Planar fiber leftover material recycling and reusing method

A leftover, surface-like technique

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

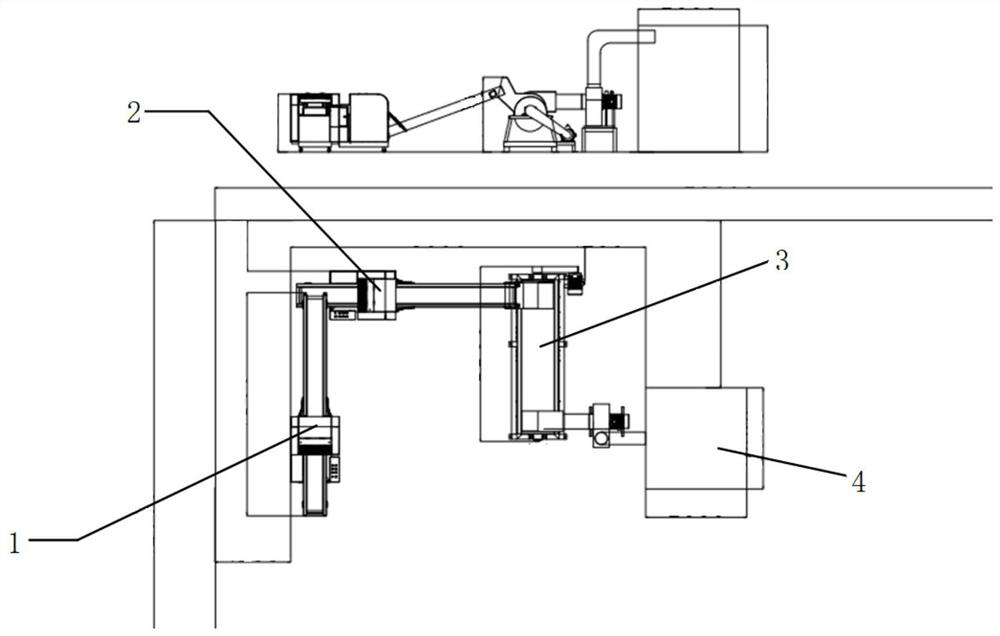

[0023] In this embodiment, the raw material is a mixture of surface fiber fabrics, including two-dimensional fabric material scraps such as plain weave, twill weave, satin weave, and multi-axial cloth. The fiber is at least one of polyester fiber, carbon fiber, polyester fiber, glass fiber, cotton fiber, aramid fiber, hybrid fiber, hybrid fiber, and composite fiber. This embodiment adopts figure 1 The equipment shown performs integrated processing and production, figure 1 in:

[0024] Shearing machine 1:

[0025] It is used to process the recycled surface fiber into a longitudinal strip fiber with a certain width according to the proportional size requirements;

[0026] Shearing machine 2:

[0027] Used to cut the longitudinal strip fibers of the shearing machine 1 into block fibers again in the transverse direction according to a certain required size;

[0028] Fiber splitter 3:

[0029] It is used to split the lumpy fibers of a certain size cut into by the shearing machine 2 to spl...

Embodiment 2

[0041] The loose short carbon fiber raw material made through the process of step a-f of Example 1 is made into an areal density of 50g / m 2 A fiber felt with a certain needle-punch density, which is then compounded to prepare composite parts such as automobiles.

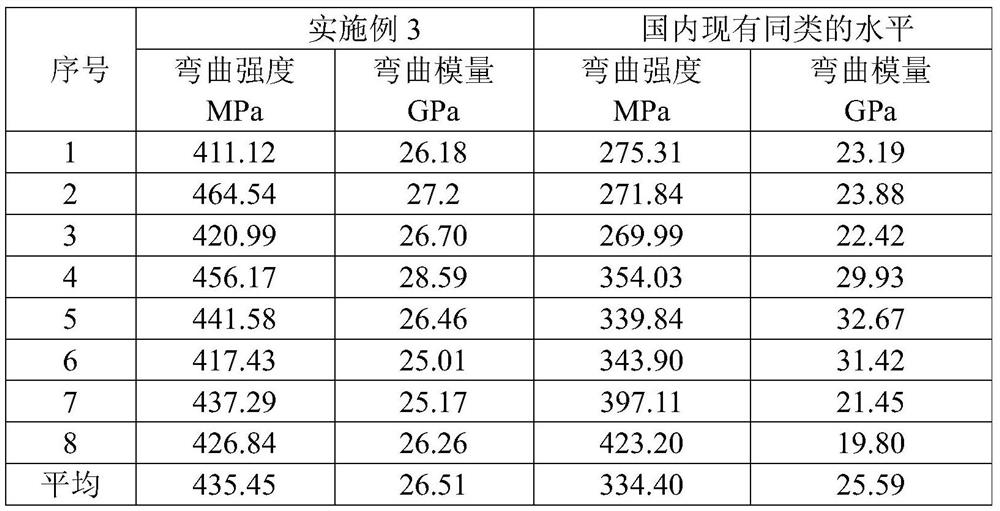

Embodiment 3

[0043] The loose short carbon fiber raw material made through the process of step a-f of Example 1 is made into a fiber content of 300g / m 2 The prepreg felt with a certain needle punch density. The prepreg felt can be directly made into various composite material components through the hot pressing process.

[0044] The core of this patented technology is that no matter what kind of flat fiber leftovers, it can be cut into fixed-length fiber sheets by linkage, and then the fiber is dispersed and recycled to form a loose and certain length. This kind of short fiber material is processed into fiber non-woven felt, fiber needled felt, fiber felt prepreg, SMC, BMC and other products.

[0045] Linkage cutting is to perform a fixed-length cutting in one axial direction for the planar fiber leftover material according to the required length; then, to the above-mentioned already cut fiber strips, perform secondary continuous fixed-length cutting in the direction perpendicular to the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com