Brine waste water processing reusing device and method

A salt-containing wastewater, pretreatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

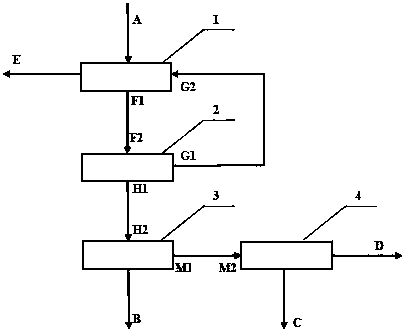

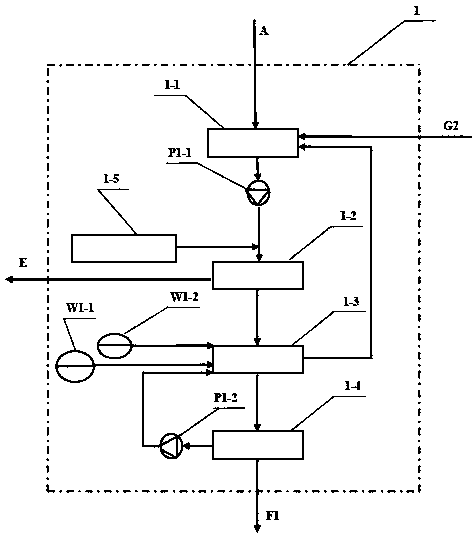

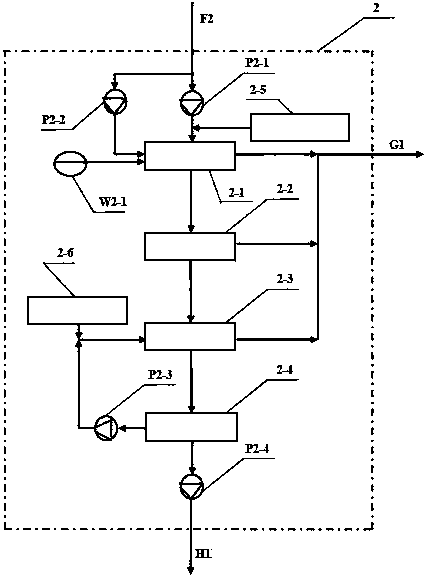

[0032] Such as Figure 6 As shown, the 12240m2 reuse and evaporation water station supporting a large-scale salt chemical enterprise with an annual output of 600,000 tons of soda ash project 3 / D Saline wastewater treatment and reuse project.

[0033] 1. Treated water volume

[0034] In order to recycle water resources and reduce water waste, a saline wastewater treatment and reuse system is designed to recycle the treated production sewage, sewage from the circulating water system and other clean wastewater of the whole plant, etc. The normal amount of reclaimed water reuse is 358m 3 / h, up to 502m 3 / h, the system presses 510m 3 / h design, reuse 497m after final treatment 3 / h, waste salt transported abroad 3m 3 / h, mud discharge 10m 3 / h (use the sludge treatment system of the enterprise's original sewage treatment plant for treatment).

[0035] 2. Influent water quality

[0036] The water inflow of the reuse water system mainly includes: the treated wastewate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com