Pulp residue treating and recycling system

A technology of pulping and slag machine, which is applied in fiber raw material treatment, pulp beating/refining method, textiles and papermaking, etc. It can solve the problems of increasing the organic content of sewage, increasing the load of sewage treatment, affecting the effect of sewage treatment, etc., and achieving reduction Organic matter content, low production cost, and effects of reducing processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

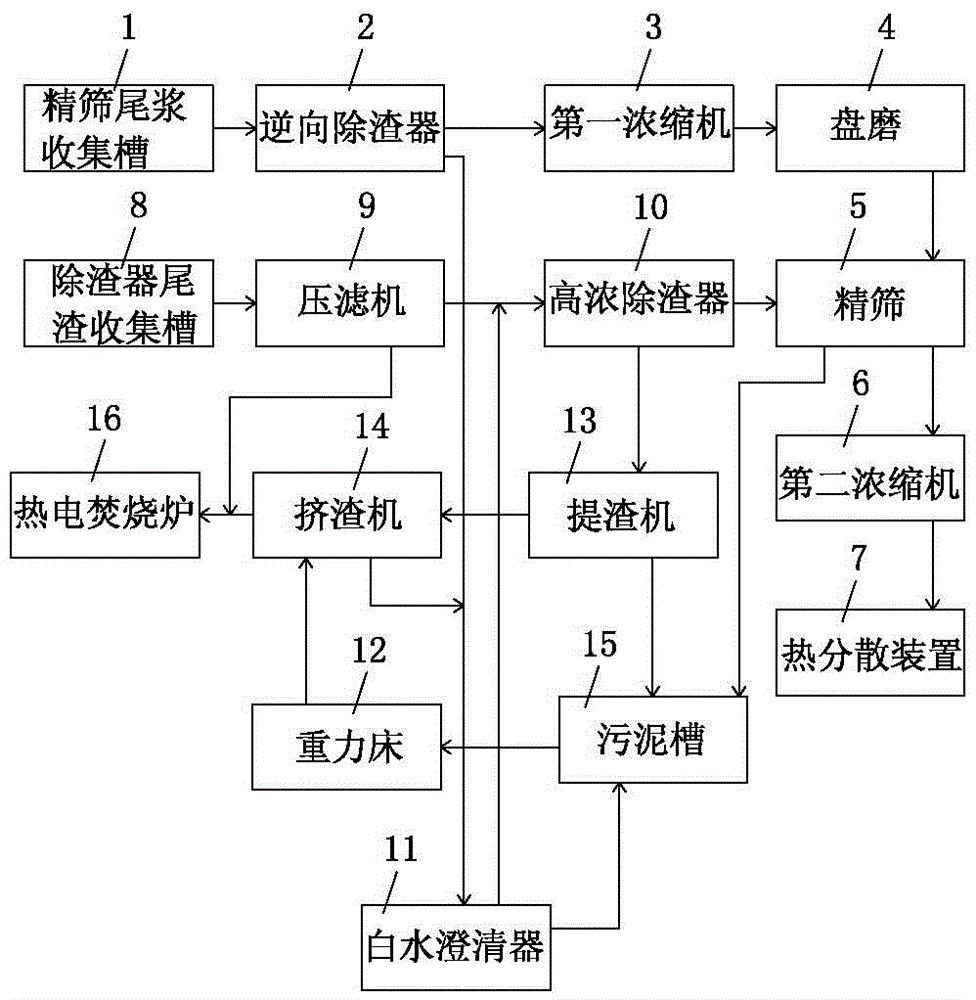

[0041] A kind of pulp slag processing recycling system of this embodiment, such as figure 1 As shown, it includes fine sieve tailings collection tank 1, reverse slag remover 2, first thickener 3, disc mill 4, fine sieve 5, second thickener 6, heat dispersion device 7, and slag remover tailings collection tank 8. Filter press 9, high-concentration slag remover 10, white water clarifier 11, gravity bed 12, slag extractor 13, slag extruder 14, sludge tank 15 and thermoelectric incinerator 16; among them, fine screen tailings are collected The fine screen tailings in the tank 1 are pumped to the reverse slag remover 2, the first output end of the reverse slag remover 2 is connected to the input end of the first concentrator 3, and the output end of the first concentrator 3 is connected to the disc mill 4 The input end is connected, the output end of the disc mill 4 is connected with the input end of the fine screen 5, the first output end of the fine screen 5 is connected with the...

Embodiment 2

[0049] Embodiment 2 of a pulp and residue treatment and recycling system of the present invention differs from Embodiment 1 in that, in this embodiment, the sieve width of the fine screen 5 is set to 0.2 mm. The fine sieve 5 with such a slit width can well separate non-fibrous components such as sand and fine ash in the tailings of the slag remover and the tailing slurry of the fine screen. Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0051]Embodiment 3 of a pulp and residue treatment and recycling system of the present invention differs from Embodiment 1 in that, in this embodiment, the sieve width of the fine screen 5 is set to 0.3 mm. The fine sieve 5 with such a slit width can well separate non-fibrous components such as sand and fine ash in the tailings of the slag remover and the tailing slurry of the fine screen. Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com