Band steel stretch-bending straightening system capable of controlling elongation rate and control method thereof

A technology of stretch-bending straightening and elongation, applied in the direction of elongation control, etc., can solve the problems of low production efficiency of the unit, difficulty in mechanical manufacturing and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

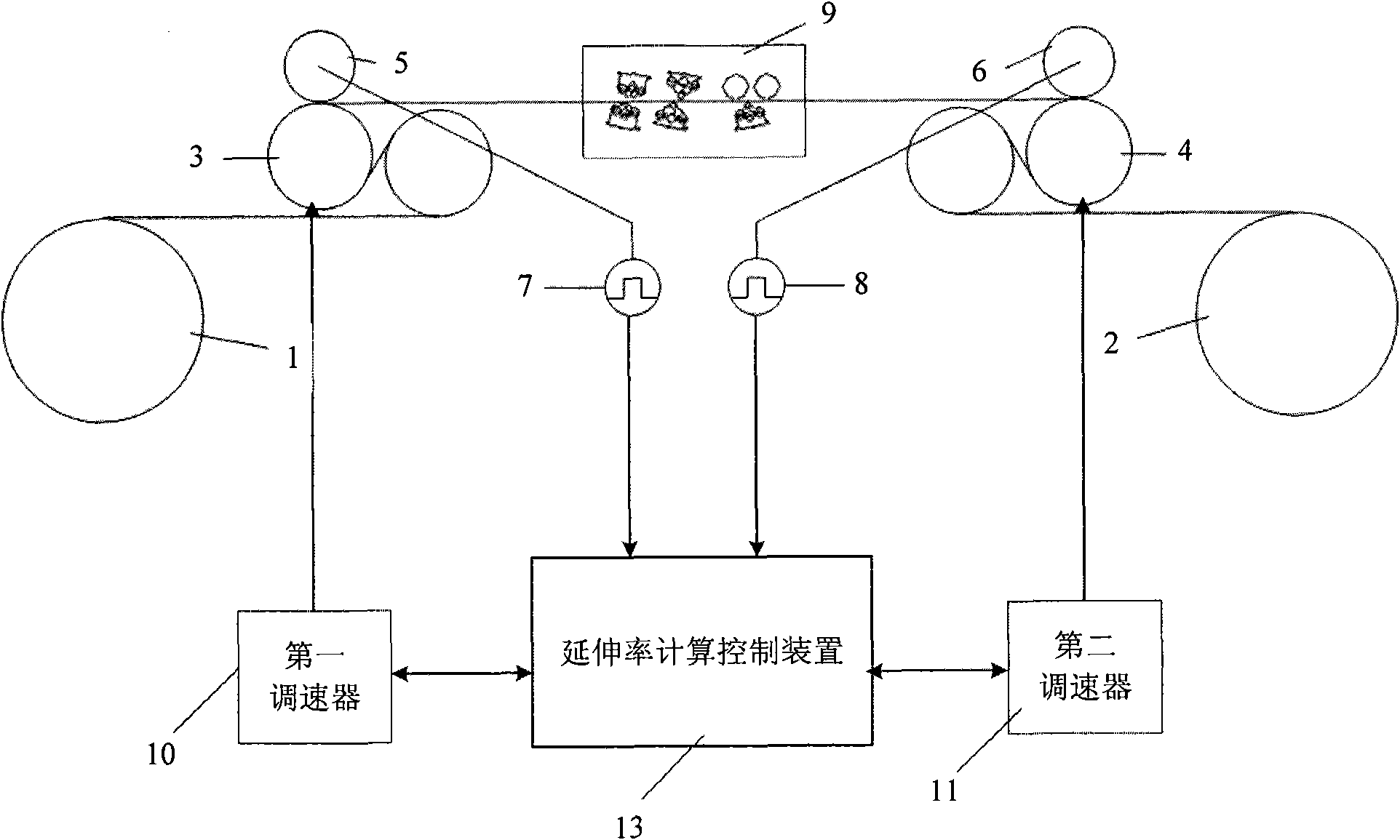

[0032] like figure 1 As shown, a strip bending straightening system with controllable elongation includes unwinding 1, entrance roll 3, stretch leveling machine 9, exit roll 4, winding 2, and respectively according to the running direction of the strip. The first motor and the second motor that drive the entrance roller 3 and the exit roller 4 are characterized in that they also include:

[0033] Strip inlet and outlet speed measuring device 12 for measuring the strip inlet and outlet speed;

[0034] A first governor 10, connected to the first motor, for controlling the speed of the first motor;

[0035] The second governor 11 is connected with the second motor and is used to control the speed of the second motor;

[0036] The elongation rate calculation control device 13 is connected with the strip steel inlet and outlet speed measuring device 12, the first speed governor 10, and the second speed governor 11, and stores the preset elongation rate δ of the strip steel in it....

Embodiment 2

[0044] A strip bending straightening system with controllable elongation, except for the following differences, other parts are the same as the first embodiment:

[0045] The elongation calculation and control device 13 also stores the maximum elongation deviation value δ 0 , when the absolute value of Δδ is greater than δ 0 , adjust the speeds of the first motor and the second motor respectively through the first governor 10 and the second governor 11 according to Δδ until |Δδ|0 or |Δδ|=δ 0 . That is, when the preset elongation δ 2 and actual elongation δ 1 When the deviation Δδ of Δδ is within the required dead zone range, the speeds of the entrance roller 3 and the exit roller 4 are not adjusted. When the actual elongation δ 1 and preset elongation δ 2 When the deviation Δδ is outside the required dead zone range, the size of the adjustment amount of the speed difference between the entrance roller 3 and the exit roller 4 is determined according to the deviation Δδ, a...

Embodiment 3

[0048] An automatic control method for strip elongation, using the system described in Embodiment 1, comprising the steps:

[0049] Step 1, set the strip preset elongation δ 2 ;

[0050] Step 2, measuring the entrance speed and exit speed of the stretch bending straightener;

[0051] Step 3, calculate the actual elongation δ of the strip according to the entrance speed and exit speed of the tension leveling machine 1 ;

[0052] Step 3, compare the actual elongation δ of the strip 1 and the preset elongation δ of the strip 2 , calculate δ 1 and δ 2 the difference;

[0053] Step 4, according to δ 1 and δ 2 The difference value controls the inlet speed and outlet speed of the stretch bending straightening machine.

[0054] The automatic control method of strip elongation provided in this embodiment is to use preset elongation δ 2 and measured actual elongation δ 1 The difference between elongation produces an additional speed given value to change the speed of entranc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com