Combined absorption analytical method for hydrochloric acid

A technology for absorption and analysis, hydrochloric acid, applied in chlorine/hydrogen chloride purification, sustainable manufacturing/processing, chemical industry, etc. and process, high economic benefit, simple dehydration and regeneration operation

Inactive Publication Date: 2008-07-09

XINJIANG TIANYE GRP

View PDF0 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to solve the problems of poor treatment and recycling of waste hydrochloric acid, low economic benefits, and environmental pollution in the prior art, and to provide a more thorough treatment and recycling of waste hydrochloric acid, high economic benefits, and low environmental pollution. Hydrochloric acid combined absorption analysis method with small size, reasonable process design and easy operation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0018] The difference between embodiment 2 and embodiment 1 is that the temperature of the desorption tower is 130°C.

Embodiment 3

[0019] The difference between embodiment 3 and embodiment 1 is that the temperature of the desorption tower is 110°C.

Embodiment 4

[0020] Embodiment 4 differs from Embodiment 1 or 2 in that: the combined tower, the hydrogen chloride deep cooler, and the acid mist trap can be omitted to directly produce hydrogen chloride.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

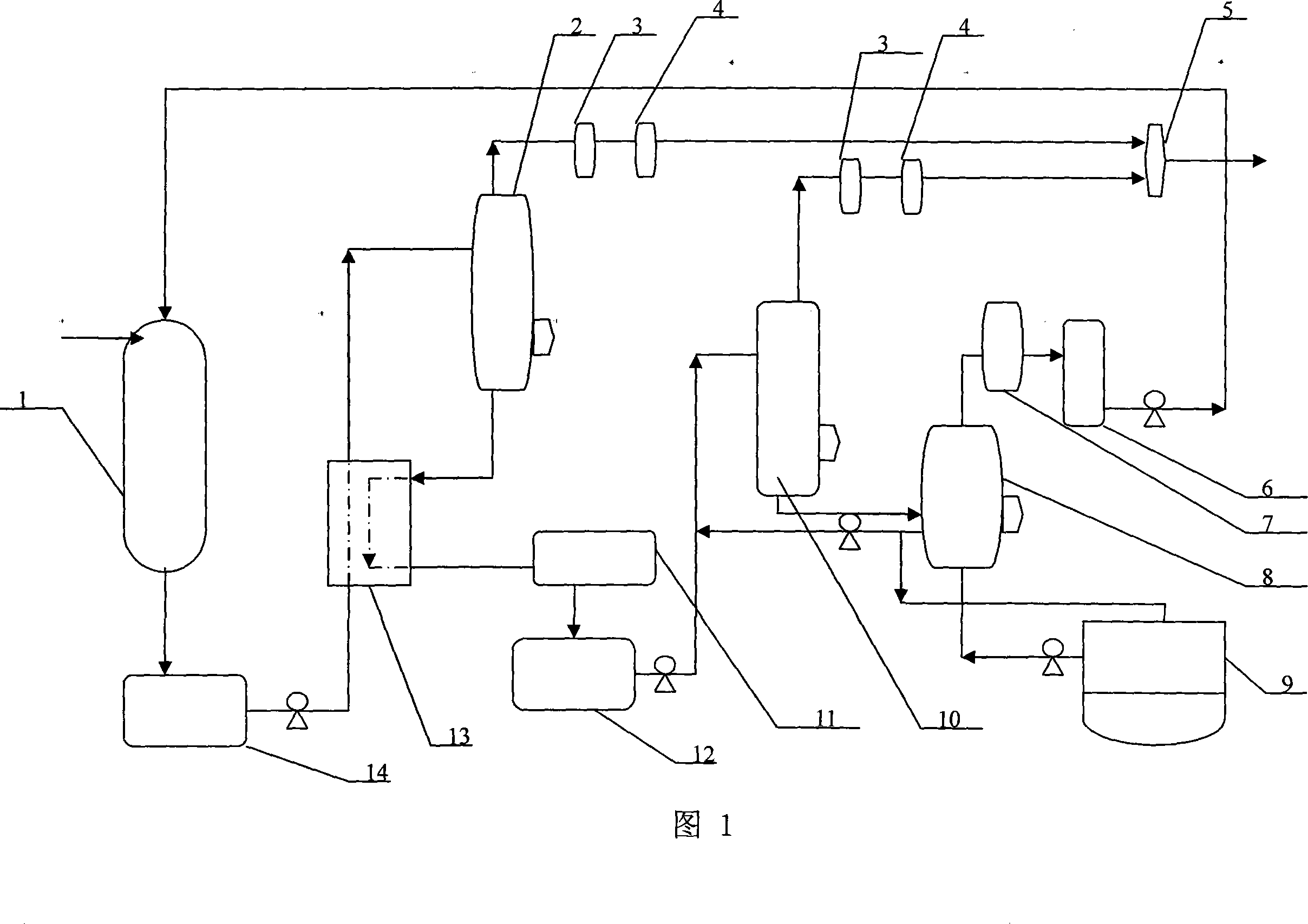

The invention relates to a hydrochloride combined absorption and analytic method, which includes the following steps: concentrated hydrochloric acid in a concentrated hydrochloric acid tank enters into a concentrated acid analytic tower through a pump and a double-effect heat exchanger to be analyzed, and partial hydrogen chloride gas is obtained; the no-analyzed dilute hydrochloric acid enters into a dilute acid tank through the double-effect heat exchanger and a cooler; calcium chloride solution in dilute hydrochloric acid and calcium chloride concentration towers goes through a pump, is mixed and enters into a dilute acid tower to be analyzed, the hydrogen chloride gas is obtained; the dilute calcium chloride solution with trace hydrochloride in a dilute hydrochloride analytic tower enters into the calcium chloride concentration tower to be concentrated, waste water within hydrochloride meeting the emission standard is obtained; the concentrated calcium chloride flows back to a calcium chloride preparing tank. The invention improves the recovery rate (99.99 percent) of the hydrogen chloride, reduces the neutralization procedure, resource waste and environmental pollution of the waste water, and can also used together with the processes of the upstream industry.

Description

technical field [0001] The invention relates to a method for producing hydrogen chloride from hydrochloric acid, in particular to a method for recovering hydrogen chloride from waste hydrochloric acid and reducing pollution. Background technique [0002] At present, in many industrial production processes, such as petroleum, chemical industry, metallurgy, papermaking, machinery, dyes and other industries, a large amount of hydrochloric acid with different concentrations will be produced. Usually, domestic enterprises adopt methods such as reabsorption, storage, and sales to process hydrochloric acid. , because the hydrochloric acid produced contains a certain amount of impurities, the scope of use of hydrochloric acid is limited, not only the price is low but also difficult to sell, and the sale of dilute hydrochloric acid is even more difficult. Some enterprises adopt the method of neutralizing and discharging waste acid, which not only wastes energy and increases the cost ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B7/07

CPCY02P20/10

Inventor 张新力周军宋晓玲安志明张强李国栋张磊崔金宝李春华赵爱民

Owner XINJIANG TIANYE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com