacteria into the filtered water , 5 parts of cellobiose-producing Clostridium, 3 parts of mutual oxygen bacteria, reacted for 5 days to obtain purified water. In this step, a variety of microorganisms are used to work together, which can be mutually beneficial in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com