Method for treating and recycling TBBP (tetrabromobisphenol)-A production wastewater

A technology for producing tetrabromobisphenol and waste water, which is applied in the fields of natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., which can solve the difficulties of chlorobenzene recovery, reduce the process operation cycle, and the difficulty of biological cultivation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

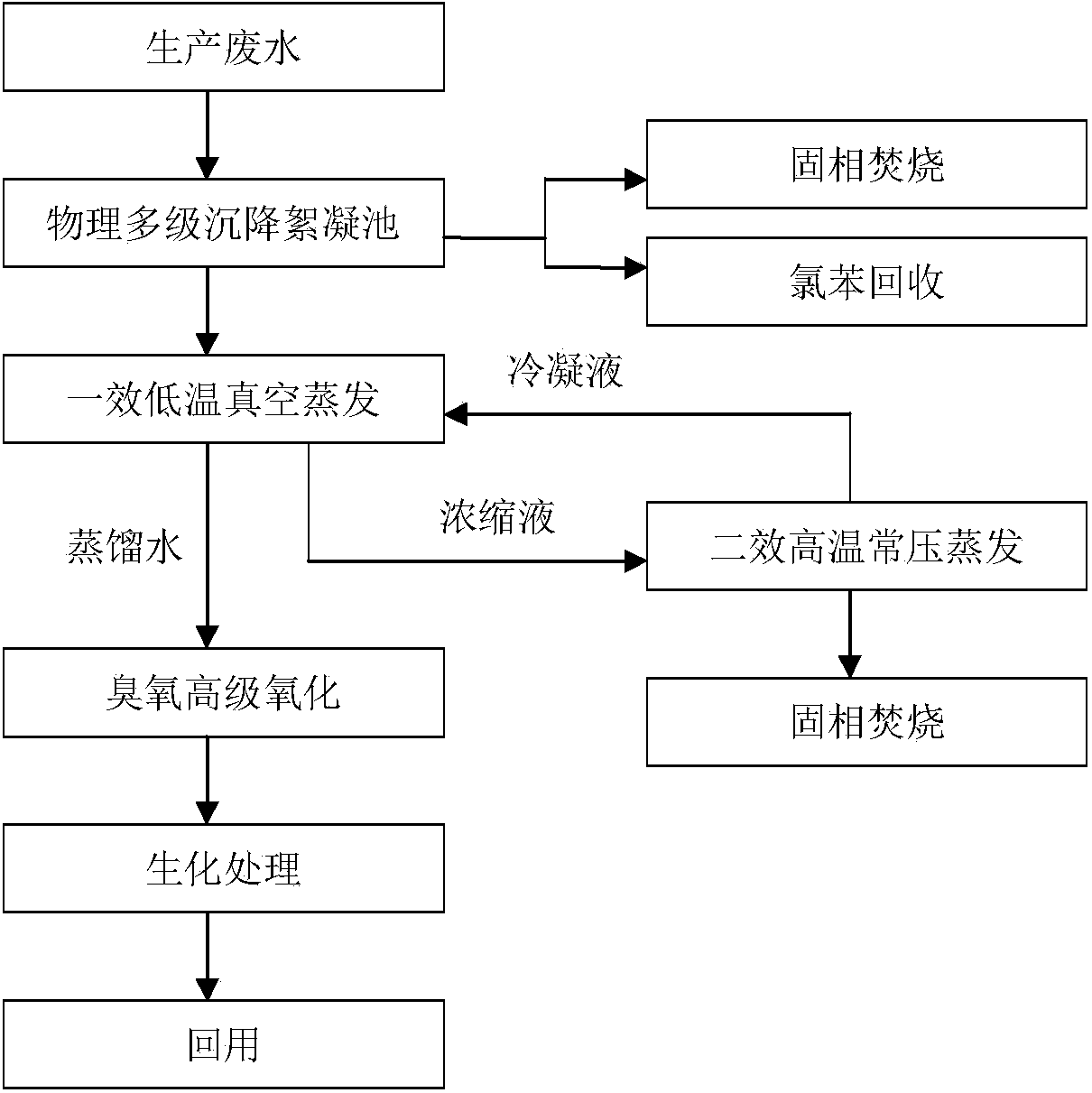

[0017] A method for the treatment and recycling of tetrabromobisphenol A production wastewater, including physical multi-stage sedimentation and flocculation recovery, two-effect high and low temperature evaporation desalination, ozone advanced oxidation and biochemical treatment several main steps, mainly including the following process steps:

[0018] (1) Physical multi-stage sedimentation and flocculation: Tetrabromobisphenol A wastewater is subjected to three-stage sedimentation treatment. The first-stage sedimentation is cooling sedimentation, the second-stage sedimentation is flocculation sedimentation, and the third-stage sedimentation is overflow sedimentation. The physical cooling of the wastewater through the first stage of sedimentation promotes the precipitation of some chlorobenzene and phenolic substances in the wastewater. The precipitated chlorobenzene is recovered by low-temperature flash technology, and the purity of recovered chlorobenzene can reach more than ...

Embodiment 2

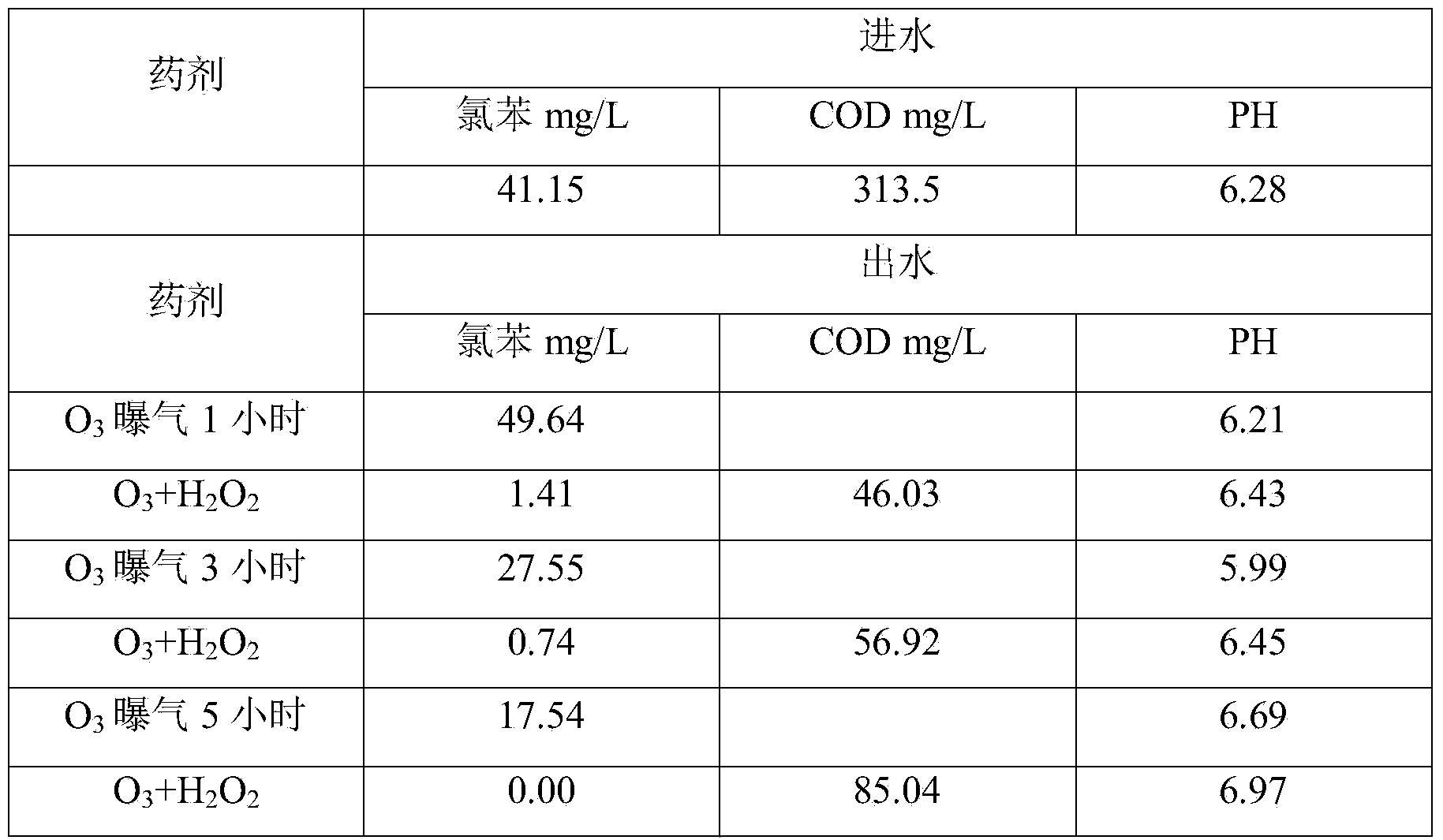

[0024] Its concrete operation process is the same as embodiment 1, only the aeration time of feeding ozone in step (4) is changed to 1 hour, and other conditions are all the same as embodiment 1. After aeration with ozone for 1 hour, add ozone and hydrogen peroxide for oxidation. The physical and chemical indicators of the wastewater are: chlorobenzene: 1.41mg / L, COD: 46.03mg / L, PH value: 6.43 (see Table 2 for specific values) .

Embodiment 3

[0026] Its specific operation process is the same as that of Example 1, only the aeration time of feeding ozone in step (4) is changed to 5 hours, and other conditions are all the same as in Example 1. After 5 hours of aeration with ozone, add ozone and hydrogen peroxide for oxidation. The physical and chemical indicators of the wastewater are: chlorobenzene: 0mg / L, COD: 85.04mg / L, PH value: 6.97 (see Table 2 for specific values).

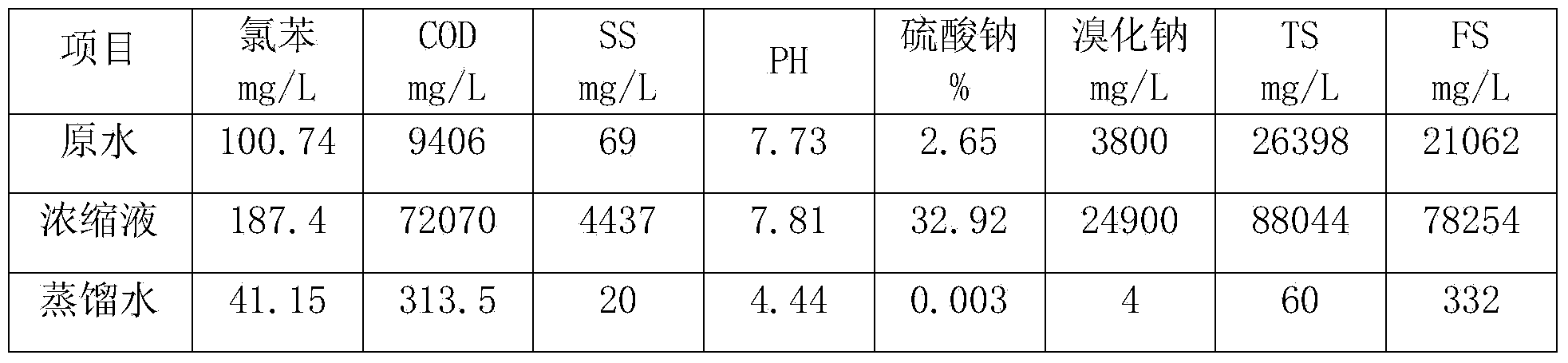

[0027] Table 1: Various indicators of one-effect low-temperature vacuum evaporation

[0028]

[0029] In the table:

[0030] SS: Refers to solid substances suspended in water, including insoluble inorganic substances, organic substances, silt, clay, microorganisms, etc.

[0031] FS: Refers to non-dissolved solids in sewage.

[0032] TS: is the sum of dissolved solids and non-dissolved solids in sewage. It reflects the total concentration of solids in sewage. The analysis of influent and effluent solids can reflect the effect of sewage treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com