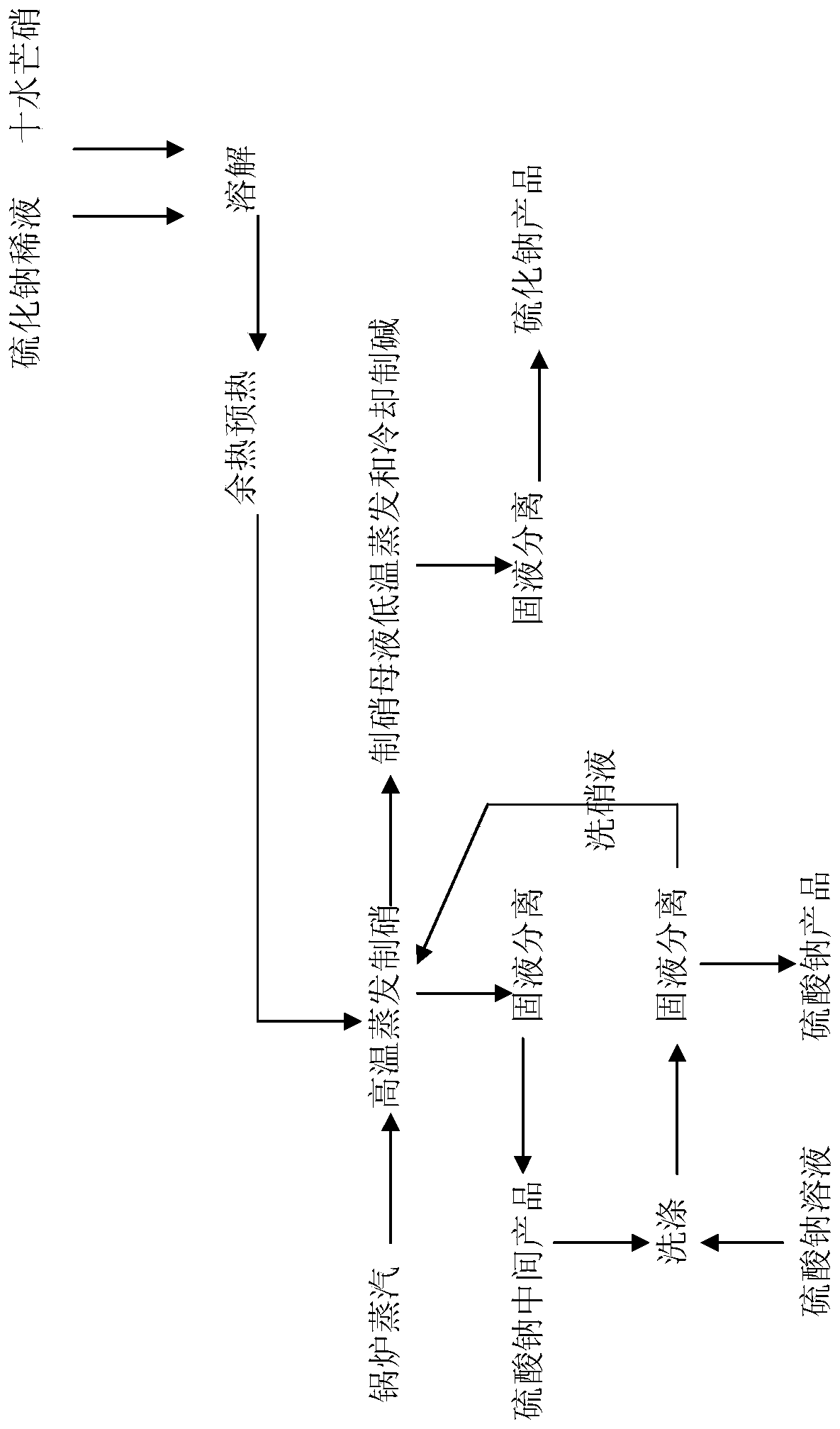

A kind of sodium sulfide and sodium sulfate production process of dilute alkali sulfide solution and Glauber's salt decahydrate

A technology of soda sulfide and sodium sulfate, which is applied in the fields of alkali metal sulfite/sulfate purification, sulfur compounds, chemical instruments and methods, etc., and can solve frequent fouling of evaporation tanks, product quality, high steam consumption, low raw material concentration, etc. problems, to achieve the effect of high quality main and by-products, low investment, concise and reasonable process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: take 100m 3 Dilute alkali sulfide (Na 2 S 55g / l) dissolves 82.5 tons of Glauber's salt decahydrate (Na 2 SO 4 10H 2 O, containing Na 2 SO 4 40%) to get 110m 3 Brine (Na 2 S 50g / l, Na 2 SO 4 300g / l) as raw material, after entering the high-temperature nitrification evaporation system to evaporate and separate to obtain 33 tons of sodium sulfate (Na 2 SO 4 ) intermediate product (poor whiteness) and 6.9m 3 High temperature nitrification mother liquor (Na 2 S800g / l, Na 2 SO 4 0.40g / l), the evaporation temperature of high-temperature nitric acid production is 130°C; 6.9m 3 High temperature nitrification mother liquor (Na 2 S 800g / l, Na 2 SO 4 0.40g / l) into the low-temperature alkali-making evaporative cooling system to evaporate and cool and separate to obtain 5.5 tons of sodium sulfide (Na 2 S) intermediate products and 0.08m 3 Low temperature alkali making mother liquor (Na 2 S 261g / l, Na 2 SO 4 36g / l), 0.08m 3 Low temperature alk...

Embodiment 2

[0018] Embodiment 2: take 100m 3 Dilute alkali sulfide (Na 2 S 55g / l) dissolves 82.5 tons of Glauber's salt decahydrate (Na 2 SO 4 10H 2 O, containing Na 2 SO 4 40%) to get 110m 3 Brine (Na 2 S 50g / l, Na 2 SO 4 300g / l) as raw material, after entering the high-temperature nitrification evaporation system to evaporate and separate to obtain 33 tons of sodium sulfate (Na 2 SO 4 ) intermediate product (poor whiteness) and 12.2m 3 High temperature nitrification mother liquor (Na 2 S 450g / l, Na 2 SO 4 4.7g / l), the evaporation temperature of high-temperature nitric acid production is 80°C; 12.2m 3 High temperature nitrification mother liquor (Na 2 S 450g / l, Na 2 SO 4 4.7g / l g / l) enters the low-temperature soda-making evaporative cooling system and separates after evaporation and cooling to obtain 5.5 tons of sodium sulfide (Na 2 S) intermediate products and 0.96m 3 Low temperature alkali making mother liquor (Na 2 S 200g / l, Na 2 SO 4 60g / l), 0.96m 3 Low te...

Embodiment 3

[0019] Embodiment 3: take 100m 3 Dilute alkali sulfide (Na 2 S 55g / l) dissolves 82.5 tons of Glauber's salt decahydrate (Na 2 SO 4 10H 2 O, containing Na 2 SO 4 40%) to get 110m 3 Brine (Na 2 S 50g / l, Na 2 SO 4300g / l) as raw material, after entering the high-temperature nitrification evaporation system to evaporate and separate to obtain 33 tons of sodium sulfate (Na 2 SO 4 ) intermediate product (poor whiteness) and 5.0m 3 High temperature nitrification mother liquor (Na 2 S1100g / l, Na 2 SO 4 0.2g / l), the evaporation temperature of high-temperature nitric acid production is 170°C; 5.0m 3 High temperature nitrification mother liquor (Na 2 S 1100g / l, Na 2 SO 4 0.2g / l) into the low-temperature alkali-making evaporative cooling system to evaporate and cool and separate to obtain 5.5 tons of sodium sulfide (Na 2 S) intermediate products and 0.2m 3 Low temperature alkali making mother liquor (Na 2 S395g / l, Na 2 SO 4 5.0g / l), 0.2m 3 Low temperature alkali ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com