Zero emission treatment method and special treatment system for reverse osmosis concentrated water difficult to decompose

A technology of reverse osmosis concentrated water and treatment system, which is applied in the field of zero discharge treatment method and special treatment system of refractory reverse osmosis concentrated water, which can solve the problems of high cost, inability to achieve zero discharge treatment, cumbersome and complicated treatment steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

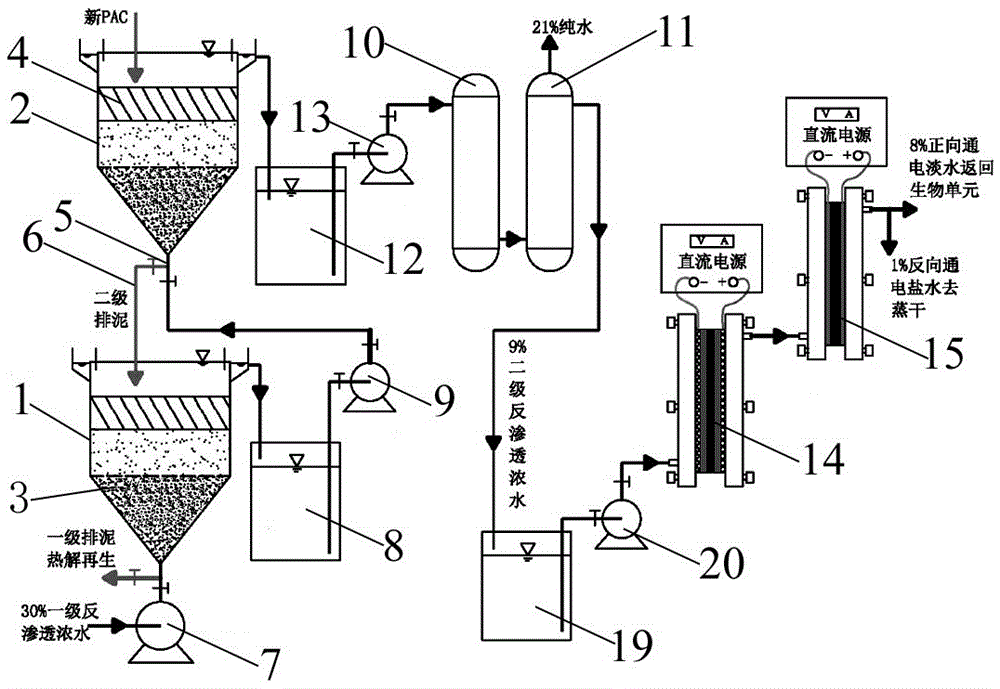

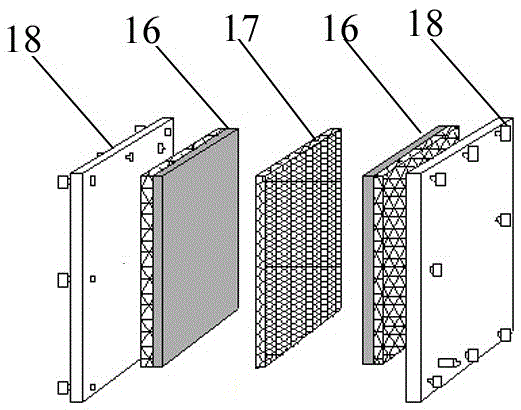

[0039] Such as figure 1 As shown, the patented zero discharge treatment system for refractory reverse osmosis concentrated water provided by the present invention includes an activated carbon adsorption unit, an ultrafiltration-reverse osmosis unit and an electrochemical treatment module.

[0040] Wherein the activated carbon adsorption unit comprises a primary activated carbon filter bed 1 and a secondary activated carbon filter bed 2; the secondary activated carbon filter bed 2 is arranged downstream of the primary activated carbon filter bed 1; the primary activated carbon filter bed 1 and the secondary activated carbon filter bed 2 are both It is set as a funnel-shaped cylinder at the bottom, with a water inlet at the lower end and a water outlet at the upper end of the cylinder, and a powdered activated carbon adsorption layer 3, a primary activated carbon filter bed 1 and a secondary activated carbon filter bed are provided inside the cylinder 2 are countercurrent adsorp...

Embodiment 2

[0052] The refractory reverse osmosis concentrated water is processed through the special treatment system prepared in Example 1, and its specific treatment steps are as follows:

[0053] (1) Adsorption treatment: Start the first water inlet pump, pump the refractory reverse osmosis concentrated water into the primary activated carbon filter bed 1 for adsorption, and the filtered water after the adsorption treatment of the primary activated carbon filter bed 1 flows out from the water outlet and Store in the first water storage tank 8; start the second water inlet pump 9, pump the filtered water in the first water storage tank 8 into the secondary activated carbon filter bed 2, and the filtered water after the adsorption treatment of the secondary activated carbon filter bed 2 from The water outlet flows out and is stored in the second water storage tank 12; the mass ratio of the refractory reverse osmosis concentrated water and powdered activated carbon consumption is 1800-200...

Embodiment 3

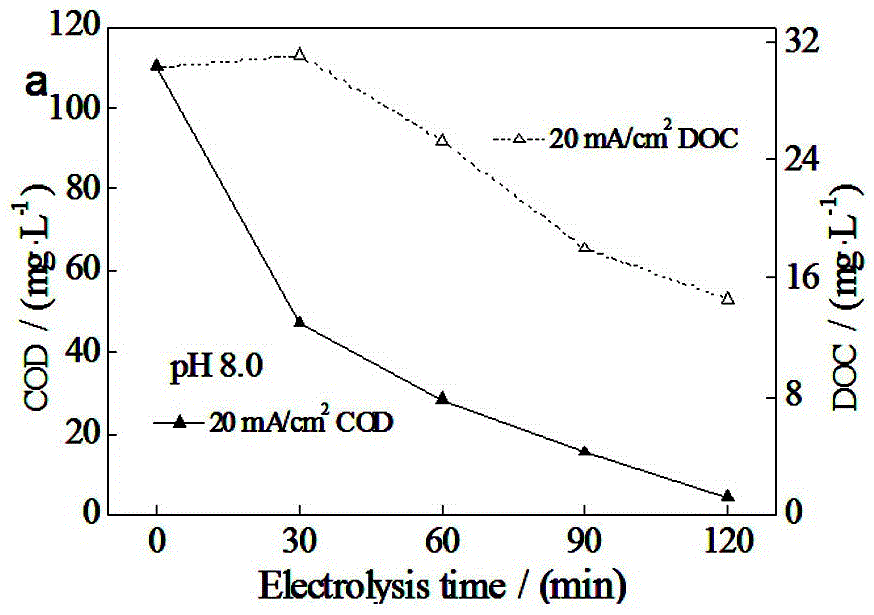

[0060] The professional treatment system prepared in Example 1 and the treatment method in Example 2 are used to treat the refractory reverse osmosis concentrated water filtered by double-membrane technology (i.e. ultrafiltration-reverse osmosis) in petrochemical enterprises. The initial COD is 132.0mg / L , pH value is 8.0, the changes of the refractory reverse osmosis concentrated water after each step of treatment and the final treatment results are shown in Table 1 and image 3 shown.

[0061] Table 1 Treatment process and treatment results of refractory reverse osmosis concentrated water with initial concentration of 132.0 mg / L and pH value of 8.0

[0062]

[0063] In Table 1, the effluent COD refers to the chemical oxygen demand in the treated wastewater, and the effluent DOC refers to the dissolved organic carbon in the treated wastewater.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com