Fracturing flow-back fluid treatment method

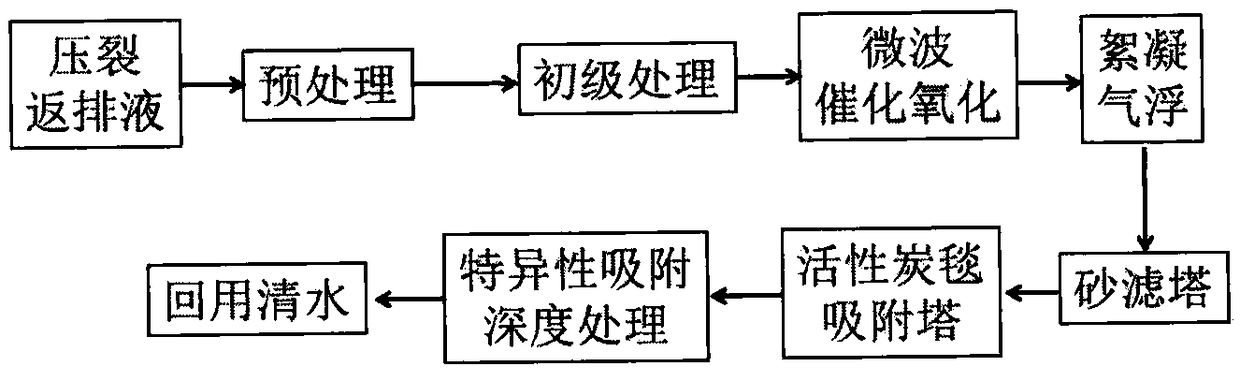

A technology of fracturing flowback fluid and treatment method, which is applied in the direction of filtration treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of simple process and other problems, and achieve the effect of easy technical conditions, thorough treatment and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

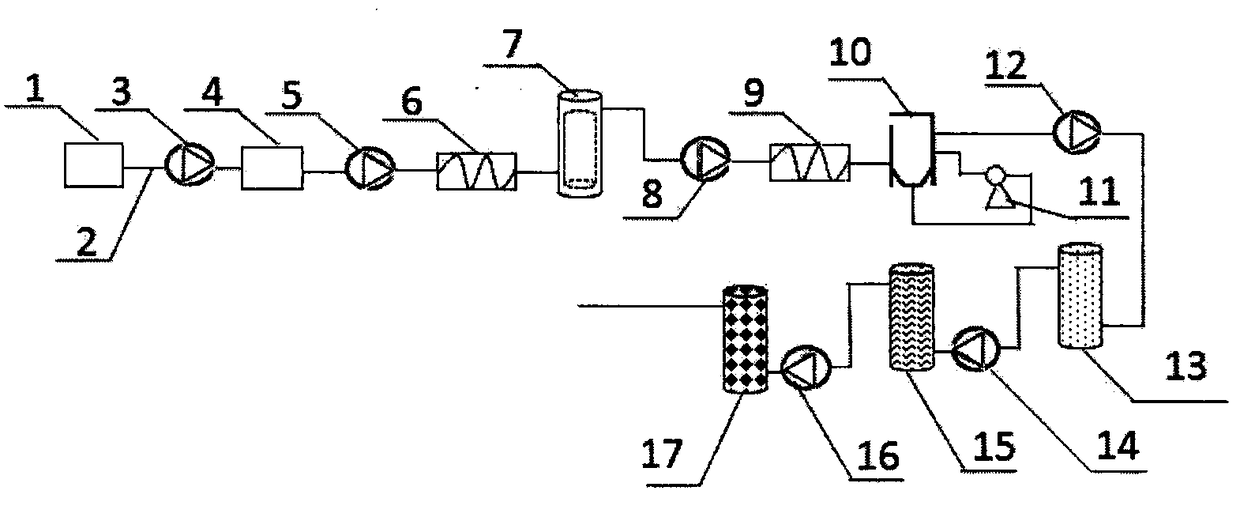

[0031] A method for treating fracturing flowback fluid according to the present invention, the device involved in the method is composed of a water pretreatment reactor 1, a pipeline 2, a first water pump 3, a primary treatment reactor 4, and a second water pump 5. The first dosing mixer 6, the microwave reactor 7, the third water pump 8, the second dosing mixer 9, the air flotation device 10, the dissolved air pump 11, the fourth water pump 12, the sand filter tower 13, the fifth Water pump 14, active carbon blanket adsorption tower 15, the 6th water pump 16 and specific resin adsorption tower 17 are made up of, at one end of microwave reactor 7 respectively through pipeline 2 and first dosing mixer 6, primary treatment reactor 4 and water The pretreatment reactors 1 are connected in series, the first water pump 3 is provided between the water pretreatment reactor 1 and the primary treatment reactor 4, and the second water pump 5 is provided between the primary treatment react...

Embodiment 2

[0048] The device described in this embodiment is carried out according to embodiment 1, and the specific operation is carried out according to the following steps:

[0049] Using this method to treat guar gum: the guar gum-based fracturing flowback fluid is dark brown, with a high oil content, a pH value of 5.18, a COD of 2260 mg / L, and a concentration of suspended solids of 1700 mg / L;

[0050] Pretreatment of fracturing flowback fluid:

[0051] a. Add 100ppm of clay to the guar gum-based fracturing flowback fluid, stir evenly, enter the pretreatment reactor 1, perform pretreatment, and remove the large solid particles and upper oil slick in it by static precipitation;

[0052] Primary processing:

[0053] b. The product treated in step a enters the primary treatment reactor 4 through the first water pump 3, and hydrochloric acid is added to adjust the pH value of the solution to 6.8;

[0054] Microwave catalytic oxidation treatment:

[0055] c. The solution obtained in st...

Embodiment 3

[0065] The device described in this embodiment is carried out according to embodiment 1, and the specific operation is carried out according to the following steps:

[0066] Pretreatment of fracturing flowback fluid:

[0067] a. Add 90ppm of clay to the guar gum-based fracturing flowback fluid, stir evenly, enter the pretreatment reactor 1, perform pretreatment, and remove the large solid particles and upper oil slick in it by static precipitation;

[0068] Primary processing:

[0069] b. The product treated in step a enters the primary treatment reactor 4 through the first water pump 3, and hydrochloric acid is added to adjust the pH value of the solution to 6.5;

[0070] Microwave catalytic oxidation treatment:

[0071] c, the solution obtained in step b enters the first dosing mixer 6 through the second water pump 5, adds sensitizer carbon fiber short fiber 80ppm, mixes evenly, enters the microwave reactor 7, and the microwave reactor 7 is a hollow cavity structure, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com