Process for recovering organic matters in hydrogen chloride gas and equipment used by same

A technology for hydrogen chloride gas and organic matter, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of high equipment maintenance cost, high energy consumption, high one-time investment in equipment, and reduce production costs and maintenance costs. , The effect of saving equipment investment and saving equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

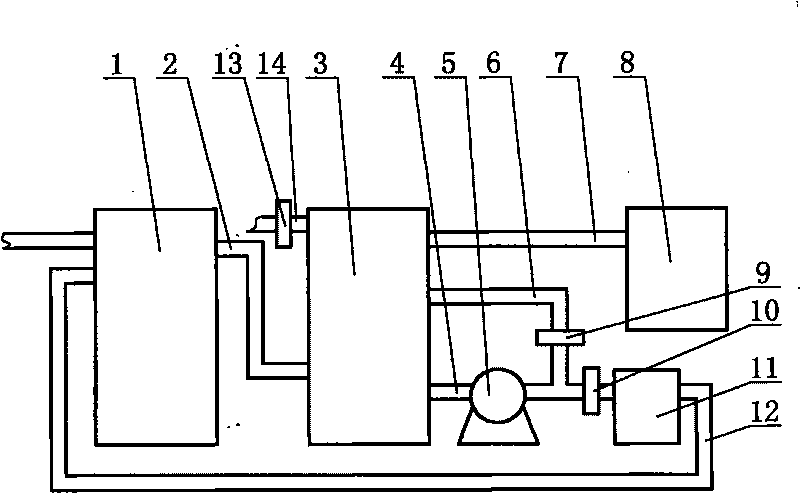

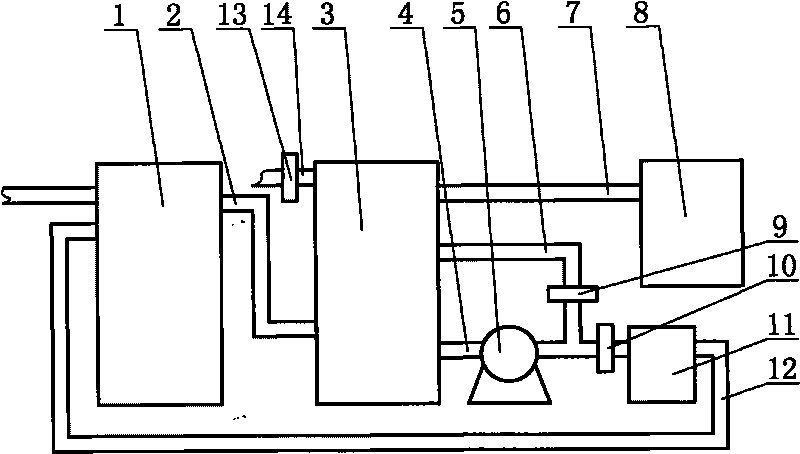

[0016] The present invention will be further described with reference to accompanying drawing:

[0017] A kind of technique of reclaiming organic matter in hydrogen chloride gas according to the present invention comprises the following process steps:

[0018] (1) Input the mixed gas produced by the methane chloride generating device into the organic matter absorption tower. The mixed gas mainly includes gas phase organic matter and hydrogen chloride gas. The organic matter is mainly monochloromethane and dichloromethane. The organic matter absorption tower is fed into Methane chloride is used as an absorbent to absorb the mixed gas, the organic matter in the mixed gas is integrated into the methane chloride, and the hydrogen chloride gas in the mixed gas is discharged;

[0019] (2) The hydrogen chloride gas discharged from the organic matter absorption tower is sent to the hydrogen chloride absorber, and hydrochloric acid is used in the hydrogen chloride absorber to absorb th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com