Production method for synthesizing ammonium bicarbonate fertilizer by using CO2 waste gas

A production method and technology for synthesizing carbon, applied in the direction of separation methods, chemical instruments and methods, products, etc., can solve the problems of low waste gas treatment efficiency, accelerated global warming, etc., and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

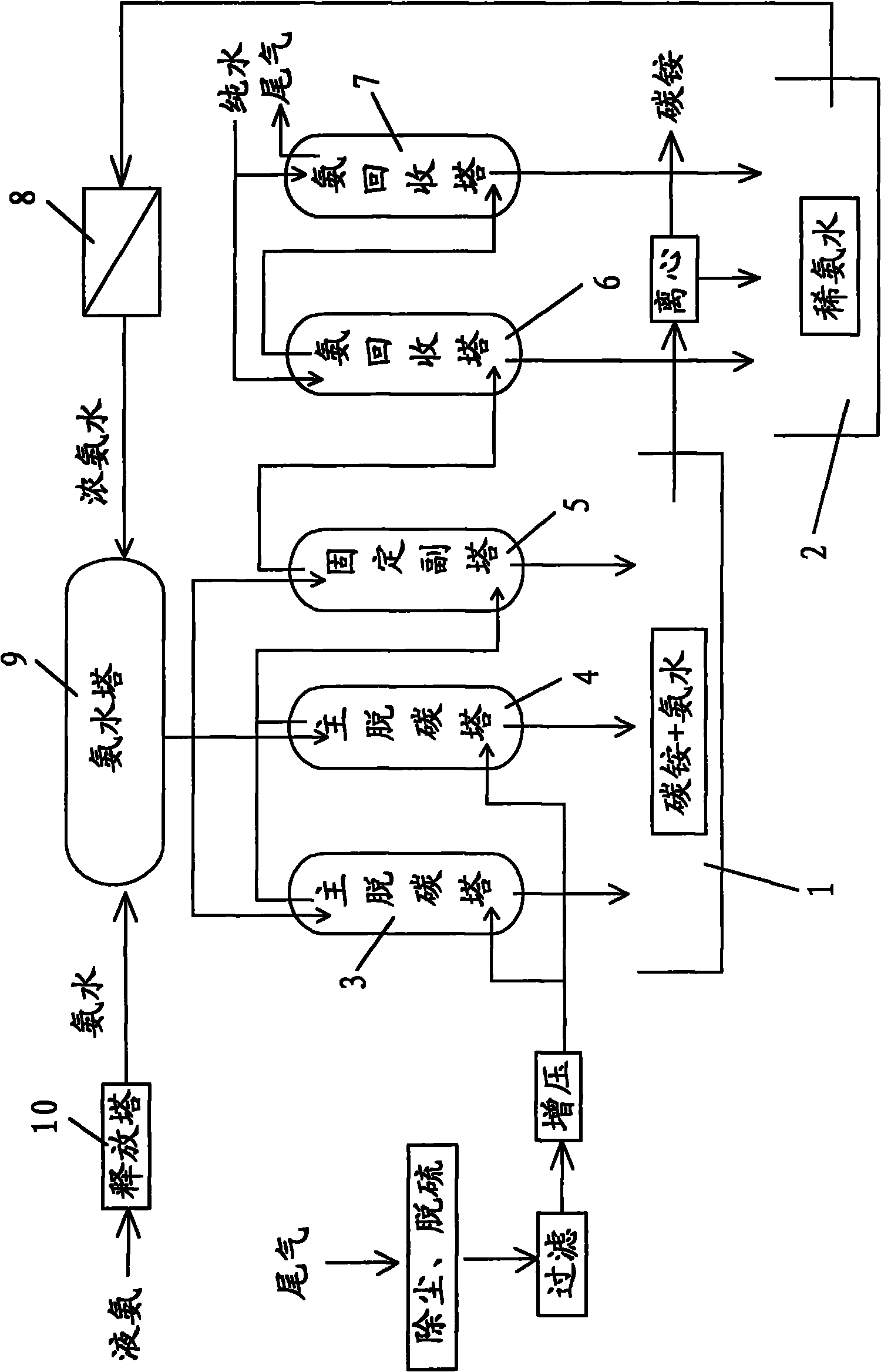

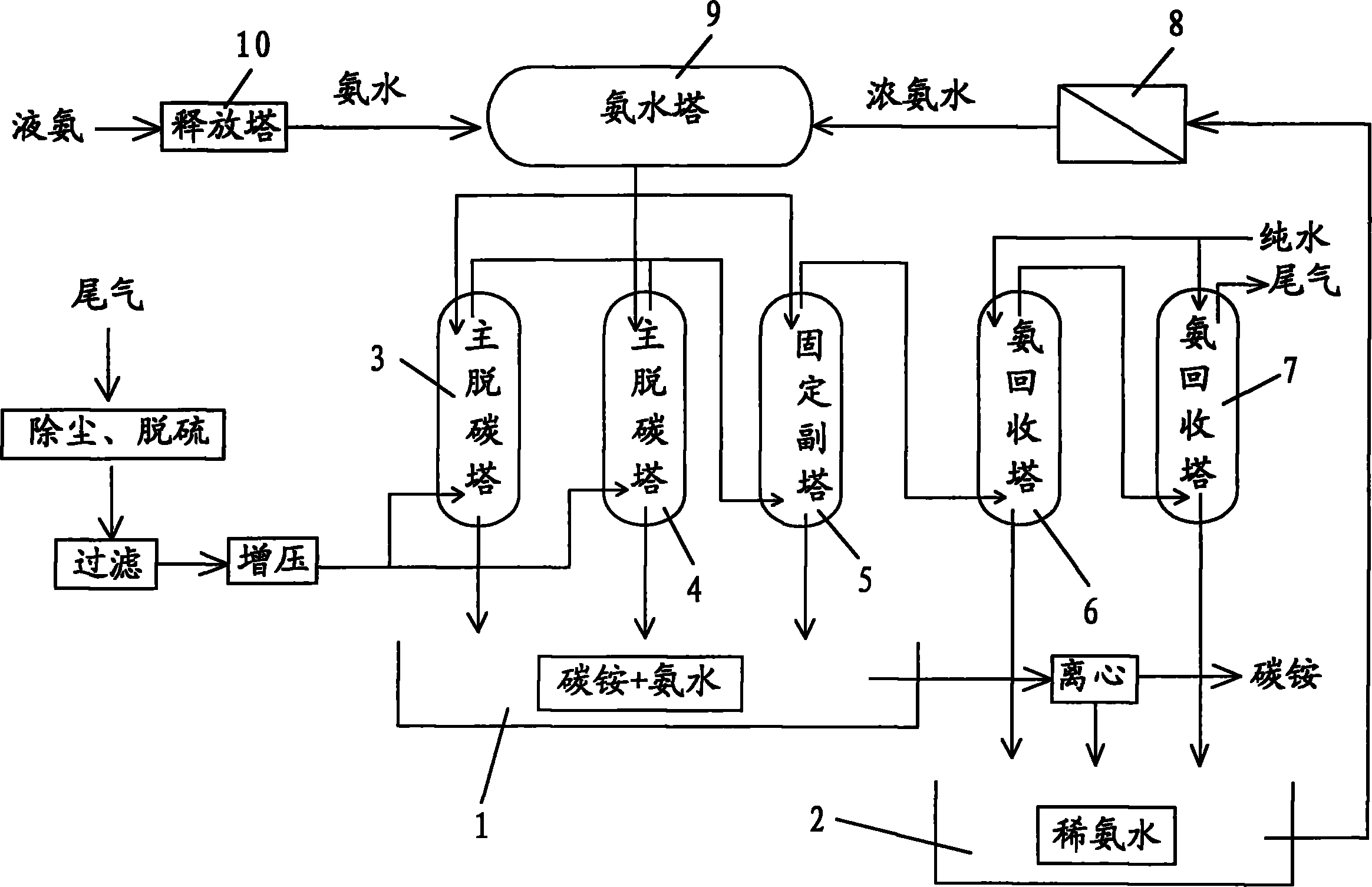

[0021] Embodiment: a kind of utilizing CO 2 The technological process of waste gas synthesis of ammonium bicarbonate fertilizer is attached figure 1 Shown: After being further filtered by filter cloth for dust removal and desulfurization, the exhaust gas enters two parallel main decarbonization towers 3 and 4 after being pressurized, and enters from the bottom of the main decarbonization tower from bottom to bottom; The liquefied ammonia released from the tower 10 enters from the main decarbonization towers 3, 4 and the fixed sub-tower 5 by spraying from top to bottom through pipelines, and the CO 2 The gas is fully contacted, and the reaction produces ammonium bicarbonate crystals. Ammonium bicarbonate crystals and remaining ammoniacal liquor are collected in the pool 1 through the pipeline.

[0022] The mixture of ammonium bicarbonate and ammonia water in pool 1 is separated by centrifugation to obtain ammonium bicarbonate crystals and dilute ammonia water, which is collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com