Zirconium alloy melting and casting method

A casting method and technology of zirconium alloy, applied in the field of zirconium alloy smelting and casting, can solve the problems of high energy consumption and many smelting times, and achieve the effect of improving purification effect, improving mechanical properties and improving metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing the above-mentioned contact material for zirconium alloy, comprising the following steps:

[0041] Step 1, mixing the ceramic powder and reinforcing stabilizer evenly;

[0042] Step 2, wet ball milling for 20-24 hours, drying at 80-100°C and pulverizing;

[0043] Step 3, calcining at 1400-1450°C for 1.5-6 hours, cooling, and pulverizing;

[0044] Step 4, wet ball milling for 24-48 hours, drying at 80-100°C, crushing and screening.

[0045] The present invention also provides a method for preparing a filter medium using the contact material, comprising the following steps:

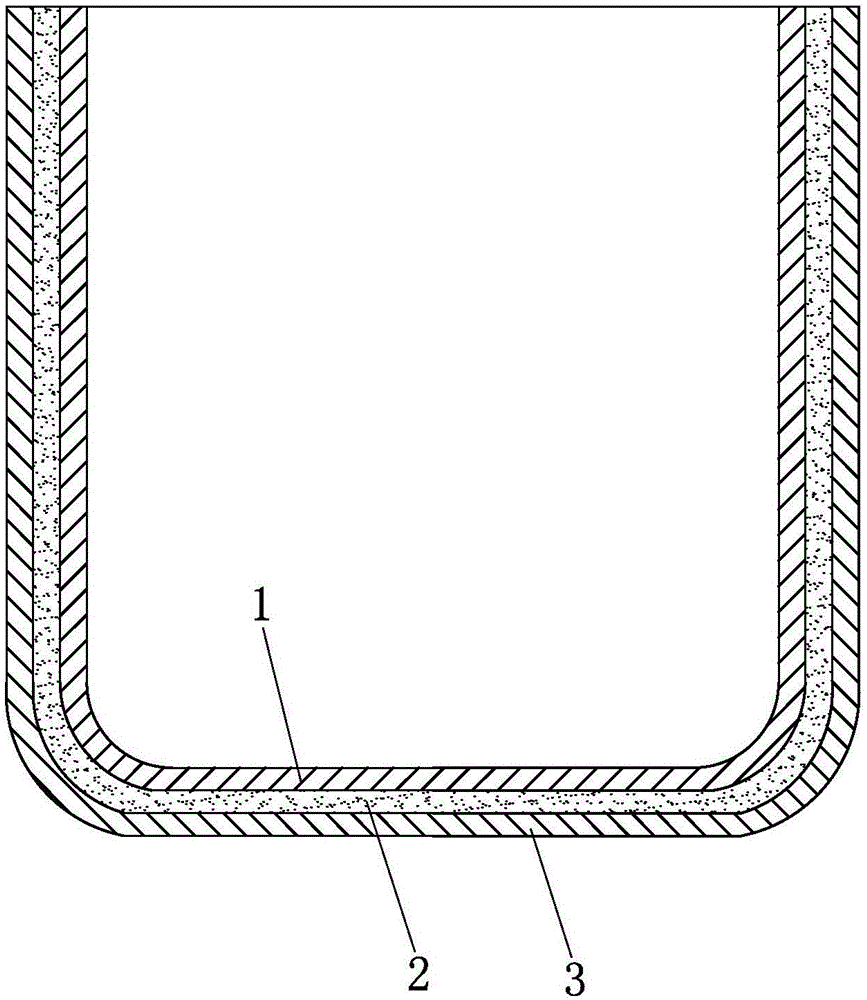

[0046] Step 1, pretreatment, immersing the three-dimensional polyurethane foam sponge skeleton in a NaOH solution with a concentration of 10% to 20% by mass, hydrolyzing it at a temperature of 40 to 60°C for 2 to 4 hours, then repeatedly rubbing and rinsing with clean water, and then drying it in the air, thereby clean the sponge;

[0047...

Embodiment 1

[0068] The contact material of the present embodiment is made of ceramic powder and reinforcing stabilizer, and said ceramic powder is made of MgO and ZrO 2 According to the molar ratio of 6:100, the strengthening and stabilizing agent is 0.5% of the ceramic powder by weight, and the strengthening and stabilizing agent is preferably cerium-rich rare earth. The cationic radius of MgO and Zr 4+ close, they are in ZrO 2 The solubility in the medium is very large, and it can be mixed with ZrO 2 Form substitutional solid solutions of monoclinic, tetragonal and cubic crystal forms.

[0069] The preparation method of the contact material is as follows:

[0070] Step 1, mixing the ceramic powder and reinforcing stabilizer evenly;

[0071] Step 2, wet ball milling for 20 hours, drying in an oven at 80°C and pulverizing;

[0072] Step 3, calcining at 1400°C for 1.5 hours, cooling, and pulverizing, so that the contact material after treatment is uniform and the phase body is stable....

Embodiment 2

[0099] The contact material of the present embodiment is made of ceramic powder and reinforcing stabilizer, and said ceramic powder is made of MgO and ZrO 2 According to the molar ratio of 8.5:100, the strengthening and stabilizing agent is 0.8% of the ceramic powder by weight, and the strengthening and stabilizing agent is preferably cerium-rich rare earth.

[0100] The preparation method of the contact material is as follows:

[0101] Step 1, mixing the ceramic powder and reinforcing stabilizer evenly;

[0102] Step 2, wet ball milling for 22 hours, drying in an oven at 90°C and pulverizing;

[0103] Step 3: calcining at 1425°C for 2 hours, cooling, and pulverizing, so that the contact material after treatment is uniform and the phase body is stable. Due to the solid solution treatment in advance, it lays a foundation for subsequent sintering uniformity, and the strength of the material is higher;

[0104] Step 4, wet ball milling for 36 hours, drying at 90°C, passing thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com